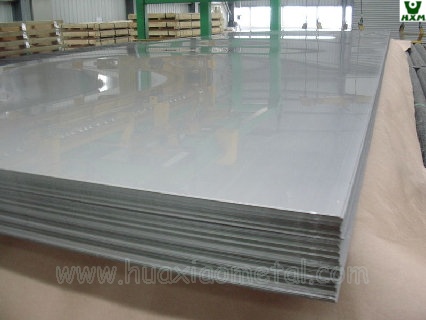

Cold Rolled Carbon Steel Coil/Strip/Sheet Manufacturers

As a leading manufacturer of carbon steel cold rolled coils/strips/sheets in the metal industry, we offer products that meet the highest quality standards, ensuring you get the best performance in a variety of applications. Whether you need cold rolled carbon steel coils, cold rolled carbon steel strips or cold rolled carbon steel sheets, our products are precision machined to have an excellent surface finish and excellent mechanical properties.

We are committed to providing you with the most competitive cold rolled carbon steel coils/strips/sheets prices and providing professional pre-sales and after-sales services to meet your specific needs. For more detailed information and the latest prices on cold rolled carbon steel products, please contact us directly.

Carbon Steel Cold Rolled Grade

Steel Grade: For Commercial Quality

JIS: G3141 SPCC

ASTM: A1008 CS Type A, B, C

SAE: 1008~1012 CQ

Steel Grade: For Drawing Quality

JIS: G3141 SPCD

ASTM: A1008 DS Type A, B

SAE: 1006~1008 DQ

Steel Grade: For Deep Drawing Quality

JIS: G3141 SPCE (N)

ASTM: A1008 DDS

SAE: 1006 DDQ

Cold Rolled Carbon Steel Available Size

Application of Cold Rolled Carbon Steel

Cold rolled carbon steel is a versatile material with numerous applications across various industries due to its excellent surface finish, dimensional accuracy, and mechanical properties. Here are some common applications:

Automotive Industry

- Applications: Body panels, structural components, and trim.

- Reasons: Cold rolled carbon steel’s smooth surface and uniform thickness make it ideal for stamping and forming parts with precise dimensions and high-quality finishes.

Construction

- Applications: Structural supports, roofing materials, and architectural elements.

- Reasons: Its strength and durability are suitable for both structural integrity and aesthetic purposes in building construction.

Home Appliances

- Applications: Washing machines, refrigerators, and ovens.

- Reasons: Cold rolled steel provides a clean, smooth surface that is ideal for painting and coating, essential for modern appliances.

Industrial Equipment

- Applications: Machinery components, brackets, and housings.

- Reasons: The material’s strength and precision are critical for ensuring reliable performance and longevity in industrial applications.

Furniture and Fixtures

- Applications: Office furniture, shelving units, and decorative fixtures.

- Reasons: Its ability to be easily shaped and finished makes it popular for both functional and decorative uses.

Consumer Goods

- Applications: Cans, containers, and various packaging solutions.

- Reasons: Cold rolled carbon steel’s formability and surface quality are perfect for producing items that require both strength and an appealing finish.

Electrical Applications

- Applications: Electrical enclosures, switchgear components, and transformer cores.

- Reasons: The material’s magnetic properties, combined with its workability, are advantageous for electrical and magnetic applications.

Precision Parts

- Applications: Small mechanical parts, fasteners, and precision tools.

- Reasons: Cold rolled steel’s tight tolerances and fine surface finish are crucial for parts requiring high precision.

Overall, cold rolled carbon steel’s combination of smooth surface, dimensional accuracy, and strength make it a preferred choice for applications requiring high quality and precise manufacturing.

Cold Rolled Carbon Steel Process

The cold rolled carbon steel process involves several key steps that enhance the steel’s properties, including its surface finish, dimensional accuracy, and mechanical strength. Here’s a detailed overview of the cold rolling process:

1. Steel Preparation

- Hot Rolling: Before cold rolling, the steel is often produced via hot rolling. Hot rolled steel is heated to high temperatures and then passed through rollers to achieve its desired thickness. This initial hot rolled product is then cooled to room temperature.

- Pickling: The hot rolled steel may undergo pickling to remove any surface oxides or scale that formed during the hot rolling process. This is typically done using acidic solutions.

2. Cold Rolling

- Process: The pickled hot rolled steel is fed into a cold rolling mill. Here, it is rolled at room temperature through a series of rollers. This reduces the thickness of the steel and increases its strength and hardness through strain hardening.

