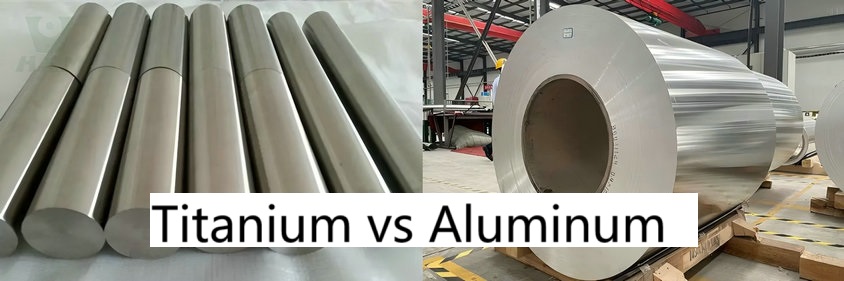

When choosing between titanium vs aluminum, it is important to understand the differences in weight, strength, corrosion resistance, and applications. Both metals are widely used in industries such as aerospace, automotive, and construction, but each has unique advantages and limitations. In this blog, we will compare titanium and aluminum from various aspects to help you decide which one is best for your needs.

What Is Titanium Alloy?

Titanium Alloy

Titanium Alloy Supplier and Manufacturer From China Huaxiao Metal is a China and Asia wide supplier of metal and titanium raw materials to the industrial,

Titanium alloy is an alloy material formed by the combination of titanium and aluminum, molybdenum, vanadium and other elements. It has high strength, low density, excellent corrosion resistance and high temperature resistance. Due to these characteristics, titanium alloys are widely used in aerospace, medical, military, chemical and marine engineering. Common titanium alloys include α, β and α+β types, among which Ti-6Al-4V (6% aluminum, 4% vanadium) is one of the most widely used titanium alloys.

If you want to know more about the specific classification and application of aluminum alloys or titanium alloys, please contact us!

What Is Aluminum Alloy?

Aluminum alloys are alloy materials formed by mixing aluminum with other metals (such as copper, magnesium, silicon, zinc, etc.) or non-metallic elements. Compared with pure aluminum, aluminum alloys have higher strength, hardness and corrosion resistance while still maintaining a lighter weight. Aluminum alloys are widely used in industries such as aerospace, automobiles, construction, and electronic equipment. Common aluminum alloy categories include 2xxx, 5xxx, 6xxx, and 7xxx series, of which 6061 and 7075 are the most common high-performance aluminum alloys.

Aluminium Metal

Aluminium Metal Suppliers | Manufacturers Trusted aluminum solutions for your business needs Reliable delivery of high-quality aluminum sheet/coil/strip/tube/wire/bar Get A Quote Looking for a reliable

Titanium vs Aluminum: Key Differences

Aluminium vs Titanium – Material Property Comparison

Below is a detailed comparison of aluminium alloys and titanium alloys based on Material, Condition, Process, Tensile Strength, Elongation, and Hardness.

| Material | Condition | Process | Tensile Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| 6061 Aluminium | T6 (Heat Treated) | Extrusion, Rolling, Forging | 310–350 | 8–12 | 95–105 |

| 7075 Aluminium | T6 (Heat Treated) | Extrusion, Rolling, Forging | 560–570 | 7–10 | 150–160 |

| 5052 Aluminium | H32 (Strain Hardened) | Rolling, Stamping | 230–260 | 10–12 | 60–70 |

| 2024 Aluminium | T3 (Solution Heat Treated) | Extrusion, Rolling | 430–500 | 10–15 | 120–140 |

| Ti-6Al-4V (Grade 5 Titanium) | Annealed | Forging, Machining, 3D Printing | 900–1100 | 10–15 | 320–380 |

| Grade 2 Titanium (Pure Ti) | Annealed | Rolling, Welding | 340–410 | 20–30 | 150–200 |

| Ti-3Al-2.5V (Grade 9 Titanium) | Annealed | Forging, Machining | 620–700 | 15–25 | 250–300 |

| Ti-6Al-2Sn-4Zr-6Mo | Annealed | Forging, Heat Treatment | 1050–1200 | 10–15 | 350–400 |

Weight Comparison: Is Titanium Lighter Than Aluminum?

One of the most common questions is, Is titanium lighter than aluminum? The answer is no. Titanium is actually heavier than aluminum. The density of titanium is about 4.5 g/cm³, while aluminum has a density of 2.7 g/cm³. This means that aluminum is roughly 40% lighter than titanium, making it a preferred choice for applications where weight reduction is critical.

