Stainless Steel Clad Plate Suppliers and Manufacturers

Are we looking for high-quality stainless steel composite plate suppliers and manufacturers? We provide high-quality stainless steel composite plates for a variety of industrial applications. Our products have excellent corrosion resistance and wear resistance. Whether you need it for construction, automotive, or other fields, we can provide customized solutions. By choosing us Huaxiao Metal, you will get competitively priced products and high-quality clad metal suppliers. Contact us now to learn more about stainless steel composite plates!

Stainless Steel Clad Plate Specification

- Thickness: Total thickness: 5-50mm (cladding material thickness: 1-10mm)

- Maximum width: 2500mm

- Maximum length: 15000mm

- Surface treatment No.1 or as per your requirements

- Base Material: ASTM A36, ASME SA516 Gr.60, 65, 70, ASME SA537 Gr.1, 2, 3, ASME SA105, ASME SA350 LF1, LF2, LF3, ASME SA387 Gr.11,12,21,22, ASME SA182 F1, 11, 12, 21, 22, ASME SA266, etc.

- Cladding Material: ASME SA240 TP304/304L, 310/310S, 316/316L, 316H, 316Ti, 317/317L, 321, 321H, 347, 347H, S31803, S32205, S32507, S32760, 405, 410S, 904L, ect.

- Composite Process: Explosive Bonding, Hot Bonding, Cold Bonding

- Manufacturing standard: ASME SA264, JIS G 3601, NB/T47002.1, YB/T4282

Looking Forward to Becoming One of Your Stainless Steel Clad Plate Suppliers

Table of Contents

Applications of Stainless Steel Clad Plate

1. Architecture and Decoration

- Facade Panels: Used in building exteriors to provide a modern look while offering excellent weather resistance and corrosion protection.

- Interior Decoration: Applied in walls, flooring, and ceilings to enhance aesthetics and durability.

- Trim and Molding: Utilized for door frames, window frames, and railings, adding a stylish and durable touch.

2. Transportation

- Automobiles: Employed in vehicle body panels and undercarriage components to provide corrosion resistance and durability.

- Marine: Used in ship hulls and decks to improve resistance to seawater corrosion.

- Rail: Applied in railway vehicles for enhanced strength and longevity.

3. Industrial Equipment

- Chemical Processing: Suitable for tanks, pipelines, and reactors due to its superior resistance to corrosive environments.

- Food Processing: Used in food machinery linings, meeting hygiene and durability standards.

- Pharmaceuticals: Employed in pharmaceutical manufacturing equipment, adhering to high cleanliness and corrosion resistance requirements.

4. Household Appliances

- Kitchen Appliances: Such as stoves, refrigerators, and dishwashers, where its durability and corrosion resistance are essential.

- Washing Machines: Used for internal drums and outer shells to enhance longevity and appearance.

5. Energy Sector

- Oil and Gas: Applied in pipelines and storage tanks, providing resistance to extreme environmental conditions.

- Renewable Energy: Used in solar panel frames and wind turbine components to ensure durability and efficiency.

6. Public Facilities

- Subways and Light Rail: Used in stations and train interiors for durability and visual appeal.

- Airports and Train Stations: Applied in waiting areas, corridors, and other high-traffic areas for decoration and protection.

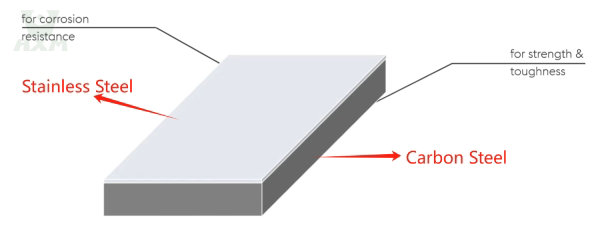

Features of Stainless Steel Clad Plate

Strong Corrosion Resistance: The stainless steel layer prevents corrosion and is suitable for harsh environments.

High Strength: Combined with the high strength of the base material, it is wear-resistant.

Lightweight: Composited with lightweight base materials such as aluminum alloy to reduce weight.

Beautiful: The surface can be treated in various ways, suitable for decorative applications.

Economical and Practical: Combines economical base materials and durable stainless steel, which is cost-effective.

High Temperature Resistance: Suitable for high-temperature environments.

Easy to Process: It can be processed by cutting, welding and other methods.

Looking Forward to Becoming One of Your Stainless Steel Clad Plate Suppliers

Other Types of Stainless Steel Clad Plate

According to the composite process of stainless steel clad plates, we divide them into three categories: hot composite plates, cold composite plates, and explosive composite plates.

