Copper and its alloys brass and bronze are widely used in industry and manufacturing. Despite their similar names, these three materials have significant differences in composition, properties, applications, and other aspects. Understanding these differences is important in choosing the right material. This article will explore the differences between copper, brass and bronze in detail to help you better understand these metal materials.

What is Copper?

Copper, also known as electrolytic copper, is a very high-purity copper, usually with a copper content of more than 99%. Red copper is known for its excellent electrical and thermal conductivity and is often used in electrical and electronic applications. It is bright red in color has good ductility, and can be drawn into thin wires or processed into thin sheets. Red copper is widely used in cables, electrical components, precision instruments, and some works of art, especially in applications requiring extremely high electrical conductivity.

What is Bronze?

Bronze is a metal alloy with a long history. It is mainly composed of copper and usually contains other elements such as tin, aluminum, manganese, and nickel. Due to its unique combination of ingredients, bronze has excellent mechanical properties and corrosion resistance, making it suitable for use in a variety of environments. The strength and hardness of bronze enable it to withstand large mechanical loads, while its wear resistance makes it excel in high-friction applications. In addition, bronze is easy to process and weld, allowing parts with complex shapes to be produced.

Due to its antibacterial properties, bronze is also widely used in sanitary environments. Bronze has a wide range of applications, including mechanical parts, works of art (such as sculptures and medals), construction materials (such as doors, windows, and decorative parts), and nautical equipment.

What is Brass?

Brass is an alloy of copper and zinc, with a copper content usually between 55% and 95% and a zinc content generally between 5% and 45%. Brass is named for its golden appearance and has good corrosion resistance and mechanical properties. Brass is easy to process into various shapes and is suitable for making valves, faucets, musical instruments, decorations and mechanical parts. Brass with different compositions also has different strengths, hardness and wear resistance, which can meet the needs of various applications.

Copper, Brass and Bronze

Chemical Composition

Copper

Copper is a metallic element found in nature with the chemical symbol Cu. Its purity is usually above 99%. The main properties of copper include good electrical conductivity, thermal conductivity, and corrosion resistance.

Brass

Brass is an alloy of copper and zinc, with the zinc content usually ranging from 5% to 45%. Brass can be divided into several types depending on the zinc content and other elements. Common brass grades include C26000 (ordinary brass) and C36000 (lead brass).

Bronze

Bronze is mainly composed of copper and tin, with the tin content generally ranging from 5% to 20%. Bronze can also contain other alloying elements (such as aluminum, nickel, or manganese) to improve its properties. Common types of bronze include aluminum bronze and manganese bronze.

Properties

Properties of Copper

Electrical Conductivity: Copper is one of the most conductive metals and is widely used in electrical and electronic products.

Thermal Conductivity: Good thermal conductivity makes it an ideal material for heat exchangers and wires.

Corrosion Resistance: Excellent in most environments, especially air and water.

Properties of Brass

Corrosion Resistance: Brass performs well in marine environments and can resist corrosion from salt water and moisture.

Strength: Brass is stronger than pure copper and is suitable for parts that are subjected to mechanical loads.

Machinability: Easy to machine and form, suitable for manufacturing parts with complex shapes.

Properties of Bronze

Corrosion Resistance: Bronze has excellent oxidation resistance and is suitable for use in marine and chemical environments.

Strength and Toughness: Bronze’s strength and toughness make it suitable for applications that are subjected to impact and wear.

Wear Resistance: Very suitable for making wear parts such as bearings and gears.

Appearance

Copper

Copper is bright red with a smooth surface. Over time, copper oxidizes and forms a black oxide film.

Brass

Brass is usually golden yellow and shiny. Different alloy ratios may cause color changes, and some brasses may also turn light brown during use.

Bronze

Bronze ranges in color from yellow-brown to dark brown, and over time, a green patina may form on the surface of bronze.

Applications

Applications of Copper

Copper is mainly used in electrical equipment, wires, cables, heat exchangers, and pipes. Due to its excellent electrical and thermal conductivity, copper plays an important role in electronic products and power transmission.

Applications of Brass

Brass is widely used in the manufacture of faucets, valves, musical instruments, decorations, and mechanical parts. Its good corrosion resistance and processing properties make it an ideal material for a variety of industrial and household products.

Applications of Bronze

Bronze is often used to manufacture wear-resistant parts, castings, ship accessories, sculptures, and architectural decorations. Its superior corrosion resistance and high strength make it very suitable for applications in harsh environments.

Prices

The price and availability of copper, brass and bronze vary depending on market demand, raw material costs, and production processes. Generally, pure copper has the highest price, while brass and bronze have relatively low prices due to their alloy properties.

Magnetism

Copper: Copper is a non-magnetic material that is almost unaffected by external magnetic fields and is suitable for use in electrical and electronic equipment.

Brass: Brass is also generally a non-magnetic material, especially brass with a low zinc content. In some cases, brass with a higher zinc content may exhibit weak magnetism.

Bronze: Bronze is also a non-magnetic material and is suitable for applications that require electromagnetic interference shielding.

