Incoloy is a family of superalloys primarily composed of nickel and iron, with smaller amounts of chromium and other elements. Renowned for their excellent resistance to oxidation, corrosion, and high temperatures, Incoloy alloys are widely used in demanding industrial applications.

What are Incoloy Metals and Alloys?

Incoloy metal alloy is a general term for a series of high-iron high-temperature alloys. Depending on the ratio of nickel, chromium and iron, Incoloy alloy can be nickel-iron-chromium alloy, iron-nickel-chromium alloy or iron-chromium-nickel alloy.

In the context of the development of Incoloy alloy, nickel is a very scarce strategic metal. Therefore, people hope to have an alloy with a lower nickel content but equally resistant to high-temperature corrosion. And Incoloy is an alloy that meets the demand. It uses a large amount of iron instead of nickel. Although its corrosion resistance is not as good as Inconel alloy, it is sufficient in many cases and costs less.

In short, Incoloy alloy is a nickel-saving Inconel alloy. It is cheaper than Inconel.

Incoloy Metals and Alloys Grades

Different grades of Incoloy alloys are tailored to meet specific industrial needs. The grades are categorized into three main types:

Incoloy 800 Series

Applications: Heat exchangers, nuclear power plants, and petrochemical furnaces.

Features: Excellent resistance to high temperatures and carburization.

Notable Grades: Incoloy 800, 800H, 800HT

Incoloy 825

Applications: Chemical processing, pollution control equipment, and marine environments.

Features: Exceptional resistance to sulfuric and phosphoric acids.

Incoloy 925

Applications: Oil and gas drilling, marine engineering.

Features: High strength combined with superior corrosion resistance

Incoloy Alloys Data Sheet

Incoloy Alloys Chemical Compositions

| Element | Incoloy 800 | Incoloy 825 | Incoloy 925 |

|---|---|---|---|

| Ni | 30-35% | 38-46% | 42-46% |

| Cr | 19-23% | 19.5-23.5% | 19.5-23.5% |

| Fe | Balance | Balance | Balance |

| Mo | – | 2.5-3.5% | 2.5-3.5% |

| Cu | – | 1.5-3.0% | 1.5-3.0% |

| C | ≤0.1% | ≤0.05% | ≤0.03% |

The Mechanical Properties of Incoloy

| Property | Incoloy 800 | Incoloy 825 | Incoloy 925 |

|---|---|---|---|

| Tensile Strength (MPa) | ≥450 | ≥550 | ≥650 |

| Yield Strength (MPa) | ≥170 | ≥220 | ≥300 |

| Elongation (%) | ≥30 | ≥30 | ≥25 |

| Hardness (HB) | ≤200 | ≤200 | ≤220 |

The Physical Properties of Incoloy

| Property | Incoloy 800 | Incoloy 825 | Incoloy 925 |

|---|---|---|---|

| Density (g/cm³) | 7.94 | 8.14 | 8.14 |

| Melting Point (°C) | 1357-1385 | 1350-1400 | 1350-1400 |

| Thermal Conductivity (W/m·K) | 11.2 | 10.8 | 10.8 |

| Electrical Resistivity (µΩ·m) | 1.05 | 1.07 | 1.08 |

Characteristics of Incoloy Alloys

High-Temperature Resistance: Incoloy metals maintain their strength and stability even at elevated temperatures, making them ideal for heat exchangers and furnace components.

Corrosion Resistance: The chromium and nickel content provides excellent protection against oxidation and corrosive environments, such as seawater and acidic chemicals.

Versatility: Incoloy alloys can be fabricated into various forms, including sheets, plates, bars, and wires, to suit different industrial needs.

