Metal Strip Suppliers Manufacturer

An outstanding China metal strip manufacturer has exported to more than 40 countries.

Looking forward to your choosing us as your steel strip supplier in China!

Our Metal Strip Products

Our strip products cover a variety of materials, including stainless steel, aluminum alloy, copper, etc., with excellent corrosion resistance, strength, and workability. Whether you need raw material supply or customized processing, we can provide you with a one-stop service to ensure that your needs are best met.

The following are the four major categories of metal raw materials that our company can provide. If you have any questions, please free to contact us, We will quote for you within 24 hours! Looking forward to becoming your China Metal Strip Suppliers and Manufacturers!

We stock and sell steel strips in all forms and sizes. If you don’t find the steel strip you need here, please contact us directly.

Steel Strip Suppliers

Huaxiao Metal stands out as your dependable supplier and manufacturer of high-quality metal strips. We cater to diverse industries, including construction, automotive, electronics, aerospace, and more, ensuring that our products meet the highest standards.

With state-of-the-art production facilities and a dedicated technical team, we specialize in delivering metal strips tailored to your specific requirements. Whether you need precise dimensions, unique materials, or intricate processing techniques, our expertise allows us to provide customized solutions that match your exact needs.

Choose Huaxiao Metal for a trustworthy partner in sourcing steel strips and benefiting from bespoke processing services. Contact us today to explore how we can meet your project demands with our professional solutions!

Why Choose Us As Your Metal Strip Suppliers in China?

Product Quality

Our company's raw materials come from China's TISCO, Baosteel, Delong, and other steel manufacturers. We strictly control the quality of products to ensure that the products received by customers meet international standards and customer requirements.

Delivery Period

We have an efficient supply chain and a professional team, which can process customers' orders in a timely manner and ensure on-time delivery. The specific delivery cycle depends on the product type and quantity, and we will give the accurate delivery time when the customer places an order.

Price

Our metal strip price is competitive in the market, and we will make a reasonable price according to the customer's order quantity, delivery cycle and other factors. We will try our best to provide customers with the best price while ensuring that product quality and delivery time are not affected.

Customer Service

We have a professional customer service team that can answer customer questions and solve problems in a timely manner. We provide a full range of services from procurement to delivery, and provide customers with after-sales service. Customer satisfaction is our highest pursuit.

Trust Huaxiao Metal as Your Reliable Metal Strip Supplier and Manufacturer!

Things to Consider When Purchasing from China Steel Strip Manufacturers

Purchasing steel strips from China can be a cost-effective and efficient solution for your manufacturing needs. However, it’s essential to consider several factors to ensure you receive high-quality products and reliable service. Here are key points to keep in mind:

Quality Standards

- Certifications: Ensure the manufacturer has relevant certifications (ISO, CE, etc.) that guarantee adherence to international quality standards.

- Material Specifications: Verify that the steel strips meet the required material specifications and standards for your application.

Manufacturer Reputation

- Reviews and References: Look for reviews and ask for references from other customers to gauge the manufacturer’s reputation and reliability.

- Experience: Consider the manufacturer’s experience in producing steel strips, particularly in your industry.

Production Capabilities

- Technology and Equipment: Ensure the manufacturer uses advanced production technology and equipment to produce high-quality steel strips.

- Customization: Check if the manufacturer can provide customized sizes, thicknesses, and finishes to meet your specific requirements.

Quality Control

- Inspection Processes: Inquire about the manufacturer’s quality control processes, including in-house testing and third-party inspections.

- Defect Rates: Ask for information on defect rates and how the manufacturer handles quality issues.

Pricing and Payment Terms

- Competitive Pricing: Compare pricing from multiple manufacturers to ensure you are getting a competitive rate.

- Payment Terms: Understand the payment terms, including deposit requirements, payment milestones, and currency options.

Lead Times and Delivery

- Production Lead Time: Confirm the production lead time to ensure it aligns with your project timeline.