Titanium vs Aluminum: Strength and Durability

Although aluminum is lighter, titanium is significantly stronger. Titanium has a higher tensile strength (approximately 434 MPa for pure titanium and up to 1,100 MPa for titanium alloys), whereas aluminum alloys typically have a tensile strength between 200 MPa and 600 MPa. This makes titanium a better option for applications requiring extreme durability, such as aircraft frames and medical implants.

Titanium vs Aluminum: Corrosion Resistance

Both titanium and aluminum have excellent corrosion resistance, but titanium performs better in harsh environments. Titanium forms a strong, protective oxide layer that resists corrosion even in saltwater and acidic conditions. Aluminum, while also resistant to corrosion, is more prone to oxidation and pitting, especially in marine or highly acidic environments.

Titanium vs Aluminum: Cost Comparison

Titanium is much more expensive than aluminum due to its complex extraction and manufacturing processes. Aluminum is more abundant and easier to process, making it the more cost-effective option for general applications. If budget constraints are a concern, aluminum is the better choice.

Titanium vs Aluminum: Machinability and Fabrication

Aluminum is easier to machine, cut, and weld compared to titanium. Titanium is notorious for being difficult to machine due to its hardness and low thermal conductivity, which can lead to tool wear and overheating during processing. Aluminum, on the other hand, is much more malleable and can be shaped with less effort.

Applications of Titanium vs Aluminum

Feature | Titanium | Aluminum |

|---|---|---|

Weight | Heavier than aluminum | Lightweight |

Strength | Stronger and more durable | Moderate strength |

Corrosion Resistance | Excellent (even in extreme environments) | Good but susceptible to pitting |

Cost | Expensive | More affordable |

Machinability | Difficult to machine | Easy to machine and fabricate |

When to Choose Titanium

Aerospace components requiring high strength and corrosion resistance.

Medical implants like bone screws and hip replacements.

High-performance automotive parts in racing or military vehicles.

Marine applications where exposure to saltwater is constant.

When to Choose Aluminum

Aircraft fuselage and body panels where weight is crucial.

Consumer electronics like laptops and smartphones.

Automotive parts in standard vehicles for fuel efficiency.

Construction materials for buildings and infrastructure.

How to Tell Titanium vs Aluminum?

If you need to differentiate between titanium and aluminum, here are some methods:

Weight Test: Titanium is heavier than aluminum. If you have two similar-sized metal pieces, the heavier one is likely titanium.

Magnet Test: Both metals are non-magnetic, so this test won’t work for identification.

Color and Surface Appearance: Titanium typically has a darker gray color, while aluminum has a shinier silver appearance.

Spark Test: When ground against a wheel, aluminum produces little to no sparks, while titanium produces bright white sparks.

Scratch Test: Titanium is much harder than aluminum and will resist scratches better.

In Conclusion:

Choosing between titanium and aluminum depends on your specific needs. If you require a lightweight, cost-effective material, aluminum is an excellent choice. However, if strength, durability, and corrosion resistance are your top priorities, titanium is the superior option despite its higher cost. Understanding these differences can help you make informed decisions for your applications.

Looking for high-quality titanium or aluminum materials? Contact us today for expert guidance and competitive pricing!

Huaxiao Special Alloy Steel Products

Incoloy Alloy

Incoloy Alloy Supplier and Manufacturer From China Incoloy alloys are a class of corrosion-resistant and high-temperature alloys widely used in petrochemical, chemical processing, seawater treatment,

Monel Alloy

Monel Alloy Supplier and Manufacturer From China Monel Alloy is a high-performance alloy composed of nickel and copper, known for its excellent corrosion resistance and

Inconel Alloy

Inconel Alloy Supplier and Manufacturer From China We specialize in providing high-quality Inconel alloys to meet the needs of various industrial applications. Inconel alloy is

Titanium Alloy

Titanium Alloy Supplier and Manufacturer From China Huaxiao Metal is a China and Asia wide supplier of metal and titanium raw materials to the industrial,

Precision Alloy

Precision Alloy Supplier and Manufacturer From China As a leading supplier of precision alloy steel, we provide high-quality alloy steel materials, which are widely used

Hastelloy Alloy

Hastelloy Alloy Supplier and Manufacturer From China We provide high-performance Hastelloy Alloy materials designed to cope with corrosion, thermal stress, and high-temperature requirements in extreme

High Temperature Alloy

High Temperature Alloy Supplier and Manufacturer From China As a leading supplier of high temperature alloys, we are committed to providing customers with high quality

Precipitation Hardening Stainless Steel

Precipitation Hardening Stainless Steel Supplier and Manufacturer From China Precipitation hardening stainless steel is known for its excellent high strength and corrosion resistance and is