Today, Huaxiao Xiaobian will introduce to you how to choose the quenching heating speed of 7075 aluminum plates. Huaxiao Metal Co., Ltd. is a production and sales enterprise of aluminum plates, aluminum strips, bars, and aluminum tubes. Sheets, coils, bars, aluminum tubes, and other products.

1. The heating rate of the heat treatment process can damage the cold work hardening crystallization specifications of the heat treatment process, because the second phase is conducive to the cold work hardening component to be supercooled, and the high heating rate can ensure that the whole process of cold work hardening is caused before the second phase melts, thus It is beneficial to improve the nucleation rate and obtain this kind of cold work hardening crystallization, so the rapid heating method should be adopted.

2. From the viewpoint of improving production efficiency, rapid heating should also be used, because it can reduce heat treatment time, save energy and improve production efficiency.

3. When the heat treatment process commodity product has large specifications and models, complex shapes, large wall thickness differences, and large furnace loadings, if the heating rate is too fast, it is very likely that the heating will be opaque or uneven. There is a temperature difference in the core, which causes a very large thermal stress, and the heating rate should be controlled at this time.

4. When using single-stage enhanced heat treatment and tempering in the extremely high strength 7075 aluminum plate, the heating rate should be controlled, and the temperature should be raised at a slow rate. Generally, the temperature should be raised to 460~470°C at a rate not higher than 60°C/h, and then change the temperature control. Above 480°C, the purpose is to heat and temper all the AIZnMgCu phases with a low melting point, in addition, the S phase can be better melted, and the metal material can be prevented from causing coarse crystals.

Aluminium Metal Products

Perforated Aluminum Sheet

Perforated Aluminum Sheet As one of the Perforated Aluminum Sheet Suppliers with many years of experience in China, we are well aware of customers’ needs

Aluminum Wire

Aluminum Wire For Sale From China Aluminum Wire Supplier Aluminum Wire for Sale As one of the trusted aluminum wire suppliers and manufacturers in China,

Aluminum Pipe

Aluminum Pipe For Sale From China Aluminum Pipe Supplier Aluminum Pipe Suppliers and Manufacturer As one of the trusted aluminum pipe suppliers and manufacturers in

Aluminum Coil

Quality Aluminum Coil Suppliers and Manufacturers Welcome to Hxiao Metal, your trustworthy aluminum coil supplier and manufacturer! We are a company specializing in metal manufacturing

Aluminium Foil

Premium Aluminium Foil Suppliers and Manufacturers Welcome to Hxiao Metal, your trusted aluminum foil supplier and manufacturer! As a company specializing in metal manufacturing and

Aluminium Sheet

Quality Aluminium Sheet Suppliers in China Welcome to Hxiao Metal, your reliable supplier of high-quality aluminum sheets! We specialize in metal manufacturing and exporting, providing

Aluminum Tread Plate

aluminum tread plate sheet metal As one of the aluminum tread plate suppliers with many years of experience in China, we are well aware of

Aluminum Bar

Aluminum Bar Suppliers | Manufacturer | Factory Welcome to Huaxiao Metal! We are a company with more than ten years of metal manufacturing and export

Aluminum Strip

Aluminum Strip Suppliers and Manufacturers in China Welcome to Huaxiao Metal! As a company with more than ten years of experience in metal manufacturing and

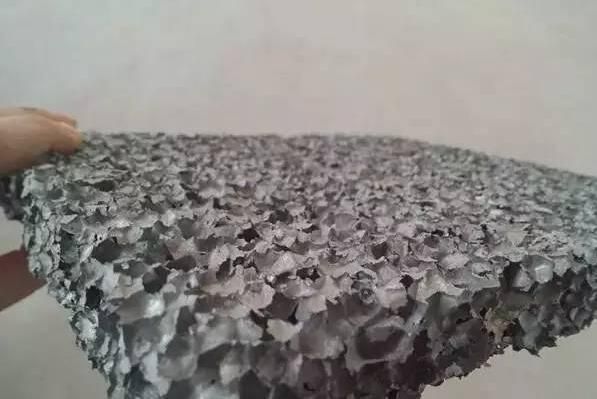

Aluminum Foam

Aluminum Foam Manufacturers Aluminum foam is an excellent material that combines versatility, durability and efficiency. As a leading aluminum foam supplier and manufacturer, Huaxiao Metal