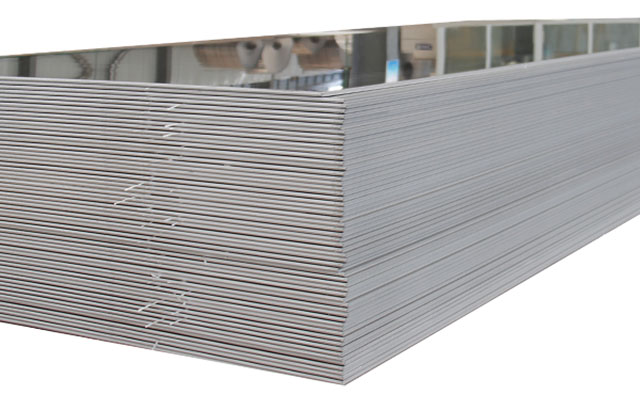

This article aims to explore and provide the numerical measurement of 16 gauge aluminum, shedding light on its dimensions and highlighting its relevance in different contexts.

Gauge System and Aluminum Thickness

- Introduction to the gauge system for measuring sheet metal thickness

- Explanation of the inverse relationship between gauge number and thickness

- Emphasizing the utilization of the American Wire Gauge (AWG) system for aluminum

The Thickness of 16 Gauge Aluminium

Clarification of the specific thickness of 16 gauge aluminum in inches and millimeters

- In the AWG system, 16 gauge aluminum is approximately 0.0508 inches or 1.29 millimeters thick

- Providing a precise numerical measurement for easy reference

| Specification | Value | Key takeaway |

|---|---|---|

| Thickness (Inches) | 0.0508 inches | Significantly thicker and more robust than 20g or 22g. |

| Thickness (Millimeters) | 1.29 mm | A versatile metric thickness for fabrication. |

| Weight (per square foot) | ~0.72 lbs / sq. ft (~3.5 kg / sq. m) | Noticeably heavier, indicating greater density and strength. |

| Planning a project? We supply high-quality 16g aluminum. Request a Free Quote Today! | ||

How Thick Is 22 Gauge Aluminum?

Determining the specific thickness of materials is crucial in various industries and applications. In the case of 22 gauge aluminum, understanding its precise thickness provides

How Thick Is 14 Gauge Aluminum?

Determining the specific thickness of materials is crucial in various industries and applications. In the case of 14 gauge aluminum, understanding its precise thickness provides

Applications and Significance for 16 Gauge Aluminum

Construction Industry:

Automotive Industry:

Why is it Important to Know the Tickness of 16 Gauge Aluminum?

Strength and Durability

Thickness directly affects the strength and durability of aluminum. Thicker aluminum can withstand greater pressure and impact and is suitable for high-strength applications.

Weight

Thickness is related to weight. Thicker aluminum is heavier, which is particularly critical in areas that require lightweight (such as aerospace and automotive manufacturing).

Processing Performance

Thickness affects the difficulty of processing. Thicker aluminum requires greater force and more complex processes, affecting production costs and efficiency.

Application Scenarios

Different thicknesses are suitable for different scenarios. No. 16 aluminum is often used in construction, automobiles, electronics and other fields. Understanding thickness helps to choose the right material.

Cost

Thickness affects the amount and price of materials. Thicker aluminum costs more. Understanding thickness helps to control the budget.

Thermal Conductivity and Electrical Conductivity

Thickness affects thermal conductivity and electrical conductivity. Thicker aluminum has better thermal and electrical conductivity and is suitable for radiators and electrical equipment.

Corrosion Resistance

Thickness affects corrosion resistance. Thicker aluminum is more durable in corrosive environments and is suitable for outdoor or harsh environments.

Standardization and Interchangeability

Understanding thickness helps ensure compliance with industry standards, guaranteeing interchangeability and compatibility of materials.

Engineering and Manufacturing Considerations

- Design and Tolerance:

- Exploring how knowledge of 16 gauge aluminium thickness aids in designing precise components

- Discussing the importance of accounting for thickness in achieving proper fit and functionality

- Manufacturing Techniques:

- Noting the influence of 16 gauge aluminum thickness on manufacturing processes such as cutting, bending, and welding

- Highlighting the significance of thickness in determining appropriate techniques for desired outcomes

Frequently Asked Questions

Understanding how to work with 16g aluminum is key to its successful implementation.

Can you bend 16 gauge aluminum?

Yes, but it requires significantly more force than 22g or 24g. While small pieces can be bent with hand tools and a sturdy vise, larger sheets require a sheet metal brake for clean, precise bends. It is less prone to cracking upon bending compared to some steel alloys.

Is 16 gauge aluminum easy to weld?

Welding 16 gauge aluminum is much more common and easier than welding thinner sheets. Both TIG and MIG welding processes can be used effectively by a skilled welder to create strong, reliable joints suitable for structural applications.

Is 16 gauge aluminum considered "structural"?

While it is significantly stronger than thinner gauges, it is generally considered “semi-structural.” It can bear moderate loads and is self-supporting, but it is not typically used for primary, load-bearing structural frames in large constructions. It is perfect for creating strong boxes, panels, and brackets.

In conclusion

The thickness of 16 gauge aluminum is precisely measured at approximately 0.0508 inches or 1.29 millimeters in the American Wire Gauge (AWG) system. This specific measurement holds significance in various industries, including construction and automotive, where 16 gauge aluminum is utilized in roofing panels, siding, and body panels. Understanding the numerical thickness facilitates accurate decision-making in engineering and manufacturing processes, ensuring optimal performance and functionality in the respective fields.