Special Properties of Incoloy Alloys

Corrosion Resistance of Incoloy Alloys

| Corrosive Medium | Incoloy 800 | Incoloy 825 | Incoloy 925 |

|---|---|---|---|

| Oxidation Resistance | Excellent | Good | Good |

| Sulfuric Acid Resistance | Limited | Excellent | Excellent |

| Chloride Stress Corrosion Cracking | Moderate | Excellent | Excellent |

| Seawater Resistance | Limited | Excellent | Excellent |

Machinability of Incoloy Alloys

| Performance | Details |

|---|---|

| Cutting | Requires carbide tools due to material hardness. |

| Forming | Good ductility allows for cold and hot forming. |

| Surface Finish | Excellent polishability for industrial and aesthetic uses. |

Weldability of Incoloy Alloys

| Welding Process | Suitability |

|---|---|

| Gas Tungsten Arc Welding (GTAW) | Highly suitable for thin sections and precision welding. |

| Shielded Metal Arc Welding (SMAW) | Commonly used for thicker sections. |

| Pre- and Post-Weld Heat Treatment | Recommended for reducing residual stress. |

Heat Treatment of Incoloy Alloys

| Heat Treatment | Effect on Properties |

|---|---|

| Annealing | Enhances ductility and removes residual stresses. |

| Aging Treatment | Increases strength and hardness for Incoloy 925. |

| Stress Relief | Minimizes distortion during machining or welding. |

Additional Features

| Performance Aspect | Description |

|---|---|

| Thermal Fatigue Resistance | High resistance to thermal cycling. |

| Oxidation at Elevated Temperatures | Maintains protective oxide layer up to 1000°C. |

| Magnetic Properties | Non-magnetic under normal conditions. |

Benefits of Incoloy Alloys

Superior performance in harsh environments.

Long lifespan with minimal maintenance.

Availability in multiple grades and forms to meet diverse requirements.

Interested in learning more about Incoloy alloys? Contact us for detailed specifications and pricing!

Applications for Incoloy Alloys

Incoloy alloys are highly versatile and find applications in several industries:

Aerospace: Components subjected to high stress and temperatures, such as jet engines.

Petrochemical Industry: Heat exchangers, process piping, and reactors.

Marine Industry: Corrosion-resistant parts for offshore platforms and subsea operations.

Power Generation: Turbine blades, nuclear reactor components.

In Conclusion

Incoloy metals and alloys are ideal for industries that demand reliable performance in demanding environments. With their outstanding resistance to high temperatures, corrosion, and versatility, they continue to be the material of choice for critical applications around the world.

Looking for high-quality Incoloy alloys? Contact us today to discuss your requirements and request a quote!

Recommended Articles

Incoloy vs Copper

Incoloy vs copper are widely used materials across various industries, each with unique properties and applications. Choosing the right material can significantly impact the efficiency

Incoloy 800 vs 825 Alloy

Incoloy 800 vs 825 are two widely used nickel-iron-chromium alloys that are known for their excellent corrosion resistance, mechanical strength, and suitability for high-temperature environments.

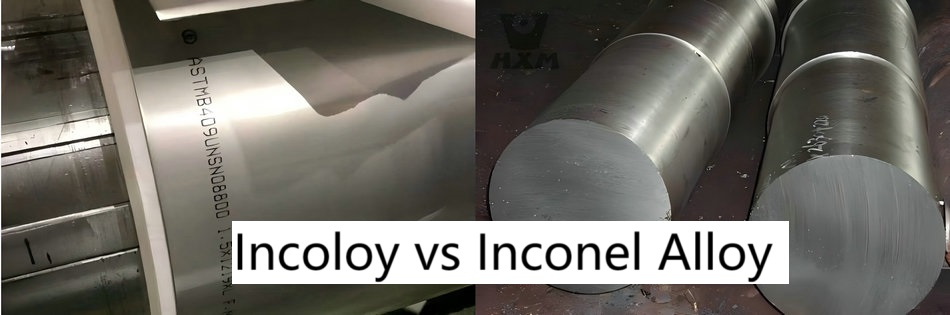

Incoloy vs Inconel Alloy

Incoloy vs Inconel are two prominent superalloys known for their excellent performance in demanding environments. Both materials are widely used across various industries, but they

Incoloy Alloy

Incoloy Alloy Supplier and Manufacturer From China Incoloy alloys are a class of corrosion-resistant and high-temperature alloys widely used in petrochemical, chemical processing, seawater treatment,