- Shipping and Logistics: Discuss shipping methods and logistics, including options for international shipping, to ensure timely and cost-effective delivery.

Compliance with Regulations

- Export Regulations: Verify that the manufacturer complies with export regulations and can provide necessary documentation for customs clearance.

- Environmental and Safety Standards: Ensure the manufacturer adheres to environmental and safety regulations to avoid legal issues.

Sample Orders

- Trial Orders: Consider placing a small trial order to evaluate the quality, service, and reliability before committing to a larger purchase.

Partnership Potential

- Long-term Relationship: Assess the potential for a long-term partnership, which can offer benefits like better pricing, priority production, and consistent quality.

Trust Huaxiao Metal as Your Reliable Metal Strip Supplier and Manufacturer!

FAQ

What are Steel Strips Used for?

Steel strips are versatile and widely used across various industries due to their strength, durability, and flexibility. Here are some common applications:

Automotive Industry

- Body Panels: Used in the manufacturing of car body panels and structural components.

- Exhaust Systems: Employed in the production of exhaust system components.

- Chassis Parts: Integral in creating the chassis and other underbody parts.

Construction

- Building Frameworks: Utilized in the construction of structural frameworks and support systems.

- Roofing and Cladding: Applied in roofing and exterior cladding for buildings.

- Reinforcements: Used as reinforcement materials in concrete structures.

Packaging

- Steel Strapping: Used for bundling and securing goods during transportation and storage.

- Drums and Barrels: Employed in the manufacturing of drums and barrels for packaging liquids and bulk materials.

Electrical and Electronics

- Transformer Cores: Utilized in the production of transformer cores and electrical laminations.

- Cable Armoring: Provides protective armoring for electrical cables.

- Electronic Components: Used in various electronic components and enclosures.

Consumer Goods

- Appliances: Integral in the manufacturing of household appliances such as refrigerators, washing machines, and ovens.

- Furniture: Used in the production of metal furniture and fixtures.

Agriculture

- Equipment Manufacturing: Applied in the production of agricultural machinery and equipment.

- Fencing: Used in the creation of durable and long-lasting fencing materials.

Aerospace

- Aircraft Components: Utilized in the manufacturing of certain aircraft components and structures.

Industrial Equipment

- Machinery Parts: Employed in the production of various industrial machinery parts and tools.

- Conveyor Belts: Used in the fabrication of conveyor belts and systems.

Medical Devices

- Surgical Instruments: Used in the manufacturing of surgical instruments and medical devices.

- Equipment: Applied in the construction of medical equipment and apparatus.

Miscellaneous

- Blades and Saws: Used in the production of cutting tools such as blades and saws.

- Fasteners: Utilized in the creation of fasteners like screws, bolts, and nuts.

How Heavy are Steel Strips?

The weight of steel strips can vary widely depending on their dimensions (thickness, width, and length) and the type of steel used (e.g., carbon steel, stainless steel). Generally, the weight of steel strips is calculated based on their volume (area × thickness × density of steel). Here are approximate weight ranges for typical steel strips:

- Thin Steel Strips (0.1-1.5 mm thick): About 1.2-18 kg/m²

- Medium Steel Strips (1.5-3 mm thick): About 18-36 kg/m²

- Thicker Steel Strips (3-6 mm thick): About 36-72 kg/m²

These weights are approximate and can vary based on specific dimensions and steel grade. For precise weight calculations, it’s essential to consider the exact dimensions and density of the specific steel material being used.

How are Steel Strips Made?

