Inconel metals are a family of nickel-based superalloys known for their outstanding resistance to high temperatures, corrosion, and oxidation. These alloys are widely used in industries such as aerospace, chemical processing, marine, and power generation due to their ability to maintain mechanical integrity in extreme environments.

When looking for Inconel suppliers and manufacturers, it is essential to consider factors such as quality certifications, material availability, and customer reviews. Whether you need Inconel 625, Inconel 718, or other grades, selecting the right Inconel manufacturers ensures you receive high-quality materials tailored to your specific needs.

What are Inconel Metals and Alloys?

Inconel metal and alloy is a family of nickel-based superalloys known for their exceptional resistance to heat, corrosion, and oxidation. These alloys are widely used in industries such as aerospace, marine, chemical processing, and power generation due to their ability to withstand extreme environments.

The prices of Inconel alloys depend on factors such as grade, size, and market conditions. To get accurate Inconel stock details and competitive rates, it is advisable to contact reputable Inconel suppliers directly. Bulk orders may qualify for discounts, while customized solutions can be tailored for specific industrial needs.

Common Types of Inconel Alloys

Inconel 600

Excellent corrosion and oxidation resistance.

Used in furnace components, chemical processing, and aerospace applications.

Inconel 625

Superior strength and fatigue resistance.

Common in marine, chemical processing, and nuclear industries.

Inconel 718

High strength and toughness, even at cryogenic temperatures.

Used in jet engines, gas turbines, and rocket motors.

Inconel X-750

Precipitation-hardened alloy with excellent mechanical properties.

Ideal for applications requiring high strength and corrosion resistance.

Inconel Alloys Data Sheet

Inconel Alloys Chemical Compositions

| Element (%) | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X-750 |

|---|---|---|---|---|

| Ni | 72.0 min | 58.0 min | 50.0-55.0 | 70.0 min |

| Cr | 14.0-17.0 | 20.0-23.0 | 17.0-21.0 | 14.0-17.0 |

| Fe | 6.0-10.0 | 5.0 max | Balance | 5.0-9.0 |

| Mo | – | 8.0-10.0 | 2.8-3.3 | – |

| Nb | – | 3.15-4.15 | 4.75-5.50 | 0.7-1.2 |

| Ti | – | – | 0.65-1.15 | 2.25-2.75 |

| Al | – | – | 0.2-0.8 | 0.4-1.0 |

| C | 0.15 max | 0.1 max | 0.08 max | 0.08 max |

| Mn | 1.0 max | 0.5 max | – | – |

| Si | 0.5 max | 0.5 max | – | – |

| S | 0.015 max | – | – | – |

The Mechanical Properties of inconel Metal

| Property | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X-750 |

| Tensile Strength (MPa) | 550-700 | 827-1034 | 965-1379 | 1000-1200 |

| Yield Strength (MPa) | 240-310 | 414-690 | 550-1100 | 600-800 |

| Elongation (%) | 30-45 | 30-50 | 10-25 | 15-25 |

| Hardness (HRC) | 30 max | 35 max | 40 max | 42 max |

The Physical Properties of Inconel Alloy

| Property | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X-750 |

| Density (g/cm³) | 8.47 | 8.44 | 8.19 | 8.28 |

| Melting Point (°C) | 1354-1413 | 1290-1350 | 1260-1336 | 1393-1427 |

| Thermal Conductivity (W/m·K) | 14.9 | 9.8 | 11.4 | 11.7 |

| Electrical Resistivity (µΩ·m) | 1.03 | 1.29 | 1.25 | 1.25 |

Characteristics of Inconel Alloys

High-temperature resistance – Retains strength and integrity at temperatures exceeding 1000°C.

Corrosion resistance – Excellent resistance to oxidation and aggressive chemicals.

Strength and durability – High tensile strength and fatigue resistance.

Versatility – Used in a variety of industries, including oil and gas, aerospace, and automotive.

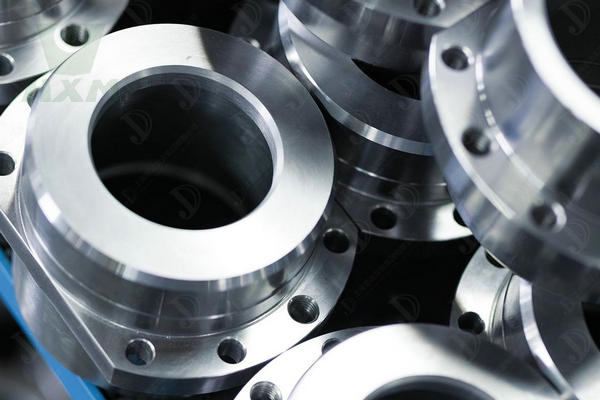

Applications for Inconel Alloys

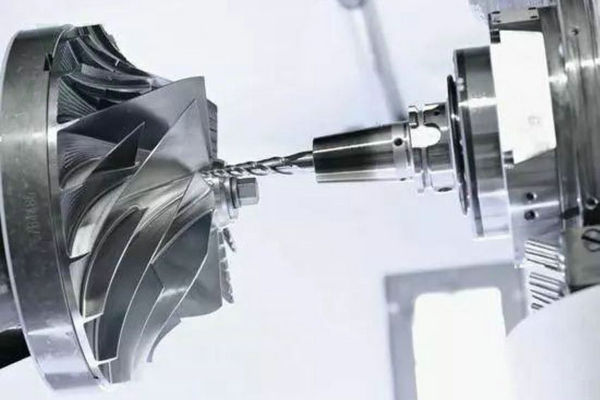

Aerospace Industry – Used in jet engines, exhaust systems, and turbine blades.

Oil and Gas Sector – Ideal for downhole equipment, heat exchangers, and piping systems.

Power Generation – Utilized in nuclear reactors, boilers, and gas turbines.

Chemical Processing – Excellent for heat exchangers, pressure vessels, and reactors.

Marine Applications – Corrosion-resistant properties make it ideal for shipbuilding and offshore drilling.

In Conclusion

Inconel metals and alloys are essential for industries requiring high-temperature resistance and superior corrosion protection. Whether you need Inconel suppliers, Inconel manufacturers, or are looking for the best Inconel prices and stock, choosing a trusted supplier is key to ensuring product quality and performance. Contact us now for the latest pricing and availability!

At Huaxiao Metal, we specialize in providing premium-quality Inconel metals sourced from top manufacturers. Our Inconel stock includes a wide range of grades, and we offer competitive Inconel prices to suit various industrial requirements. Contact us today for more details and a free quote on Inconel alloys.

Recommended Articles

Incoloy vs Inconel Alloy

Incoloy vs Inconel are two prominent superalloys known for their excellent performance in demanding environments. Both materials are widely used across various industries, but they

Inconel 718 VS Inconel X-750

Inconel alloys are known for their outstanding performance in high-temperature and corrosive environments. Among the most popular are Inconel 718 vs Inconel X-750, both nickel-chromium

Hastelloy vs Inconel Alloy

In industrial manufacturing, the choice of materials is crucial. Especially for applications involving high temperature and high corrosion environments, Hastelloy vs Inconel have become nickel-based

Inconel Vs Monel Alloy

When selecting materials for demanding industrial applications, Inconel vs Monel alloys often stand out due to their outstanding properties. This blog will explore the key

Inconel vs Titanium-The Ultimate Difference Explained

Inconel vs Titanium is widely regarded as high-specification metal materials with superior performance in industrial applications. Whether used in aerospace, medical devices, or chemical equipment,