Among the many titanium alloy products, Grade 2 vs Grade 5 Titanium are the two most common and widely used titanium grades. As a professional metal material supplier, Huaxiao Metal provides customers with high-quality titanium alloy products. To help customers better understand the performance and uses of different grades of titanium, we have specially compiled this technical blog article to deeply analyze the differences between Grade 2 vs Grade 5 Titanium to help you make more informed purchasing decisions.

What is Grade 2 Titanium?

Grade 2 titanium is commercially pure titanium, and its main component is titanium (Ti) with a content of not less than 98.9%. Although it contains trace amounts of impurity elements such as iron (Fe), oxygen (O), and carbon (C), it is still a low-alloy structure as a whole, with excellent corrosion resistance and ductility.

Main features of Grade 2 Titanium:

- Excellent corrosion resistance: especially in chloride environments, seawater, and acidic solutions.

- Good ductility and formability: suitable for cold working, stamping, stretching, and other processing techniques.

- Medium strength: The tensile strength is usually around 345 MPa.

- Lightweight characteristics: low density, suitable for applications that require lightweight.

- High biocompatibility: suitable for medical devices and biological implants.

What is Grade 5 Titanium?

Grade 5 Titanium is the most famous titanium alloy grade. Its standard grade is Ti-6Al-4V, which contains 6% aluminum (Al) and 4% vanadium (V). This is a reinforced alloy material that far exceeds pure titanium in strength, hardness, and heat resistance. It is widely used in aerospace, high-end manufacturing, and precision equipment.

Main features of Grade 5 Titanium:

- Extremely high strength: The tensile strength is as high as 900-1100 MPa, which is almost 3 times that of Grade 2 Titanium.

- Excellent heat resistance: It can maintain good mechanical properties at temperatures above 400°C.

- Good corrosion resistance: Although slightly inferior to Grade 2 Titanium, it still performs well in most industrial environments.

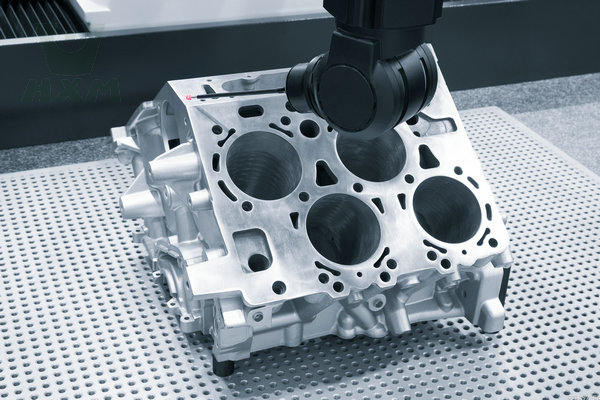

- Higher processing difficulty: Special tools and techniques are required for efficient processing.

- Higher cost: Due to its alloying elements and improved properties, the price is usually higher than commercial pure titanium.

Difference Between Grade 2 vs Grade 5 Titanium

Chemical Composition: Grade 2 vs Grade 5 Titanium

| Composition Elements | Grade 2 | Grade 5 / Ti-6Al-4V |

|---|---|---|

| Ti | ≥ 98.9% | Bal |

| O | ≤ 0.25% | ≤ 0.20% |

| Fe | ≤ 0.30% | ≤ 0.40% |

| C | ≤ 0.08% | ≤ 0.08% |

| N | ≤ 0.03% | ≤ 0.05% |

| H | ≤ 0.015% | ≤ 0.015% |

| Al | no | 5.5% – 6.75% |

| V | no | 3.5% – 4.5% |

Grade 2 titanium is commercially pure titanium, while grade 5 titanium is a titanium alloy with added aluminum and vanadium elements to improve strength and thermal stability.

Physical Properties: Grade 2 vs Grade 5 Titanium

Properties | Grade 2 | Grade 5 |

|---|---|---|

| Density | 4.51 g/cm³ | 4.43 g/cm³ |

| Melting Point | 1665°C | 1660°C |

| Thermal Conductivity | 16.0 W/m·K | 6.7 W/m·K |

| Conductivity | 1.8% IACS | 1.2% IACS |

| Specific Heat | 0.52 J/g·K | 0.526 J/g·K |

| Elastic Modulus (E) | 103 GPa | 113.8 GPa |

| Coefficient of Thermal Expansion | 8.6×10⁻⁶ /K | 8.6×10⁻⁶ /K |

Although the melting points of the two are similar, grade 5 titanium has a lower thermal conductivity and is more suitable for high-temperature and high-strength applications.

