Incoloy 800 vs 825 are two widely used nickel-iron-chromium alloys that are known for their excellent corrosion resistance, mechanical strength, and suitability for high-temperature environments. While these alloys share many characteristics, they also have distinct differences that make them ideal for specific applications. This blog will explore the features, differences, and uses of Incoloy 800 and 825.

What Is Incoloy Alloy 825?

Incoloy 825 is a nickel-iron-chromium alloy with the addition of molybdenum, copper, and titanium. It is designed to provide exceptional resistance to reducing and oxidizing acids, stress corrosion cracking, and pitting. Incoloy 825 is particularly well-suited for chemical processing, pollution control, and oil and gas applications.

What Is Incoloy Alloy 800?

Incoloy 800 is a nickel-iron-chromium alloy with excellent resistance to oxidation, carburization, and nitridation in high-temperature environments. It retains its strength and stability at elevated temperatures, making it suitable for applications such as heat exchangers, furnace components, and petrochemical processing.

Incoloy 800 vs 825 Alloy – What’s the Difference?

Choosing between Incoloy 800 and Inconel Alloy 825 depends on several factors, including chemical composition, mechanical properties, and cost. Below, we break down the main differences:

Chemical Composition: Incoloy 800 vs 825 Alloy

| Element | Incoloy 800 | Incoloy 825 |

|---|---|---|

| Ni | 30–35% | 38–46% |

| Cr | 19–23% | 19.5–23.5% |

| Fe | Balance | Balance |

| Mo | – | 2.5–3.5% |

| Cu | – | 1.5–3% |

| Ti | ≤ 0.6% | 0.6–1.2% |

| C | ≤ 0.10% | ≤ 0.05% |

| Si | ≤ 1.0% | ≤ 0.5% |

| Mn | ≤ 1.5% | ≤ 1.0% |

Mechanical Behavior: Incoloy 800 vs 825 Alloy

| Property | Incoloy 800 | Incoloy 825 |

|---|---|---|

| Tensile Strength | ≥ 450 MPa | ≥ 550 MPa |

| Yield Strength | ≥ 170 MPa | ≥ 220 MPa |

| Elongation | ≥ 30% | ≥ 30% |

| Hardness (Rockwell) | B85–B90 | B88–B93 |

Physical Properties: Incoloy 800 vs 825 Alloy

| Property | Incoloy 800 | Incoloy 825 |

|---|---|---|

| Density | 7.94 g/cm³ | 7.94 g/cm³ |

| Melting Range | 1357–1385°C | 1370–1400°C |

| Thermal Conductivity | 11.2 W/m·K (at 100°C) | 11.1 W/m·K (at 100°C) |

| Specific Heat Capacity | ~502 J/kg·K | ~460 J/kg·K |

| Electrical Resistivity | 0.98 μΩ·m | 1.03 μΩ·m |

Application

- Incoloy 800: Ideal for high-temperature industrial applications such as heat exchangers and furnace components.

- Incoloy 825: Preferred for chemical processing, pollution control, and environments where acid resistance is critical.

Heat Resistance

Incoloy 800 is specifically engineered for high-temperature applications, withstanding temperatures up to 1100°C. Incoloy 825 can handle elevated temperatures but is better known for its corrosion resistance.

Corrosion Resistance

Incoloy 825 outperforms Incoloy 800 in environments with reducing agents, such as sulfuric acid and phosphoric acid, due to its molybdenum and copper content.

Cost

Incoloy 825 is generally more expensive due to its enhanced corrosion resistance and additional alloying elements. Incoloy 800 is more cost-effective for high-temperature but less corrosive conditions.

