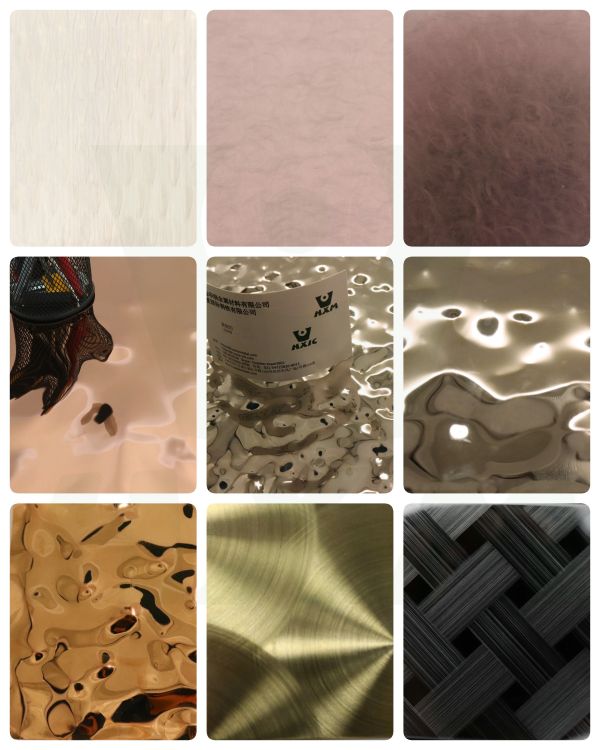

Regarding color stainless steel, is your first impression still that it only comes in one color? For example, stainless steel dishes and dishes, or is it the impression that stainless steel can only appear in heavy industry applications? But in fact, stainless steel can be seen everywhere in my mother’s life, such as the bronze doors of hotels, such as rose gold screens in home decoration, such as landscape basins in some courtyards… So the question is, how to achieve such colors of stainless steel Various, the editor will tell you about the coloring treatment of stainless steel colored plates.

Top 5 Methods to Color Stainless Steel

There are five common ways to stain stainless steel. They are chemical oxidation coloring, high-temperature oxidation coloring, electrochemical oxidation coloring, gas phase cracking coloring, and ion deposition oxide coloring.

1. Chemical Oxidation Coloring Method

This coloring method of stainless steel refers to the color of the film formed by the chemical oxidation of stainless steel in a specific solution, including the dichromate method, mixed sodium salt method, vulcanization method, acid oxidation method, and alkali oxidation method.

2. High-Temperature Oxidation Coloring Method

This method of coloring stainless steel is to maintain the stainless steel soaked in a specific molten salt under certain process parameters so that the stainless steel forms an oxide film of a certain thickness and presents various colors.

3. Electrochemical Coloring Method

This method is relatively simple. Stainless steel is colored through electrochemical oxidation, forming the color of the film in a specific solution.

4. Vapor Phase Cracking and Coloring Method

This stainless steel coloring method is rarely used in industry because the process is complicated and troublesome.

5. Ion Deposition Oxide Coloring Method

This method of coloring stainless steel is to put the stainless steel into a vacuum coating machine for vacuum evaporation. This method is suitable for processing large quantities of products. Because of the large investment and high cost, small-batch products are not cost-effective.

After the stainless steel is surface oxidized and colored in a special chemical coloring solution, it appears in various colors. This is not caused by the coloring of the surface coating but by the interference of light.

According to the principle of stainless steel coloring, it can be known that color changes on the surface of stainless steel are caused by changes in the composition of the surface oxide film. Therefore, no matter which stainless steel coloring method is used, attention must be paid to the control of time and potential.

Need help choosing a stainless steel coloring process? Get a quote or consult Huaxiao Metals now.

Stainless Steel Coloring Method Comparison Table

| Coloring Method | How It Works | Color Stability | Cost | Suitable for Mass Production | Common Applications |

|---|---|---|---|---|---|

| Chemical Oxidation | Forms an oxide film through chemical reactions in specific solutions | Moderate | Low | Yes | Decorative panels, signage, homeware |

| High-Temperature Oxidation | Creates oxide films via heating in molten salt baths | High | Medium | Limited | Industrial components, weather-resistant items |

| Electrochemical Coloring | Uses electric current in electrolytes to develop colored oxide films | High | Low-Medium | Yes | Appliances, architectural finishes |

| Vapor Phase Cracking | Gas-phase chemicals crack and react with the surface to form color | Low | High | No | Artistic pieces, experimental projects |

| Ion Plating (PVD) | Vacuum deposits metal ions forming a dense colored layer | Very High | High | Yes | Premium architectural decor, electronics |

Why Does Stainless Steel Change Color?

The color is not just on the surface but is created by the interference of light with oxide films of varying thickness. These films change the way light reflects off the surface, creating shades such as gold, blue, black ,and rose.

Tip: Regardless of the method used, precise control of time, temperature,e and potential is key to achieving consistent coloring results.

FAQ

Will coloring affect the rust resistance of stainless steel?

Processes such as high-temperature oxidation can enhance corrosion resistance, and some methods require additional protective coatings

How long can the colored surface last?

Chemical method 5-10 years, ion deposition method more than 20 years (outdoor environment)

Can all stainless steels be colored?

Austenitic 304/316 is the most ideal, and some ferrites can also be colored