Selecting the right type of steel is critical to ensuring product quality, durability, and cost-effectiveness. Two common types of steel used in a variety of applications are 1008 vs 1018 steel. This blog post dives into the specifics of these two steels, compares their properties, and provides insights to help you make an informed decision for your manufacturing needs.

1018 Steel

AISI 1018 Steel Suppliers and Manufacturer 1018 Carbon Steel Available Products Round Bar Flat Bar Square Bar Hexagon Bar Plate Coil Tube and More Please

1008 Steel

1008 Steel – Premium Low Carbon Steel from Huaxiao Metal 1008 steel is a common low-carbon steel with excellent weldability and formability, making it ideal

Need reliable 1008 or 1018 steel materials? Contact Huaxiao Metal for sourcing and custom cutting services.

1008 vs 1018 Steel: What’s the Difference?

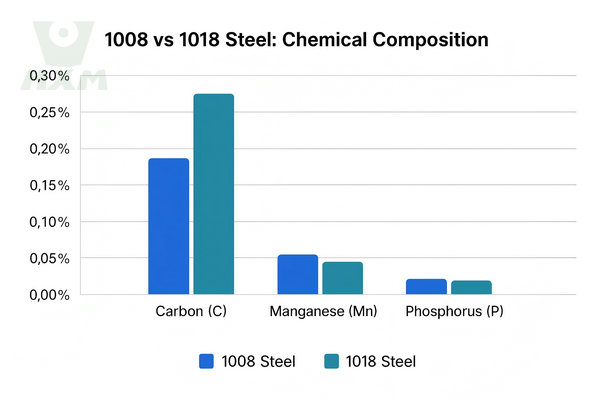

Chemical Composition of 1008 vs 1018 Steel:

The main difference between 1008 and 1018 steels is their carbon content, a difference that affects their mechanical properties and applications.

Element | 1008 Steel | 1018 Steel |

C | 0.08%max | 0.15-0.20% |

Mn | 0.30-0.50% | 0.60-0.90% |

P | 0.04%max | 0.04%max |

S | 0.05%max | 0.05%max |

Fe | Balance | Balance |

Comparison of Mechanical Properties: 1008 vs 1018 Steel

Understanding the mechanical properties of 1008 and 1018 steel is critical to choosing the right material for your application. This comparison will help you choose the right carbon steel for your specific needs!

| Property | 1008 Steel | 1018 Steel |

|---|---|---|

| Carbon Content | 0.08-0.10% | 0.14-0.20% |

| Tensile Strength | 340-440 MPa | 440-560 MPa |

| Yield Strength | 170-300 MPa | 370 MPa |

| Elongation | Approximately 25-35% | Approximately 15-25% |

| Hardness (Brinell) | 95-125 HB | 126-179 HB |

| Machinability | Good | Good |

| Weldability | Excellent | Excellent |

| Formability | Excellent | Good |

| Applications | Cold-headed fasteners, wire, and deep drawing applications | Shafts, pins, gears, and machinery parts |

Both steels offer good machinability and weldability, with specific properties making them suitable for different applications.

Comparison of Physical Properties: 1008 vs 1018 Steel

Property | 1008 Steel | 1018 Steel |

|---|---|---|

Density | 7.87 g/cm³ | 7.87 g/cm³ |

Thermal Conductivity | 51.9 W/m·K | 51.9 W/m·K |

Specific Heat Capacity | 486 J/kg·K | 486 J/kg·K |

Electrical Resistivity | 0.0000159 Ω·cm | 0.0000159 Ω·cm |

Modulus of Elasticity | 200 GPa | 200 GPa |

Poisson’s Ratio | 0.29 | 0.29 |

Melting Point | 1426-1538°C | 1426-1538°C |

The physical properties of 1008 and 1018 steels are almost identical. They have the same density, thermal conductivity, specific heat capacity, resistivity, elastic modulus, Poisson’s ratio, and melting point. This similarity means that both steels perform similarly in terms of physical behavior under thermal and electrical conditions, as well as elastic deformation.

The main differences between 1008 and 1018 steels are their chemical composition and mechanical properties, which affect their applications and performance in different environments.

Application of 1008 vs 1018 Steel

Selecting the right steel for your application is essential to ensure optimal performance, durability, and cost-effectiveness. Here, we compare typical applications of 1008 and 1018 steel grades to help you make an informed decision.

