Cutting stainless steel sheets can be a bit challenging, as it is a hard and durable material. However, there are several methods that can be used to cut stainless steel sheet metal, depending on the tools and equipment available. Here are some common methods:

Cutting Shears:

Cutting shears are hand-held tools that can be used to cut thin stainless steel sheets. They work by applying pressure along a straight line to cut through the metal. This method is best suited for thinner sheets of stainless steel.

Circular Safor Cut Stainless Steel Sheet Metal:

A circular saw with a carbide-tipped blade can be used to cut through thicker stainless steel sheets. This method is best suited for straight cuts, and the use of a clamp or jig can help ensure accurate cuts.

Jigsawmfor Cut Stainless Steel Sheet Metal:

A jigsaw with a metal-cutting blade can be used to cut stainless steel sheets of curves and shapes. This method is best suited for thinner sheets of stainless steel.

Plasma Cutting:

Plasma cutting uses a high-temperature plasma torch to cut through stainless steel sheets. This method is best suited for thicker sheets of stainless steel and can produce precise cuts.

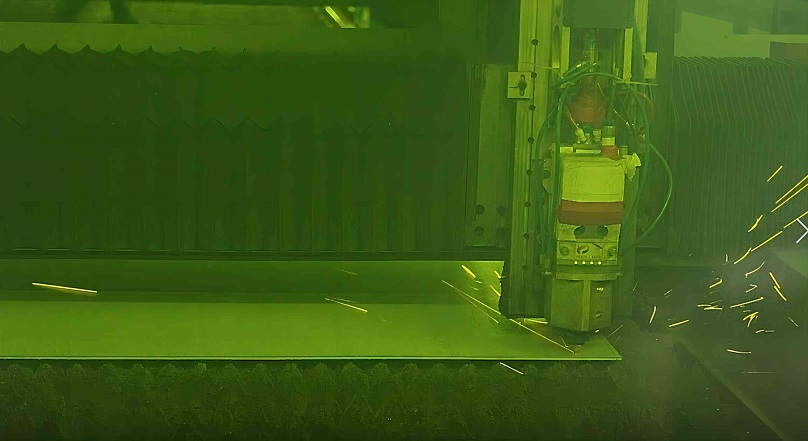

Laser Cutting:

Laser cutting uses a focused beam of light to cut through stainless steel sheets. This method is highly accurate and can produce intricate cuts, but it requires specialized equipment and can be more expensive.

Regardless of the method chosen to cut stainless steel sheet, it is important to wear appropriate safety gear, such as eye and ear protection and gloves, and to follow all manufacturer’s instructions for the tool or equipment being used.