Main Standards

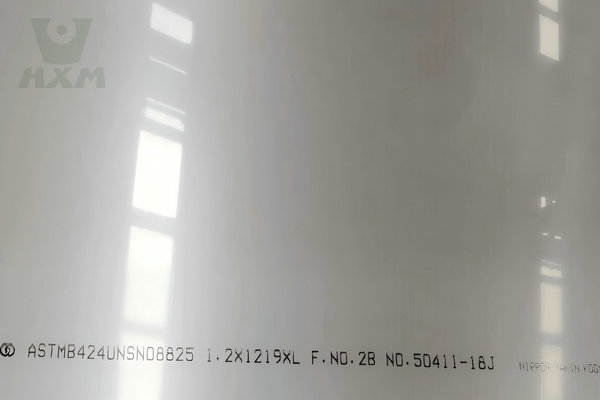

- Incoloy 800: ASTM B409, ASTM B407

- Incoloy 825: ASTM B424, ASTM B425

Fabrication and Weldability

Both alloys are highly fabricable and weldable, but care must be taken with Incoloy 825 to avoid contamination during welding, as its corrosion resistance depends on maintaining alloy purity.

Which is Better? Incoloy 800 vs 825 Alloy

The choice between Incoloy 800 and 825 depends on your application requirements:

- Choose Incoloy 800 for high-temperature, structural integrity-focused applications.

- Opt for Incoloy 825 in environments with aggressive corrosive agents, especially acids.

In Conclusion:

Incoloy 800 vs 825 each have unique strengths tailored to specific industrial needs. Understanding the differences in their chemical composition, mechanical properties, and corrosion resistance is critical for making an informed decision. Whether you need high-temperature durability or robust corrosion resistance, Huaxiao Metal offers a wide range of Incoloy products to meet your requirements. Contact us today for pricing and expert guidance!

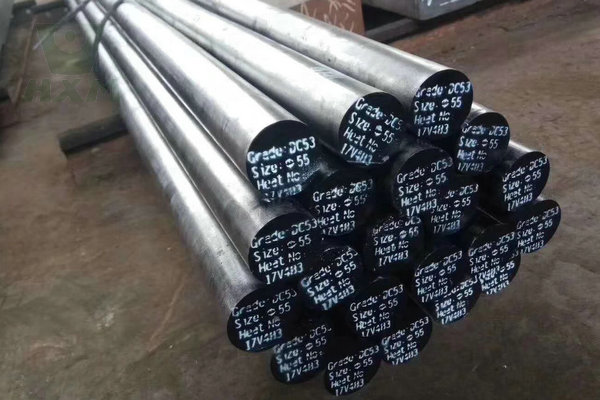

Huaxiao Special Alloy Steel Products

Incoloy Alloy

Incoloy Alloy Supplier and Manufacturer From China Incoloy alloys are a class of corrosion-resistant and high-temperature alloys widely used in petrochemical, chemical processing, seawater treatment,

Monel Alloy

Monel Alloy Supplier and Manufacturer From China Monel Alloy is a high-performance alloy composed of nickel and copper, known for its excellent corrosion resistance and

Inconel Alloy

Inconel Alloy Supplier and Manufacturer From China We specialize in providing high-quality Inconel alloys to meet the needs of various industrial applications. Inconel alloy is

Titanium Alloy

Titanium Alloy Supplier and Manufacturer From China Huaxiao Metal is a China and Asia wide supplier of metal and titanium raw materials to the industrial,

Precision Alloy

Precision Alloy Supplier and Manufacturer From China As a leading supplier of precision alloy steel, we provide high-quality alloy steel materials, which are widely used

Hastelloy Alloy

Hastelloy Alloy Supplier and Manufacturer From China We provide high-performance Hastelloy Alloy materials designed to cope with corrosion, thermal stress, and high-temperature requirements in extreme

High Temperature Alloy

High Temperature Alloy Supplier and Manufacturer From China As a leading supplier of high temperature alloys, we are committed to providing customers with high quality

Precipitation Hardening Stainless Steel

Precipitation Hardening Stainless Steel Supplier and Manufacturer From China Precipitation hardening stainless steel is known for its excellent high strength and corrosion resistance and is