First of all, congratulations to Amiu for successfully signing a contract with an Uruguayan customer and exporting the goods to Paraguay according to the customer’s requirements.

We are pleased to announce the successful shipment of FRP sheet and profiles to Paraguay, marking another milestone in our commitment to providing high-quality fiber reinforced plastic (FRP) products around the world. Our FRP sheets and profiles are designed to the highest industry standards, ensuring durability, strength and versatility for a wide range of applications. Whether you are in construction, automotive or industrial manufacturing, our FRP products are engineered to deliver superior performance and reliability.

Thank you customers for choosing us Huaxiao FRP sheet manufacturer and FRP profile manufacturers for the first time. Our company will serve you wholeheartedly.

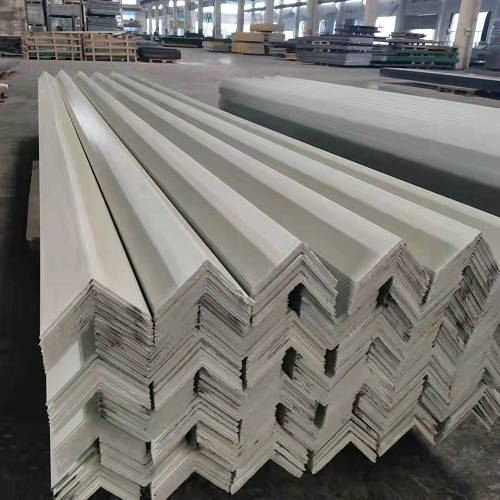

About FRP Sheet/Profile

We export FRP plates and FRP angle bars, please see the specific product specifications below. In addition to the following, we can provide other sizes and shapes, and have a large inventory. If you also need FRP/GRP steel, please get in touch with us directly for a quote!

transpor-tation | NO. | SPEC SIZE | QUANTITY | |||

PACKAGE | PCS | N.W.(MT) | G.W.(MT) | |||

40GP | 1 | GRP Sheet 4940x2000x2mm according drawing 6416-AP-200 Rev C | 1 | 220 | 6.16 | 6.46 |

2 | GRP Sheet 4940x2000x2mm according drawing 6416-AP-200 Rev C | 1 | 220 | 6.16 | 6.46 | |

3 | GRP Bent angle bar, Angle 60 ° according drawing 6416-AP-200 Rev C | 1 | 550 | 2.965 | 3.02 | |

4 | GRP Bent angle bar, Angle 60 ° according drawing 6416-AP-200 Rev C | 1 | 550 | 2.965 | 3.02 | |

5 | GRP Bent angle bar, Angle 60 ° according drawing 6416-AP-200 Rev C | 1 | 550 | 2.965 | 3.02 | |

6 | GRP Bent angle bar, Angle 60 ° according drawing 6416-AP-200 Rev C | 1 | 550 | 2.965 | 3.02 | |

Subtotal | 6 | 2,640 | 24.180 | 25.00 | ||

LCL | 7 | GRP bent angle bar, Angle 90 ° left according drawing 6416-AP-200 Rev C | 1 | 440 | 1.056 | 1.10 |

8 | GRP bent angle bar, Angle 90 ° right according drawing 6416-AP-200 Rev C | 1 | 440 | 1.056 | 1.10 | |

Subtotal | 2 | 880 | 2.112 | 2.20 | ||

Our FRP sheets and profiles are manufactured using advanced fiber reinforced plastic technology, combining high-strength fibers with a premium resin matrix. These sheets and profiles are available in a variety of sizes, thicknesses, and surface finishes to meet the specific needs of our customers. If you are sourcing FRP sheets, please contact us directly to get FRP sheet prices!

FRP Sheet Properties

| Y.S. | T.S. | Hardness | Density |

| (Mpa) | (Mpa) | HRC | kg/m³ |

| 169 | 118 | 30-38 | 1500 |

FRP Profile Properties

| Size | Resin | Glassfiber | Y.S. | T.S. | Oxygen Index | Flame Spread Index | Density |

| % | % | (Mpa) | (Mpa) | kg/m | |||

| GRP Bent angle bar, Angle 60 ° according drawing 6416-AP-200 Rev C | 35 | 65 | 262 | 288 | 29 | 14 | 1.20 |

| GRP bent angle bar, Angle 90 ° left according drawing 6416-AP-200 Rev C | 35 | 65 | 262 | 288 | 29 | 14 | 1.20 |

| GRP bent angle bar, Angle 90 ° right according drawing 6416-AP-200 Rev C | 35 | 65 | 262 | 288 | 29 | 14 | 1.20 |

FRP Fiberglass Plates Package

We usually use standard export packaging. If customers have other packaging requirements, please communicate in advance, and we can meet them.

