Explosive Bonding, Hot Bonding and Cold Bonding are three different metal bonding technologies, each with its own unique process principles, advantages and application scenarios. The following are the main differences between them:

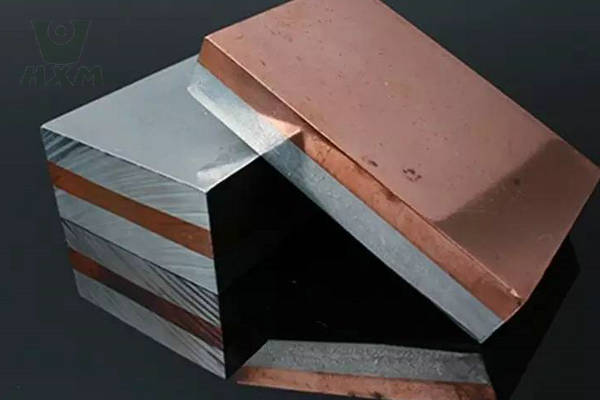

Clad Steel

Process Principle

Explosive Bonding

Principle: Use the high-pressure shock wave generated by the explosion to press two or more metal materials together at an extremely high speed to achieve a bond between metals. The shock wave causes the metal plates to form a strong composite layer in an instant.

Features: Very high pressing speed and strength.

Hot Bonding

Principle: Combine the stainless steel layer and the substrate (such as carbon steel or aluminum) through hot pressing equipment at high temperature. Usually it needs to be carried out in a high temperature environment, and the temperature can exceed 1000°C.

Features: High temperature causes plastic deformation of the metal surface, thereby achieving a strong bond.

Cold Bonding

Principle: At room temperature or lower temperature, the stainless steel layer is bonded to the substrate by mechanical pressing or adhesive. No heating is required, and bonding is performed using adhesive or mechanical pressure.

Features: Simple operation, suitable for temperature-sensitive materials.

Advantages and Disadvantages

Explosive Bonding

Advantages: It can achieve extremely high-strength metal bonding, is suitable for large-area bonding, and can handle the bonding of different metals.

Disadvantages: High production cost, strict safety measures, and control are required, and there are certain restrictions on applicable materials and shapes.

Hot Bonding

Advantages: It can achieve good metal bonding at high temperatures, is suitable for applications with high strength requirements, and has a stable process.

Disadvantages: It requires heating equipment and a high-temperature environment, high energy consumption, and a complex production process.

Cold Bonding

Advantages: It is easy to operate, suitable for temperature-sensitive materials, and has a low production cost.

Disadvantages: The bonding strength is usually not as good as hot bonding and explosive bonding, and depends on the quality of the adhesive.

Application Fields

Explosive Bonding

Application: Applicable to aerospace, defense, chemical equipment shipbuilding, etc., where high-strength and high-performance materials are required.

Hot Bonding

Application: Widely used in construction, transportation, and industrial equipment, suitable for applications requiring high corrosion resistance and strength.

Cold Bonding

Application: Applicable to some low-temperature environments or temperature-sensitive materials, often used in electronic products, building decoration and some industrial applications.

Cost and Process Complexity

Explosive Bonding: high cost, complex process, involving safety and environmental control.

Hot Bonding: high-cost, but relatively mature process, suitable for large-scale production.

Cold Bonding: low cost, relatively simple process, suitable for small-scale production and special materials.

Each bonding process has its specific advantages and application scenarios. The choice of which process depends on the specific project requirements, budget and material properties.