Monel metal and alloys are essential materials for industries that require superior strength, corrosion resistance, and reliability. Widely used in marine, chemical, and aerospace applications, Monel’s unique properties make it a top choice for demanding environments. For manufacturers and suppliers looking to expand their stock or professionals looking for Monel for sale, this guide provides detailed insights into grades, properties, and applications. If you’re looking for competitively monel alloy priced or need reliable stock, read on to learn why Monel Metal is an important material.

What are Monel Metals and Alloys?

Monel is a nickel-copper alloy that contains approximately 65-70% nickel, copper and smaller amounts of iron, manganese, carbon and silicon. These alloys are prized for their excellent resistance to seawater and acidic environments. For suppliers and manufacturers, offering stocked Monel ensures that their customers have access to high-performance materials for a variety of industries.

Monel Metals and Alloys Grades

The most common grades of Monel alloys include:

Monel 400: Known for excellent corrosion resistance and strength. Popular among manufacturers and suppliers due to its versatility.

Monel K500: A precipitation-hardened version of Monel 400, offering higher strength and hardness, making it a premium choice for high-demand applications.

Monel 405: A free-machining grade of Monel 400, often sought after for precision machining projects.

For businesses dealing with Monel alloys, maintaining a stock of these grades is essential to meet the needs of buyers looking for quality materials at competitive prices.

Monel Alloys Data Sheet

Monel Alloys Chemical Compositions

Below is a table showcasing the chemical compositions of commonly available Monel alloys. For suppliers and manufacturers, providing this data ensures transparency for buyers seeking specific properties.

| Grade | Ni | Cu | Fe | Mn | C | Si |

|---|---|---|---|---|---|---|

| Monel 400 | 63-70% | 28-34% | ≤2.5% | ≤2% | ≤0.3% | ≤0.5% |

| Monel K500 | 63-70% | 27-33% | ≤2% | ≤1.5% | ≤0.25% | ≤0.5% |

| Monel 405 | 63-70% | 28-34% | ≤2.5% | ≤2% | ≤0.3% | ≤0.5% |

The Mechanical Properties of Monel Metal

Providing mechanical property data helps buyers compare grades and make informed decisions when purchasing from suppliers or manufacturers.

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Monel 400 | 480-620 | 170-345 | 35-45 |

| Monel K500 | 965 | 690 | 20-30 |

| Monel 405 | Similar to Monel 400 | Similar to Monel 400 | Similar to Monel 400 |

The Physical Properties of Monel Alloy

| Grade | Density (g/cm³) | Melting Range (°C) | Thermal Conductivity (W/m·K) |

|---|---|---|---|

| Monel 400 | 8.80 | 1300-1350 | 21.8 |

| Monel K500 | 8.44 | 1350-1400 | 20.9 |

| Monel 405 | Similar to Monel 400 | Similar to Monel 400 | Similar to Monel 400 |

Characteristics of Monel Alloys

Corrosion Resistance: With excellent resistance to seawater and acidic environments, Monel alloys are popular among suppliers catering to the marine and chemical industries.

High Strength: Ensures reliable performance in applications requiring durable materials.

Versatility: Easily fabricated, welded, and machined, making it a top choice for manufacturers.

Melting Point of Monel

The melting point of Monel Metal is usually between 1300°C and 1350°C, which allows it to remain stable in high temperature environments. However, different Monel grades vary slightly:

| Alloy | Melting Point Range (°C) |

|---|---|

| Monel 400 | 1300-1350 |

| Monel K500 | 1350-1400 |

| Monel 405 | Similar to Monel 400 |

This property makes monel alloy an ideal material for chemical equipment, heat exchangers and applications in high temperature environments. If you are looking for alloys suitable for high temperature applications, we are a monel alloy supplier and can provide you with specific material options and pricing information.

Benefits of Monel Alloys

Extended Service Life: Durable and resistant to wear, reducing maintenance costs.

Wide Application Range: Suitable for industries like marine, aerospace, and oil and gas.

Inventory Efficiency: A reliable choice for manufacturers and suppliers to keep in stock for high-demand applications.

What are the limitations of Monel?

Although Monel is known for its excellent performance, it also has some limitations that need to be considered when selecting materials:

Higher Cost:

Monel alloy is mainly composed of nickel and copper, which are expensive metals, resulting in a higher overall material cost. Budget-sensitive projects may prefer other alternatives.

Processing Difficulty:

Monel alloy’s high strength and toughness require more specialized equipment and techniques during processing, such as special tools and lower cutting speeds.