- Rolling Mills: The cold rolling is typically done using either a single reduction mill or a tandem mill. In a single reduction mill, the steel passes through one pair of rollers, while in a tandem mill, it passes through multiple pairs of rollers in sequence.

3. Annealing

- Purpose: After cold rolling, the steel is often annealed to reduce brittleness and improve its ductility and machinability. Annealing involves heating the steel to a specific temperature and then slowly cooling it.

- Process: This can be done in a controlled atmosphere furnace to avoid oxidation and ensure the desired properties.

4. Pickling (Post-Annealing)

- Purpose: If the steel was not pickled before cold rolling or if oxidation occurs during annealing, it may undergo pickling again to remove any surface oxides or scale.

- Process: Similar to pre-cold rolling pickling, this step uses acid solutions to clean the steel surface.

5. Tempering (Optional)

- Purpose: For some applications, the steel may be tempered to adjust its hardness and toughness. This involves heating the steel to a temperature below its critical point and then cooling it.

6. Coating (Optional)

- Purpose: Depending on the intended application, the cold rolled steel may be coated with various materials such as zinc (galvanization) or other protective layers to prevent corrosion and enhance its durability.

- Process: Coating methods include hot-dip galvanizing, electroplating, or applying a protective paint layer.

Coated Steel

7. Final Processing

- Inspection: The final cold rolled steel is inspected for thickness, surface quality, and other specifications.

- Cutting and Packaging: The steel is then cut to the desired length or shape and packaged for distribution.

Cold rolled carbon steel is widely used in various industries due to these improved properties, making it a versatile material for many applications.

Cold Rolled Carbon Steel VS Hot Rolled Carbon Steel

Cold rolled and hot rolled carbon steels are two distinct forms of carbon steel that differ significantly in their processing, properties, and applications. Here’s a detailed comparison between the two:

Carbon Steel Hot Rolled

Manufacturing Process

Hot Rolled Carbon Steel:

- Process: Produced by heating steel above its recrystallization temperature (usually above 1,700°F or 930°C) and then rolling it to the desired thickness. The steel is cooled at room temperature.

- Characteristics: The high temperature allows the steel to be easily shaped and formed. Hot rolling is generally used for large volumes of steel and is a cost-effective method for producing structural shapes.

Cold Rolled Carbon Steel:

- Process: Starts with hot rolled steel that is further processed at room temperature. The steel is passed through rollers to achieve a thinner gauge and a smoother surface. Cold rolling involves strain hardening, which increases the strength and hardness of the steel.

- Characteristics: Cold rolling provides better surface finish, tighter tolerances, and improved mechanical properties compared to hot rolling.

Surface Finish and Tolerance

Hot Rolled Carbon Steel:

- Surface Finish: Typically has a rough, scaled surface due to oxidation during the heating process.

- Tolerance: Generally less precise, with greater variations in thickness and width.

Cold Rolled Carbon Steel:

- Surface Finish: Has a smooth, clean surface that is free from scale and can be produced with a shiny appearance.

- Tolerance: Offers much tighter dimensional tolerances and more consistent thickness, which is important for applications requiring high precision.

Mechanical Properties

Hot Rolled Carbon Steel:

- Strength and Hardness: Generally has lower strength and hardness compared to cold rolled steel. The mechanical properties can vary due to the less controlled cooling process.

- Ductility: Typically more ductile, meaning it can be more easily formed into various shapes.

Cold Rolled Carbon Steel:

- Strength and Hardness: Higher strength and hardness due to strain hardening during the cold rolling process. This makes it suitable for applications requiring strong and durable materials.

- Ductility: Less ductile than hot rolled steel due to increased hardness, which may affect its formability.

Applications

Hot Rolled Carbon Steel:

- Common Uses: Structural beams, channels, plates, and other large sections where surface finish is less critical. Also used in the production of automotive components and heavy machinery.

- Advantages: Cost-effective and suitable for large-scale production.

Cold Rolled Carbon Steel:

- Common Uses: Automotive panels, appliances, furniture, and precision machinery parts where a smooth finish and exact dimensions are important.

- Advantages: Better surface quality and dimensional accuracy, making it ideal for applications that require a high degree of precision and aesthetics.

Cost

Hot Rolled Carbon Steel:

- Cost: Generally less expensive due to the simpler and more cost-effective production process.

Cold Rolled Carbon Steel:

- Cost: Usually more expensive because of the additional processing steps and higher energy consumption involved in achieving the desired properties.

Contact Shanghai Huaxiao's Cold Rolled Carbon Steel Manufacturers Now