Weldability

Copper: Copper has good weldability and is commonly used in welding and brazing techniques. It is suitable for a variety of welding methods, including arc welding and gas welding.

Brass: Brass has good weldability, but due to its high zinc content, it may produce pores during welding, so appropriate welding techniques need to be used.

Bronze: Bronze has poor weldability and usually requires the use of specific welding materials and techniques to avoid cracks during welding.

Mechanical Properties

Copper: Copper has good ductility and plasticity and can be stretched into filaments or processed into thin sheets.

Brass: Brass has higher strength and hardness, and is suitable for parts that bear greater loads.

Bronze: Bronze has better tensile strength and wear resistance than brass, and is suitable for applications that require high strength and wear resistance.

Copper Strip

Copper Strip Supplier and Manufacturer From China As a professional copper strip supplier, we not only provide high-quality products but also customized services to customers

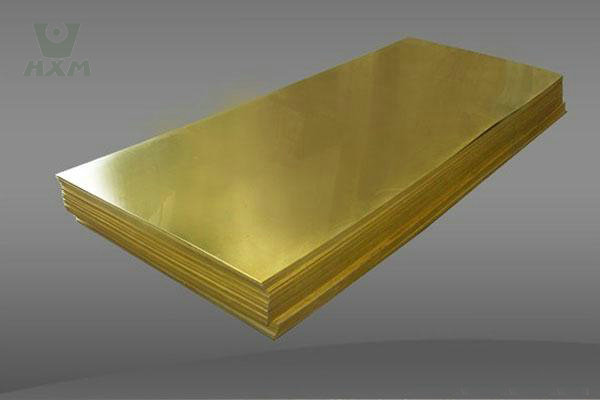

Copper Sheet/Plate

Copper Sheet Supplier and Manufacturer From China China Copper Sheet For Sale As one of the oldest copper sheet suppliers and manufacturers, Huaxiao Metal’s copper

Copper Coil

Copper Coil Supplier and Manufacturer From China China Copper Coil For Sale As one of the oldest copper coil suppliers and manufacturers, Huaxiao Metal’s copper

Copper Pipe

Copper Pipe Supplier and Manufacturer From China Copper Pipe As one of the long-established copper pipe suppliers and manufacturers, Huaxiao Metal’s copper tubes have excellent

Which one is Better? Copper, Brass and Bronze

There is no absolute “better” between copper, brass or bronze, but it depends on the specific application requirements and environment. Here are some selection suggestions:

If excellent electrical and thermal conductivity is required, copper is the best choice, especially for electrical and electronic equipment.

If corrosion resistance, good mechanical properties and moderate conductivity are required, brass is an ideal choice for faucets, valves and musical instruments.

If high strength, wear resistance and corrosion resistance are required, bronze will be a more suitable material, especially in harsh environments (such as marine applications or heavy industrial equipment).

Other Copper Alloys

Copper alloys are alloys with copper as the main component and other metal elements added to improve their properties. In addition to copper, brass and bronze, there are many other types of copper alloys. Here are some common copper alloys and their characteristics:

Phosphor Bronze

- Composition: It is mainly composed of copper and a small amount of phosphorus, and the phosphorus content is usually between 0.01% and 0.5%.

- Features: Phosphor bronze has good wear resistance, elasticity, and corrosion resistance. It is commonly used to make springs, gaskets electrical connectors, etc.

- Application: It is widely used in electrical and mechanical components, especially in occasions where high strength and wear resistance are required.

Aluminum Bronze

- Composition: It is mainly composed of copper and aluminum, and the aluminum content is generally between 5% and 11%.

- Features: Aluminum bronze has excellent strength, corrosion resistance, and wear resistance, and is suitable for high-strength and high-temperature environments.

- Application: It is commonly used in ship components, equipment in the oil and gas industry, aerospace parts, and high-performance mechanical components.

Nickel Copper

- Composition: Mainly composed of copper and nickel, the nickel content is usually between 5% and 30%.

- Features: Nickel copper alloy has good seawater corrosion resistance and excellent weldability, and has certain strength and toughness.

- Application: Widely used in marine engineering, chemical equipment, and shipbuilding industry.

Copper Zinc Alloy

- Composition: Mainly composed of copper and zinc, the zinc content is between 20% and 40%.

- Features: This alloy is superior to pure copper in strength and hardness, and has good processing properties.

- Application: Used to manufacture mechanical parts, building materials, and decorative parts.

Copper Magnesium Alloy

- Composition: Mainly composed of copper and magnesium, the magnesium content is generally between 2% and 6%.

- Features: This alloy has high strength and toughness, and can maintain stable performance in high-temperature environments.

- Application: Suitable for high-temperature and high-pressure engineering applications, such as engine parts and aircraft materials.

In Conclusion:

Copper, brass and bronze are three important metal materials, each with unique composition, properties and applications. Understanding the differences between them can help you make an informed decision when choosing the right material. Whether in industrial manufacturing or daily life, copper and its alloys play a vital role, providing reliable material support for all walks of life.