In 2020, the “black swan” epidemic caused a blowout growth in the mask industry. The price of masks doubled, meltblown cloth increased 40 times, and meltblown cloth equipment was in short supply. At the same time, the 630 stainless steel material used in meltblown cloth equipment also became more valuable!

According to the tracking of I Want Stainless Steel, domestically, the price of 630 stainless steel used to manufacture meltblown cloth equipment has soared from 16,000-17,000 yuan before the New Year to the current 26,000-27,000 yuan/ton. The price of imported 630 has also soared to 45,000 yuan/ton. The price of 630 imported from Europe will be higher.

At present, meltblown cloth equipment is mainly concentrated in Europe. Due to the sudden outbreak of the epidemic, the demand for masks has exploded. As the main supplier of masks, China’s demand for meltblown cloth manufacturing machines has also been rising steadily. As an important part of meltblown cloth manufacturing equipment, the use of 630 flat steel is surging.

So where is 630 flat steel used in meltblown cloth? Why must 630 stainless steel be used in meltblown equipment?

With these questions, see the detailed answers below.

What Is 630 Stainless Steel?

Precipitation Hardening Stainless Steel

Precipitation Hardening Stainless Steel Supplier and Manufacturer From China Precipitation hardening stainless steel is known for its excellent high strength and corrosion resistance and is

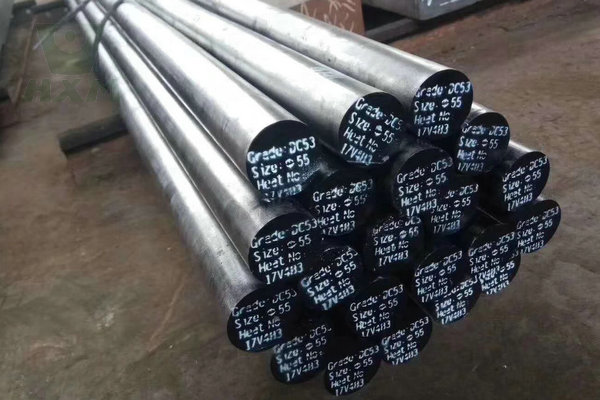

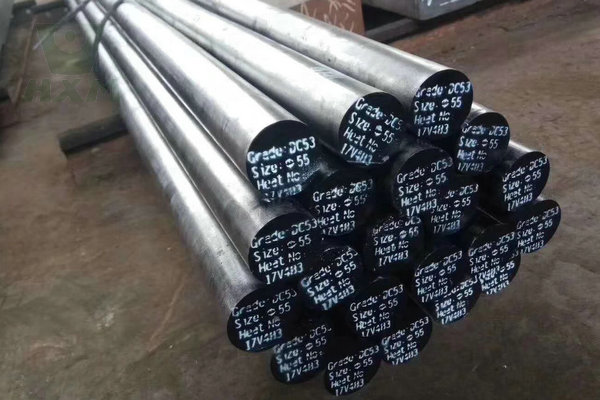

630 stainless steel is a precipitation, hardening, martensitic stainless steel composed of copper, niobium/columbium.

It is also commonly known as 17-4PH stainless steel, with 17 Cr content, and 4 Ni content, and PH is the English for precipitation hardening steel.

It has high strength, high hardness, good welding performance, and corrosion resistance. At present, it has been widely promoted and used in valves, shafts, and chemical fiber industries and high-strength parts with certain corrosion resistance requirements.

The national standard grade is 0Cr17Ni4Cu4Nb stainless steel, new 05Cr17Ni4Cu4Nb stainless steel.

SUS630 Stainless Steel Chemical Composition

| C | Si | Mn | S | P | Cr | Ni | Cu | Nb |

| ≤0.07 | ≤1. 00 | ≤1.00 | ≤0.030 | ≤0.035 | 15. 50~17.50 | 3.00~5. 00 | 3. 00~5.00 | 0. 15~0. 45 |

The performance characteristics of 630 stainless steel are that the strength level can be easily adjusted, which can be adjusted by changing the heat treatment process. The martensitic phase transformation and aging treatment to form precipitation hardening phase are its main strengthening means. 630 stainless steel has good attenuation performance, strong corrosion fatigue resistance and water drop resistance.

Precipitation hardening steel with copper added. Used to manufacture shafts and turbine components.

This grade has high strength, hardness (up to 3008°C/572°F) and corrosion resistance.

After heat treatment, the mechanical properties of the product are more perfect, and the compressive strength can reach up to 1100-1300 mpa (160-190 ksi).

This grade cannot be used at temperatures above 300°C (572°F) or at very low temperatures. It has good corrosion resistance to the atmosphere and dilute acids or salts. Its corrosion resistance is the same as 304 and 430.

Main Application Areas

Offshore platforms, helicopter decks, other platforms

Food industry

Pulp and paper industry

Aerospace (turbine blades), mechanical parts

Nuclear waste barrels

Huaxiao Special Alloy Steel Products

Incoloy Alloy

Incoloy Alloy Supplier and Manufacturer From China Incoloy alloys are a class of corrosion-resistant and high-temperature alloys widely used in petrochemical, chemical processing, seawater treatment,

Monel Alloy

Monel Alloy Supplier and Manufacturer From China Monel Alloy is a high-performance alloy composed of nickel and copper, known for its excellent corrosion resistance and

Inconel Alloy

Inconel Alloy Supplier and Manufacturer From China We specialize in providing high-quality Inconel alloys to meet the needs of various industrial applications. Inconel alloy is

Titanium Alloy

Titanium Alloy Supplier and Manufacturer From China Huaxiao Metal is a China and Asia wide supplier of metal and titanium raw materials to the industrial,

Precision Alloy

Precision Alloy Supplier and Manufacturer From China As a leading supplier of precision alloy steel, we provide high-quality alloy steel materials, which are widely used

Hastelloy Alloy

Hastelloy Alloy Supplier and Manufacturer From China We provide high-performance Hastelloy Alloy materials designed to cope with corrosion, thermal stress, and high-temperature requirements in extreme

High Temperature Alloy

High Temperature Alloy Supplier and Manufacturer From China As a leading supplier of high temperature alloys, we are committed to providing customers with high quality

Precipitation Hardening Stainless Steel

Precipitation Hardening Stainless Steel Supplier and Manufacturer From China Precipitation hardening stainless steel is known for its excellent high strength and corrosion resistance and is