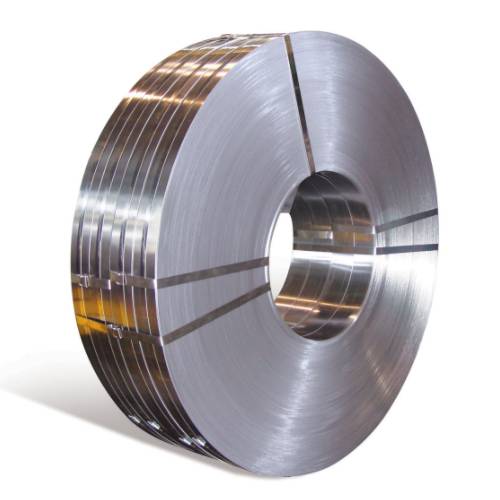

Steel strips are typically produced from coils of steel through a process that involves cutting and slitting the coil into strips. Here’s how steel strips are made from coils:

Coil Production:

Steel Melting: Raw materials such as iron ore and recycled scrap metal are melted in a furnace to produce molten steel.

Continuous Casting: The molten steel is cast into large slabs, which are then rolled into coils of various thicknesses and widths.

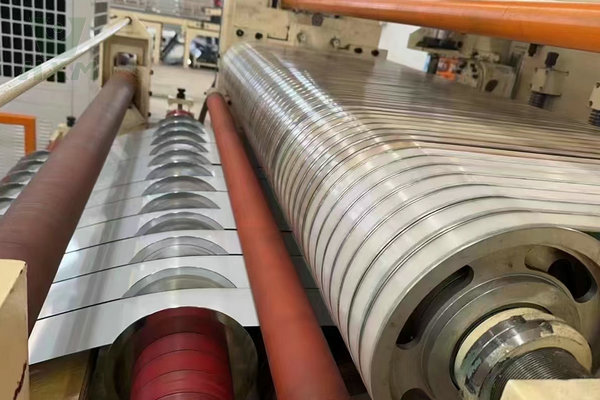

Coil Slitting:

Uncoiling: The steel coils are uncoiled, often using a decoiling machine, to feed into the slitting line.

Slitting: In the slitting line, the coil passes through rotary knives that slit it into strips of the desired width.

Recoiling: Each slit strip is then recoiled into individual coils or wound onto spools.

Surface Treatment:

Depending on the application, the steel strips may undergo surface treatments such as pickling (acid treatment) or coating (e.g., galvanization) to enhance corrosion resistance or improve surface finish.

Quality Control:

Throughout the slitting process, quality control measures ensure that the steel strips meet precise dimensional tolerances and surface quality standards.

Packaging and Distribution:

![]()

After inspection and quality assurance checks, the steel strips are packaged for shipment to customers or further processing facilities.

This coil slitting process enables metal manufacturers to efficiently produce steel strip in different widths and thicknesses to meet the needs of a variety of industrial applications such as automotive parts, building materials and packaging solutions.

Steel Strips Packages:

1. Oscillate Winding Packaging

Applicable Materials: stainless steel strips, carbon steel metal strips, aluminum metal strips, etc.

Features: The metal strips are wound layer by layer by oscillating back and forth, and the winding is tighter, which reduces the coils’ slippage or displacement during transportation. This can effectively save space and improve transportation efficiency, especially suitable for long-distance transportation and export.

Advantages:

- Tighter winding, reducing space occupation.

- Improve coil stability and prevent edge damage.

- Applicable to strip materials that require long roll lengths.

2. Wooden Pallet Packaging

Applicable Materials: stainless steel strips, carbon steel strips, aluminum metal strips, etc.

Features: The steel strip rolls are placed on wooden pallets and wrapped with plastic film or cardboard for easy transportation and stacking. Wooden pallets provide basic physical support and are often used for standard transportation.

3. Steel Pallet Packaging

Applicable materials: heavier materials such as stainless steel strips, carbon steel strips, and aluminum metal strips.

Features: Steel pallets are stronger than wooden pallets and suitable for heavier or high-strength steel strips. They can provide better support and pressure resistance, suitable for heavy materials.

4. Plastic Film or Waterproof Film Packaging

Applicable Materials: all types of steel strips.

Features: The outer layer is wrapped with waterproof plastic film to prevent the steel strip from getting damp and contaminated during transportation and storage. Waterproof film is a common protective material, especially suitable for export transportation.

