The tin plate steel is thin, cold-rolled carbon steel coated with tin. The tin coating acts as a barrier to prevent water and air from corroding or damaging the steel.

As a leading tinplate manufacturer and exporter in China, we are proud to announce our latest shipment of tinplate to Canada. Our high-quality tinplate is widely used in packaging, construction and industrial applications. With competitive prices and excellent services, we aim to meet the growing demand for tinplate in the Canadian market. If you are looking for a reliable supplier, please feel free to contact us for a quote!

Tin Plate

Tin Plate Factory and Manufacturer For decades, Huaxiao Metal has been supplying high-quality tinplate and tin coated steel in a variety of specifications, coating weights,

About Tin Coated Steel Sheets

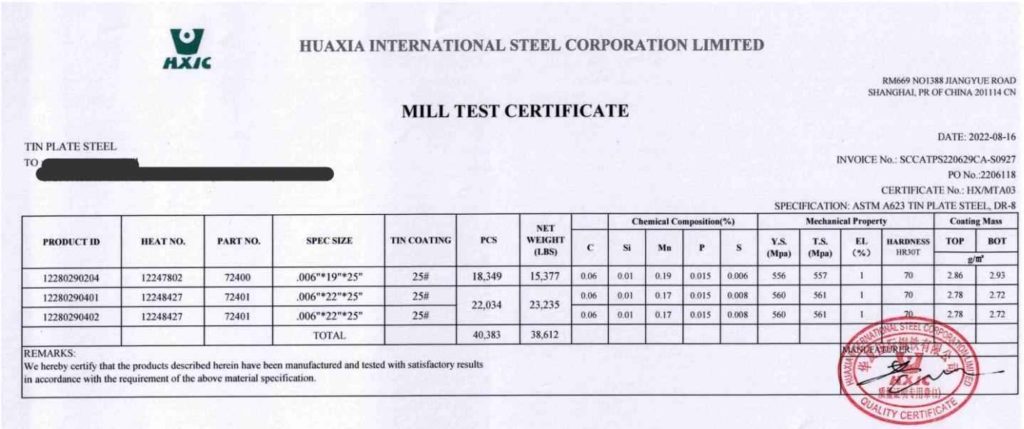

| ASTM A623 TIN PLATE STEEL, DR-8 | |||

| TIN COATING | SPEC SIZE | QUANTITY PCS | |

| 25# | .006″*19″*25″ | 18,349 | |

| 25# | .006″*22″*25″ | 22,034 | |

The size of each plate is 0.006″*19″*25″, and the content of tin plating on the surface of carbon steel about is 2.8g

| Coating Mass | |

| TOP | BOT |

| g/㎡ | |

| 2.86 | 2.93 |

| 2.78 | 2.72 |

| 2.78 | 2.72 |

These tinplates are perfect for making food cans, beverage containers, and other packaging solutions. We also offer custom sizes and coatings to fit your specific needs. Request a quote today to get the best tinplate prices for your project!

Tin Plate Steel Data Sheet - China Manufacturer

As a trusted China tin plate steel manufacturer, we provide detailed data sheets to ensure transparency and quality assurance. Below are the key properties of our tin coated steel sheets:

Tin Coated Steel Sheet Mechanical Property

| SPEC SIZE | Mechanical Property | |||

| Y.S. (Mpa) | T.S. (Mpa) | EL(%) | HARDNESS HR30T | |

| 0.006″*22″*25″ | 560 | 561 | 1 | 70 |

| 0.006″*22″*25″ | 560 | 561 | 1 | 70 |

Tin Coated Steel Sheet Chemical Composition

| SPEC SIZE | Chemical Composition(%) | ||||

| C | Si | Mn | P | S | |

| 0.006″*22″*25″ | 0.06 | 0.01 | 0.17 | 0.015 | 0.008 |

| 0.006″*22″*25″ | 0.06 | 0.01 | 0.17 | 0.015 | 0.008 |

Carbon Steel Sheet With Tin Package

Our tin-coated carbon steel sheets have excellent corrosion resistance and service life. These steel sheets are widely used in the food and beverage industry due to their non-toxic and environmentally friendly properties. The following picture shows our tin-coated carbon steel sheets:

We usually use standard export packaging. If customers have other packaging requirements, please communicate in advance, and we can meet them.

Tin Coating Steel Carbon Steel Sheet - MTC

We provide Mill Test Certificates (MTC) for all our tin plate steel sheets, ensuring compliance with international standards. Our products undergo rigorous quality checks to guarantee optimal performance. Here’s a glimpse of our MTC-certified tin plate steel sheets:

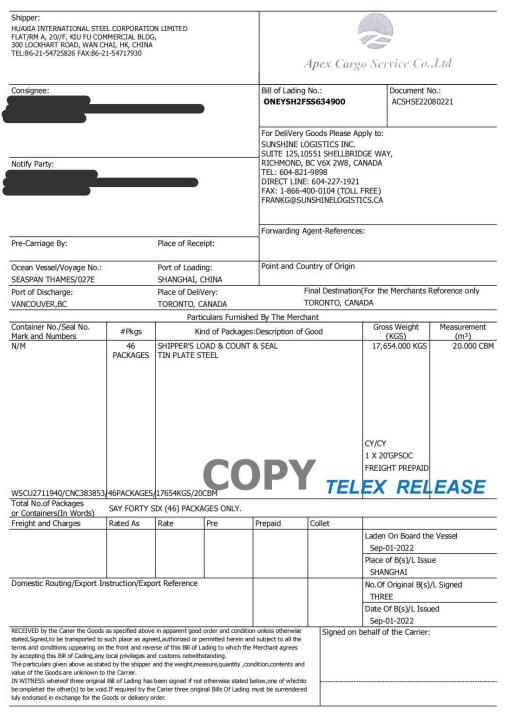

Tin Plated Steel Sheet - BL

If you’re looking for a trusted supplier of tin plate steel to Canada, don’t hesitate to contact us for a quote. Let us help you meet your project requirements with our premium products and services!

Why Choose Us Tin Plated Steel Sheet?

High-quality tin plate steel at competitive prices

Customizable sizes and coatings

Fast and reliable shipping to Canada

Detailed Mill Test Certificates (MTC) provided

Excellent customer support and after-sales service

If you’re looking for a trusted supplier of tin plate steel to Canada, don’t hesitate to contact us for a quote. Let us help you meet your project requirements with our premium products and services!