Hot Bonding Stainless Steel Clad Plate

The stainless steel layer and the base material (such as carbon steel, aluminum alloy, etc.) are combined together by hot pressing equipment at high temperatures. Usually the temperature is above 1000°C, and the heat and pressure form a strong bond between the metal layers.

Looking Forward to Becoming One of Your Stainless Steel Clad Plate Distributors

Cold Bonding Stainless Steel Clad Plate

At room temperature or lower temperature, the stainless steel layer is bonded to the substrate by mechanical pressure or adhesive. This method does not require heating and is suitable for temperature-sensitive materials.

Explosive Bonding Stainless Steel Clad Plate

The high-pressure shock wave generated by the explosion is used to bond the stainless steel layer and the substrate together at extremely high speeds. The method is carried out in a controlled environment.

Looking Forward to Becoming One of Your Stainless Steel Clad Plate Manufacturers

How to Make Stainless Steel Clad Plate?

1. Raw Material Preparation

Stainless steel sheet: Choose high-quality stainless steel as the surface layer, commonly used materials are 304, 316, etc.

Substrate: The substrate is usually carbon steel, aluminum alloy, or other metal materials, and the selection depends on the use requirements of the product.

2. Surface Treatment

The stainless steel sheet is cleaned, degreased and surface treated to ensure good bonding with the substrate. Surface treatment methods include pickling, sandblasting, etc.

3. Composite Process

Hot Bonding: The stainless steel sheet and the substrate are combined by heating and pressure, usually using hot pressing or hot rolling. At high temperatures, the surfaces of the stainless steel and the substrate will fuse to form a strong composite layer.

Cold Bonding: The stainless steel sheet and the substrate are combined by cold pressing or adhesive. This method is suitable for lower temperatures or special requirements for the substrate material.

Explosive Bonding: The explosive bonding process uses the high-pressure shock wave generated by the explosion to cause two or more metal materials to collide strongly at an extremely high speed, thereby achieving the bonding between the materials. The explosive shock wave can compress and bond the metal sheets together in a short time.

4. Pressing and Cooling

During the composite process, the sheet is pressed to ensure that the surface layer is fully bonded to the substrate. After that, the sheet needs to be cooled to room temperature to solidify the composite layer.

5. Cutting and Processing

According to customer needs, the composite panels are cut, punched, slotted, and other processing is carried out to meet specific size and shape requirements. Cutting can be done using laser cutting, shearing machines, or other processing equipment.

6. Surface Treatment and Inspection

Surface treatment: Further processing of the composite panel surface may be required, such as polishing, spraying, or coating, to enhance its corrosion resistance and aesthetics.

Quality inspection: The composite panel is subjected to strict quality inspection, including appearance inspection, thickness test, adhesion test, etc., to ensure that it meets quality standards and customer requirements.

7. Packaging and Transportation

After production, the stainless steel composite panel will be cleaned and packaged. Packaging materials usually include plastic film, cardboard, and wooden pallets to prevent damage during transportation.

Looking Forward to Becoming One of Your Stainless Steel Clad Plate Manufacturers

Why Choose Huaxiao As Your Stainless Steel Clad Plate Suppliers?

Superior Quality Materials: Huaxiao uses only premium-grade stainless steel and high-quality base materials, ensuring exceptional durability, strength, and corrosion resistance in every clad plate we produce.

Advanced Manufacturing Technology: We employ cutting-edge technology and state-of-the-art machinery in our manufacturing processes. This ensures precise bonding and optimal performance, meeting the highest industry standards.

Custom Solutions: Our team provides tailored solutions to meet your specific needs. From custom sizes and thicknesses to unique surface finishes, we work closely with you to deliver products that fit your exact requirements.

Experienced Professionals: With years of experience in the industry, our skilled professionals ensure that every product is crafted with expertise and attention to detail, guaranteeing superior quality and reliability.

Competitive Pricing: At Huaxiao, we offer cost-effective solutions without compromising on quality. Our efficient production processes and bulk purchasing power allow us to provide competitive pricing to our customers.

Rigorous Quality Control: We adhere to stringent quality control procedures at every stage of production. Our comprehensive testing and inspection processes ensure that every stainless steel clad plate meets the highest standards before delivery.

Excellent Customer Service: Our dedicated customer service team is always ready to assist you with inquiries, provide technical support, and ensure a smooth and satisfactory purchasing experience.

On-Time Delivery: We understand the importance of timely delivery in your projects. Huaxiao is committed to on-time delivery, ensuring that you receive your products when you need them.

Choose Huaxiao as your stainless steel clad plate supplier to experience unmatched quality, reliability, and service. Let us help you achieve your project goals with our premium products and exceptional support.

Looking Forward to Becoming One of Your Stainless Steel Clad Sheet Distributors

Contact Shanghai Huaxiao's Stainless Steel Clad Plate Supplier Now