In the fields of aerospace, medical technology, high-end manufacturing, etc., a silver-gray metal is quietly driving the revolution of human technology – titanium alloy. As the most strategically important metal material in the 21st century, titanium alloy occupies a core position in the global industrial landscape with its excellent performance.

This article will deeply analyze the technical characteristics, industry applications, and purchasing strategies of titanium alloys and reveal to you how Huaxiao Metal has become a titanium alloy solution expert trusted by global customers.

Titanium alloy: "Space Metal" that Redefines Metal Properties

The Scientific Code of Titanium Alloy

Titanium alloy is a metal material based on titanium, with aluminum, vanadium, molybdenum, and other elements added. This unique alloying treatment makes it have:

Extraordinary strength: The specific strength (strength/density ratio) is 1.3 times that of steel and 1.6 times that of aluminum alloy

Extreme corrosion resistance: The corrosion resistance in seawater and acid-base environments is more than 10 times that of stainless steel

Biocompatibility: The only metal material certified by the FDA for direct implantation in the human body

Temperature tolerance: Maintain stable performance in the range of -250°C to 600°C

Performance Parameter Comparison Table

Performance | Titanium Alloy | Stainless Steel | Aluminum Alloy |

|---|---|---|---|

| Density(g/cm³) | 4.5 | 7.9 | 2.7 |

| Tensile Strength(MPa) | 900-1200 | 500-800 | 300-500 |

| Seawater Corrosion Resistance | ★★★★★ | ★★★☆ | ★★ |

| High Temperature Stability | 600℃ | 300℃ | 200℃ |

6 Core Application Scenarios of Titanium Alloys

Aerospace

- Boeing 787 uses 15% titanium alloy components, reducing weight by 2.3 tons

- Engine compressor blades can withstand high-temperature airflow up to 650°C.

- Huaxiao Metal has passed NADCAP certification and supplies the Airbus A350 project

Medical Implant Field

- Orthopedic implants have a service life of more than 20 years

- Cardiovascular stent thickness is only 0.1mm

- Complies with ISO 5832 2/3 medical standards

Marine Engineering Field

- Deep-sea detector pressure shell material

- Seawater desalination device core components

- Offshore platform anti-corrosion structural parts

Chemical Equipment Field

- Anode basket assembly for chlor-alkali industry

- PTA device reactor lining

- Huaxiao special titanium-palladium alloy has a 40% increase in corrosion resistance

New Energy Field

- Hydrogen fuel cell bipolar plates

- Nuclear power steam generator pipes

- The TA18 alloy developed by Huaxiao has been used in the ITER project

Sports Equipment Field

- Golf club head hitting efficiency increased by 18%

- Competition-level bicycle frame weight reduced by 30%

- Tennis racket using Huaxiao β-type titanium alloy obtained ITF certification

High-quality titanium alloy supplier selection guide

Material Certification System

- Must hold international standard certifications such as AMS, ASTM, GB/T

- The medical field must pass the ISO 13485 quality management system

- Huaxiao Metal has obtained 12 international certifications, including AS9100D aviation certification

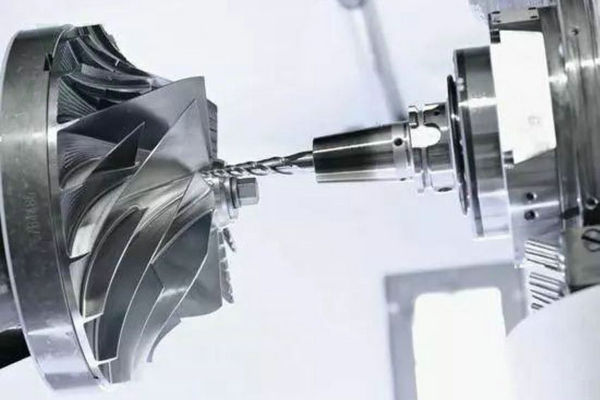

Production Process Capabilities

- Vacuum consumable arc furnace (VAR) melting technology

- Precision forging billet ratio of more than 5:1

- Huaxiao introduced the fully automatic rolling production line of the German SMS Group

Testing Laboratory Configuration

- Olympus ultrasonic flaw detector

- Zeiss metallographic analysis system

- Huaxiao Testing Center passed CNAS certification and issued international mutual recognition reports

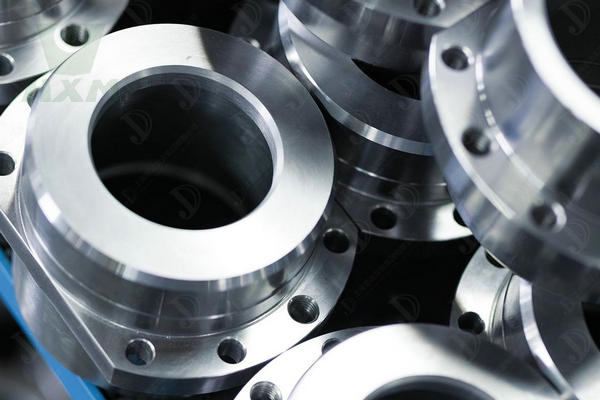

Special Specification Production Capabilities

- Ultra-thin plates (0.3mm) to ultra-thick plates (200mm)

- Large-size rings (diameter more than 5m)

- Huaxiao has completed a single 12-ton TC11 alloy forging

Technical Service System

- Material selection guidance

- Machining parameter optimization

- Huaxia0 provides full technical support from heat treatment to surface treatment

FAQ

What are the price components of titanium alloy materials?

It is mainly affected by the price of sponge titanium, alloy composition, processing difficulty, and order size. Huaxiao provides a step-by-step quotation system, and a 15% discount is available for 10,000-ton purchases.

How to choose TC4 and TA15 alloys?

TC4 (Ti-6Al-4V) is suitable for structural parts below 400℃, and TA15 (Ti-6.5Al-2Zr-1Mo-1V) is suitable for high-temperature environments of 550℃. Our engineers can provide free material selection consultation.

What should be paid attention to in titanium alloy welding?

TIG welding is required and oxygen must be strictly controlled. Huaxiang can provide pre-processing welding groove services.

Is there any Stock supply?

Conventional specifications TC4, GR5, GR7, etc. maintain a standing inventory of more than 200 tons.

Recommended Articles

Titanium vs Aluminum

When choosing between titanium vs aluminum, it is important to understand the differences in weight, strength, corrosion resistance, and applications. Both metals are widely used

Monel vs Titanium Alloy

Monel vs titanium are two excellent choices when it comes to choosing the right material for your industrial application. Both materials offer unique advantages and

Inconel vs Titanium-The Ultimate Difference Explained

Inconel vs Titanium is widely regarded as high-specification metal materials with superior performance in industrial applications. Whether used in aerospace, medical devices, or chemical equipment,

Titanium Steel vs Stainless Steel

Titanium Steel vs Stainless Steel are two commonly used metal materials in the industrial and construction fields. Each has unique properties and applications, but it

Why is Titanium Expensive? A Comprehensive Guide

Titanium has attracted much attention for its excellent performance and wide range of applications, but its high price often makes people feel daunted. What factors