5. Cardboard or Plastic Edge Guard

Applicable Materials: stainless steel metal strips, carbon steel strips, aluminum metal strips, etc.

Features: Add cardboard or plastic edge guards to the edges of the steel strips to prevent the edges from being damaged during handling. Especially suitable for thin materials such as stainless steel and aluminum metal strip.

6. Metal Straps and Locks Fixed

Applicable Materials: all steel strip materials.

Features: Metal straps and locks fix the metal strips to the pallet or bracket to prevent loosening or displacement during transportation. This system is suitable for long-distance transportation or coils that require high stability.

7. Rust-Proof Packaging

Applicable Materials: carbon steel strips.

Features: Carbon steel is prone to rust, so anti-rust paper or anti-rust oil film is used during packaging to prevent the material from being oxidized during transportation or storage. Suitable for carbon steel materials that need to be stored for a long time.

The Type of Strip Edge

The type of metal strip edge usually varies according to the production process, material properties, and application requirements, mainly including the following common edge types:

1. Mill Edge

Definition: Mill edge refers to the untreated edge of the steel strip, which comes directly from the hot rolling or cold rolling production line without any trimming.

Features:

- The edge is uneven and may have tiny burrs.

- The cost is low because the edge-trimming process is omitted.

- It is suitable for applications where edge accuracy is not required.

Applicable materials: carbon steel strip, stainless steel strip, aluminum metal strip, etc.

2. Slit Edge

Definition: Slit edge refers to the edge of the steel strip that has been sheared or trimmed, and the edge is relatively neat and smooth.

Features:

- The edge is precisely sheared and has no burrs.

- It is suitable for applications with high-edge quality requirements, such as products that need further processing during the manufacturing process.

- The edge shape is regular and the dimensional accuracy is high.

Applicable materials: all strip materials, especially stainless steel, and aluminum metal strips.

3. Round Edge

Definition: Round edge refers to the process of processing the edge of a metal strip into a smooth rounded shape.

Features:

- The edge is curved or rounded, without sharp edges, and is safer.

- Round edge processing can prevent scratches or damage to the edge during use.

- Commonly used in occasions requiring high safety and durability, such as automotive, aviation, or home appliance manufacturing.

Applicable materials: stainless steel strips, aluminum metal strips, copper strips, etc.

4. Beveled Edge

Definition: Beveled edge refers to processing the edge of a metal strip into an inclined angle, which is usually used in specific industrial applications.

Features:

- Chamfering can reduce stress concentration on the edge of the metal strip and avoid edge breakage or damage during use.

- Commonly used in applications requiring precision installation or welding.

Applicable materials: carbon steel, stainless steel, copper, etc.

5. Deburred Edge

Definition: Deburred edge refers to the edge of a metal strip that has been specially treated to remove edge burrs and make the edge smooth.

Features: No burrs, suitable for occasions with high safety requirements. The deburring process can prevent the edge from causing damage to other materials or personnel in subsequent operations.

Applicable materials: stainless steel strips, aluminum metal strips, carbon steel strips, etc.

6. Precision Edge

Definition: Precision edge trimming is an edge that has been processed with high precision and has extremely high dimensional accuracy and smoothness.

Features:

- The edge is very smooth and the dimensional tolerance is extremely small.

- Applicable to high-precision manufacturing industries such as electronic equipment, precision instruments, etc.

Applicable materials: Usually used in high-requirement materials such as stainless steel strips and copper strips.

Summary The types of metal strip edges mainly include burrs, trimming, rounded edges, chamfered edges, deburred edges, and precision trimming. Different edge types are suitable for different applications, from low-cost burrs to high-safety rounded edges and high-precision precision trimming. Each type has its unique advantages and applicable scenarios.

Keep In Touch For Metal Strips

Huaxiao Metal is one of China’s leading steel strip manufacturing companies, headquartered in Shanghai, China. We are committed to providing high-quality metal strip products that are widely used in the construction, infrastructure, and manufacturing industries. Contact us for a metal strip quote!