Performance in Oxidizing Environments:

In high-temperature oxidizing environments, Monel alloy may not be as corrosion-resistant as other nickel-based alloys, such as Inconel.

Magnetic Issues:

Although most Monel alloys are non-magnetic, they may be slightly magnetic in certain environments, such as after long-term use or cold working, which requires special attention.

For projects that need to balance cost and performance, Monel alloy suppliers and manufacturers can provide professional advice based on the specific application scenarios provided by customers to help customers choose the most suitable material.

Applications for Monel Alloys

Monel alloys are indispensable in:

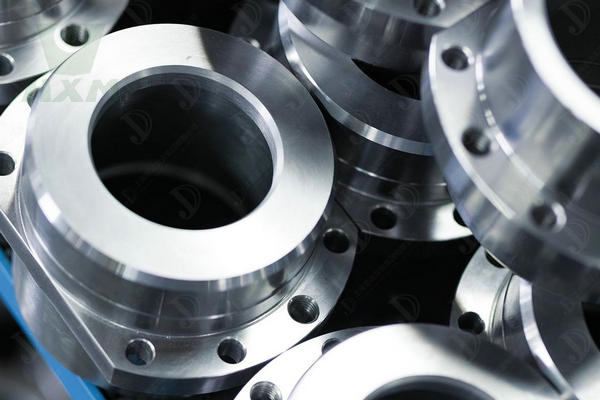

Marine Engineering: Used in propeller shafts, seawater pumps, and marine hardware.

Chemical Processing: Ideal for heat exchangers, reactors, and tanks exposed to harsh chemicals.

Oil & Gas: Suitable for valves, pipelines, and downhole tools in corrosive environments.

For manufacturers and suppliers, offering Monel alloys for sale ensures they can meet the needs of industries seeking dependable, high-performance materials.

Is monel alloy Magnetic?

Monel alloy is generally non-magnetic, which is one of the reasons why it is widely used in electronic equipment and marine fields. For example, both monel 400 and K500 have low magnetic permeability, making them suitable for applications that require non-magnetic properties, such as radar and sensor systems.

However, under certain specific conditions, such as long-term cold working or mechanical deformation, monel alloy may exhibit slight magnetism. This property is particularly important for precision equipment designers and manufacturers, and it is necessary to confirm the specific magnetic performance of the material with the supplier when purchasing.

If you have questions about the non-magnetic properties of monel alloy, or need more technical support, you can contact a reliable monel alloy supplier for professional advice and quotes.

In Conclusion

Monel metal and alloys are versatile materials with excellent strength, corrosion resistance and adaptability. For suppliers and manufacturers, having Monel alloy in stock ensures that a variety of industrial needs can be met. If you are looking for Monel metal or seeking pricing details, Huaxiao Metal is your trusted source of quality materials. Contact us today to discuss your requirements and get a competitive monel quote!

Recommended Articles

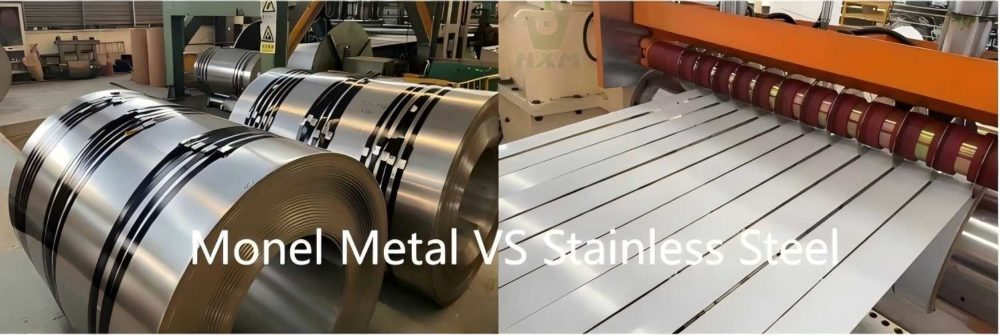

Monel Metal vs Stainless Steel

In industries where corrosion resistance, strength, and reliability are crucial, choosing the right material for specific applications can significantly affect performance and longevity. Two such

Monel vs Titanium Alloy

Monel vs titanium are two excellent choices when it comes to choosing the right material for your industrial application. Both materials offer unique advantages and

Inconel Vs Monel Alloy

When selecting materials for demanding industrial applications, Inconel vs Monel alloys often stand out due to their outstanding properties. This blog will explore the key

Monel Alloy

Monel Alloy Supplier and Manufacturer From China Monel Alloy is a high-performance alloy composed of nickel and copper, known for its excellent corrosion resistance and