Application | 1008 Steel | 1018 Steel |

Automotive Parts | Body panels, tanks, brackets, and frames | Axles, gears, and engine parts |

Mechanical Parts | Low-stress mechanical parts | High-stress parts such as shafts, pins, and machine parts |

Construction | Roofing, siding, and structural panels | Structural supports, bolts, and fasteners |

Furniture | Lightweight frames and decorative elements | Structural components such as brackets and supports |

Welding | Components requiring extensive welding | Parts requiring moderate welding and machining |

Pipes and Tubing | Low-pressure piping | Hydraulic pipe, tubing, and mechanical piping |

Wire Products | Wire mesh, fencing, and nails | Wire, springs, precision wire |

Electrical Components | Low-stress electrical applications | Terminals, connectors and electrical enclosures |

Machinability of 1008 vs 1018 Steel

Machinability is an important property to consider when selecting steel for a manufacturing process, as it affects production efficiency and the quality of the final product.

Machinability of 1008 Steel

With a lower carbon content, 1008 steel is generally softer and therefore easier to form. This makes it particularly suitable for applications that require a lot of forming or shaping. The low carbon content reduces the likelihood that the steel will harden during deformation, making it less likely to crack or deform under machining stress. However, this same property may result in a surface that is not as smooth or clean as one made with harder steels.

Machinability of 1018 Steel

In contrast, 1018 steel, which has a slightly higher carbon content, has better machinability than 1008 steel. It tends to produce a better surface finish and retains a sharper edge and more precise dimensions after machining. The increased carbon content makes the surface harder, which is beneficial for reducing cutting tool wear and extending tool life. However, this hardness may make it more difficult to machine than 1008 steel.

Weldability of 1008 vs 1018 Steel

Weldability is a key factor in selecting steel for construction, manufacturing, and various engineering projects, as it directly affects the integrity and quality of the final assembly.

1008 Steel Weldability

This steel is considered an excellent material for welding due to its low carbon content, which minimizes the risk of creating brittle welds. The lack of excess carbon ensures that the weld area is less susceptible to cracking under stress, a common problem with higher carbon steels. 1008 steel is well suited for projects that require a lot of welding and is often used in welding applications for automotive body parts and sheet metal.

1018 Steel Weldability

1018 steel also has very good weldability, but its higher carbon content can present some challenges, such as increasing the risk of cracking if it is not properly preheated or cooled too quickly. Despite this, 1018 steel can be welded effectively with proper technique and is often used in manufacturing environments where its higher strength and hardness are required.

Formability of 1008 vs 1018 Steel

Formability is a key characteristic in steel selection, especially in industries where steel must be shaped into complex shapes without compromising structural integrity.

Formability of 1008 Steel

Due to its lower carbon content, 1008 steel has excellent ductility and formability. It is more ductile and easier to bend into a variety of shapes, making it a top choice for parts that involve deep drawing, bending, or complex forming operations. This property is especially valuable when manufacturing parts that require a high degree of deformation without the risk of cracking.

Formability of 1018 Steel

While 1018 is still formable, it is not as ductile as 1008 steel. The higher carbon content makes it slightly harder, which reduces its ability to be formed into complex shapes without heating. However, it has a higher strength than 1008 steel, which is an advantage for applications that require more structural integrity after forming.

Cost of 1008 vs 1018 Steel

When choosing a manufacturing or construction material, cost is a key factor that influences the decision.

Raw Material Prices

Market prices for 1008 and 1018 steel can fluctuate, but typically, 1008 steel is slightly cheaper due to its lower carbon content.

Manufacturing Costs

While raw material costs are an important factor, manufacturing costs will vary depending on the specific processes involved. 1018 steel may incur higher processing costs but may be more economical in the long run due to its durability and performance.

Compare 1008 vs 1018 steel prices now. Contact Huaxiao Metal for a free quotation.

Which One Should You Choose?

| Requirement | Recommended Steel |

|---|---|

| Cost Efficiency | 1008 |

| High Strength | 1018 |

| Better Machinability | 1018 |

| Formability | 1008 |

| General Purpose | Both |

In Conclusion:

Selecting the right type of steel requires balancing several factors, including mechanical requirements, cost, and the specific needs of the application. 1008 vs 1018 steels, both expertly processed by China TuoFa CNC Machining Services, have their place in the steel world.

1008 is suitable for parts that require extensive forming and welding, while 1018 excels in applications where strength and durability are critical. Each steel has unique advantages, and it should be selected to meet the specific needs of your project to ensure optimal performance and cost-effectiveness.