Our FRP fiberglass panels are carefully packaged to ensure safe delivery and optimal performance. Each panel is wrapped in protective film and secured to a pallet to prevent damage during shipping. We offer:

- Standard packaging: Suitable for domestic and international shipping.

- Customized packaging: Tailor-made to specific customer requirements.

- Anti-scratch protection: Ensures the surface remains intact upon arrival.

FRP Angle Bar/Sheet - MTC

FRP Angle Bar/Sheet - BL

FAQ - Fiber Reinforced Plastic

What is Fiber Reinforced Plastic?

Glass Reinforced Plastic (GRP, or Fiber Reinforced Plastic, FRP) is a lightweight, high-strength material made of glass fiber and resin (such as epoxy resin, unsaturated polyester resin, etc.). It is not a metal, but a composite material, usually with fiber-reinforced plastic as the matrix material.

What is FRP Sheet?

Fiber Reinforced Plastic sheet is a plate-like material made of glass fiber and resin. It has excellent characteristics such as lightweight, high strength, corrosion resistance, and insulation.

Characteristics of FRP Sheet:

Lightweight and high strength: lighter than metal plate, but with good strength.

Corrosion resistance: suitable for humid or chemical corrosion environments, especially suitable for marine or chemical environments.

Weather resistance: UV resistance, high-temperature resistance, and aging resistance.

Good insulation: good electrical insulation performance makes it widely used in the power industry and electronic equipment.

Strong plasticity: various thicknesses and sizes of plates can be produced through molds, suitable for different needs.

Application of Fiber Reinforced Plastic Sheet:

Architectural decoration: used for exterior wall decoration, curtain walls, roofs, etc.

Industrial equipment: lining plates for chemical anti-corrosion storage tanks and tanks.

Transportation: lining plates for carriages and containers.

Power industry: partitions and insulation plates for electrical equipment.

Marine engineering: anti-corrosion ground, platform, and deck, etc.

What is Fiber Reinforced Plastic Angle Bar?

Fiber Reinforced Plastic angle bar is an L-shaped FRP profile, usually used for support or structural frames.

Characteristics of FRP Angle Bar:

High Strength and Lightweight: Compared with metal angle steel, it is lighter, but still provides the strength of structural support.

Strong Corrosion Resistance: Angle steel will not rust in humid, acidic, and alkaline environments, so it is widely used in chemical and marine environments.

Electrical Insulation: Suitable for occasions requiring electrical insulation, such as support structures in high-voltage electrical equipment.

Easy to Process: It can be cut, drilled, and assembled as needed to meet different design requirements.

Applications of FRP Angle Bar:

Support Frame: As a structural support for buildings and industrial equipment, it is used to manufacture brackets, frames, and other load-bearing structures.

Power Equipment: Used for support and protection structures in high-voltage electrical equipment.

Chemical Equipment: Used for support structures of chemical storage tanks, pipelines, etc.

Outdoor Platforms and Walkways: Especially in corrosive environments such as chemical plants and sewage treatment plants, FRP angle steel is widely used due to its corrosion resistance.

Characteristics of FRP:

Lightweight and High Strength: FRP is lighter than traditional metal materials, but has relatively high strength.

Corrosion Resistance: It has good tolerance to a variety of chemicals such as acids, alkalis, salts, and moisture, and is suitable for corrosive environments.

Good Insulation: FRP has good electrical insulation and thermal insulation properties.

Strong Plasticity: FRP can be made into complex shapes through molds, suitable for large-scale production.

Application of FRP:

Due to its excellent properties, FRP is widely used in many fields, such as:

Construction and Infrastructure: such as bridges, pipelines, storage tanks, etc.

Shipbuilding: hulls, yachts, etc. often use FRP materials due to their water resistance and lightness.

Automotive Industry: car bodies and parts.

Chemical Equipment: used for storage tanks, pipelines, and anti-corrosion linings.

Wind Power Generation Equipment: such as wind turbine blades, etc.

Are you looking for high-quality FRP sheets and profiles for your next project? Contact us today for a free quote and let our company help you find the FRP products that meet your needs. Improve the efficiency and durability of your project with our high-quality FRP sheet products!