What Steel Has High Hardness and Good Toughness?

This question can be roughly divided into three situations to answer: First, the hardness HRC of mold steel LG with good toughness is between 50-58. The hardness of LG mold steel is HRC56-58, and its toughness is 8-9 times that of DC53. The ability of steel to resist fracture under impact is called toughness. Simple […]

The Characteristics of the Welding Process of High Carbon Steel

The Characteristics of The Welding Process of High Carbon steel Preheating and post-heat treatment: Preheating and post-heat treatment are usually required to reduce the tendency of welding cracks. Preheating temperature: Generally between 150°C and 350°C, depending on the type of steel and thickness. Post-heat treatment: Slow cooling after welding and tempering treatment to reduce welding […]

What Steel Is EM2?

What Steel Is EM2? EM2 high-speed steel is a general-purpose tool steel widely used in rolling mills and other fields. Its chemical composition includes carbon, chromium, molybdenum, tungsten, vanadium, and other elements, and the content of these elements has an important influence on its performance. EM2 is a traditional Swedish high-speed tool steel with high […]

What Is Powder Steel?

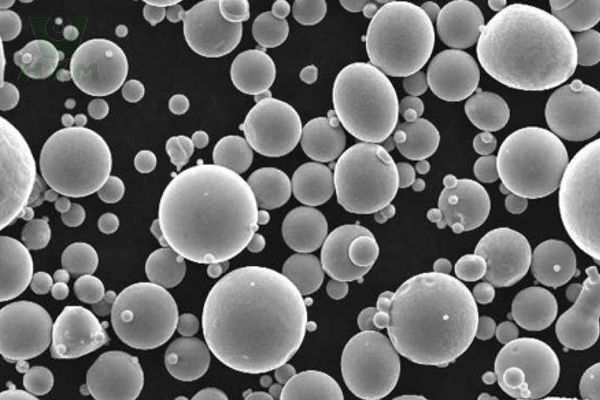

Powder steel powder metallurgy is a metallurgical method using metal powder as raw material. It is a special process that uses a certain amount of metal powder to synthesize, mix, sinter, and other processes to smelt a new type of metal material that can be used to manufacture tools and accessories. Powder forging refers to […]

Carbon Structural Steel Grades

Carbon Structural Steel Grades Carbon structural steel can be divided into five grades: Q19, Q21, Q23, Q25, Q5, and Q27, with a carbon content range of 0.6-38%. Each grade is divided into several grades according to the different content of harmful impurities such as sulfur and phosphorus. The representation methods of AISI and SAE (American […]

Comparison of Tungsten Steel and High Speed Steel

What is Tungsten Steel? Tungsten steel, also known as tool steel, refers to a type of steel alloy with tungsten as the main alloying element. Tungsten steel is highly regarded for its excellent hardness, high temperature strength and wear resistance, making it an ideal choice for a variety of industrial and cutting applications. Get A […]

Comparison of High Speed Steel and High Carbon Steel

What is High Speed Steel? High-speed steel is a subset of tool steel, so named for its ability to cut through materials at higher speeds than carbon steel. It is known for retaining hardness and strength at high temperatures, making it ideal for cutting tools and machining operations. Get A Quote What is High Carbon […]

Comparison of Mold Steel and Carbon Steel

What is Mold Steel? Mold steel refers to a specialized type of steel designed for use in making molds and tooling for industrial processes such as injection molding, die casting, and extrusion. What is Carbon Steel? Carbon steel is a versatile and widely used category of steel that primarily consists of iron and carbon, with […]

What is the Material of C3-80?

What is the Material of C3-80 C3-80 product material belongs to martensitic stainless steel, tensile strength of 800 Nm / mm3, C3-80 just means mechanical properties. This product involves raw materials, forging mode (red forging or cold heading), cooling mode (oil cooling, water cooling, air cooling), cleaning mode, heat treatment mode (vacuum heat treatment, box […]

What is SUS Material?

What is SUS Material? SUS is the Japanese standard for stainless steel materials. The Japanese stainless steel material standard is expressed as sus plus a number. Different numbers represent different types of stainless steel. The first letter s in the period indicates the meaning of steel, the second letter indicates the meaning of use, and […]