Mechanical Properties: Grade 2 vs Grade 5 Titanium

Properties | Grade 2 Ti | Grade 5 Ti |

|---|---|---|

| Tensile Strength (MPa) | ≥ 345 | ≥ 895 |

| Yield Strength (MPa) | ≥ 275 | ≥ 828 |

| Elongation (%) | ≥ 20 | ≥ 10 |

| Hardness(HRB) | 70–80 | 36–44(HRC) |

| Fatigue Strength (MPa) | ~240 | ~510 |

Grade 5 titanium is far ahead in strength and is more suitable for withstanding mechanical shock and high-load environments, while grade 2 titanium excels in processability and ductility.

Other Properties: Grade 2 vs Grade 5 Titanium

Properties | Grade 2 Titanium | Grade 5 Titanium |

|---|---|---|

| Corrosion Resistance | Excellent | Good |

| Weldability | Excellent | Average |

| Machinability | Very Good | Requires special tools and experience |

| Biocompatibility | Very high (commonly used in medical implants) | High (can also be used in medical components) |

| Cost | Lower | Significantly higher |

| Common Application | Chemical, medical, offshore | Aerospace, military, precision manufacturing |

If your project focuses on corrosion resistance, cost control, and easy processing, it is recommended to use grade 2 titanium; if the project emphasizes strength, heat resistance, and structural stability, grade 5 titanium is a better choice.

Typical Application of Grade 2 vs Grade 5 Titanium

Application of Grade 2 Titanium:

- Chemical equipment: reactors, heat exchangers, piping systems, suitable for highly corrosive media.

- Marine engineering: hull components, diving equipment, to resist seawater corrosion.

- Medical devices: dentures, surgical instruments, human implants.

- Environmental protection equipment: electroplating, electrolysis, electrode materials.

- Daily necessities: titanium cups, titanium tableware, titanium jewelry.

Application of Grade 5 Titanium:

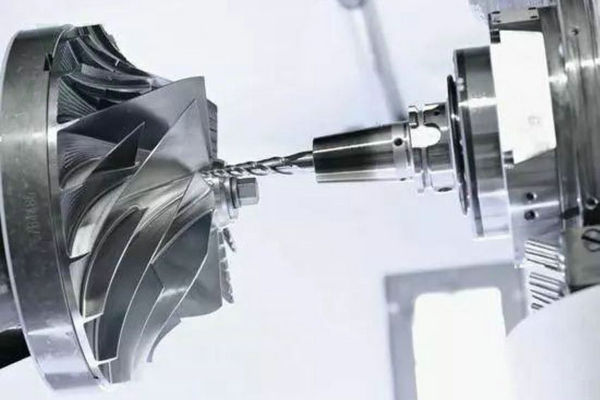

- Aerospace industry: aircraft structural parts, engine parts, fasteners.

- Racing cars and high-performance machinery: suspension systems, engine components, brake systems.

- Precision manufacturing: 3D printed titanium parts, medical implants, aerospace components.

- Military products: missile structures, ship structures.

Grade 2 and grade 5 titanium each have their own advantages and are suitable for different industrial applications. Understanding their performance differences will help you select and purchase materials more rationally. As an experienced metal material supplier, Huaxiao Metal not only provides you with high-quality titanium alloy products, but also provides professional advice and after-sales support for your project.

Welcome to contact us for the latest titanium alloy prices and inventory!

Which One Should You Choose? Grade 2 vs Grade 5 Titanium

In the actual procurement process, the appropriate titanium grade should be selected according to your application requirements:

If you do not have high requirements for material strength, but attach importance to corrosion resistance and processability, it is recommended to choose grade 2 titanium.

If you have extremely high requirements for material strength and high temperature resistance, and apply it to high-end manufacturing industries, it is recommended to use grade 5 titanium.

If you are not sure which grade of titanium to choose, please consult Huaxiao Metal’s technical team, we will provide you with professional advice and customized services.

Huaxiao Metal's Titanium Alloy Product Advantages

As a professional metal material supplier in China, Huaxiao Metal provides titanium materials of multiple grades, including grade 2, grade 5, grade 7, grade 9, etc., and the product forms include titanium plates, titanium rods, titanium tubes, titanium wires, etc. Our advantages include:

✅ Multiple specifications in stock, fast delivery

✅ Provide original material certificate (MTC)

✅ Support processing and customization services according to drawings

✅ Export packaging meets international transportation standards

✅ Can be exported to Europe, America, Southeast Asia, the Middle East and other countries and regions

We always adhere to the concept of “quality first, service first”, and are committed to becoming a trusted titanium alloy material supplier for global customers.