Carbon steel is a widely used material in various industries due to its exceptional properties. One popular variant of carbon steel is 1045, renowned for its balance of hardness, strength, and affordability. In this article, we will delve into the characteristics, applications, advantages, and limitations of 1045 carbon steel to determine its overall quality and suitability for different purposes.

What is 1045 Steel?

1045 steel is a medium carbon steel with a carbon content of approximately 0.45%. It has excellent tensile strength, good toughness and weldability. This makes it ideal for manufacturing components that require high wear resistance and high stress strength, such as gears, shafts, axles, bolts and automotive parts.

Huaxiao Metal provides 1045 steel to a wide range of industries including automotive, construction, agriculture and heavy equipment manufacturing.

Understanding 1045 Steel Data Sheet

Chemical Composition

| Element | Content (%) |

|---|---|

| C | 0.43 – 0.50 |

| Si | 0.17 – 0.37 |

| Mn | 0.60 – 0.90 |

| P | ≤ 0.040 |

| S | ≤ 0.050 |

| Fe | Bal |

Please note that these values represent general ranges and may vary from specific production batches. The carbon content determines the hardness and strength characteristics of 1045 carbon steel while alloying elements such as silicon and manganese can have an impact on the material’s processability and mechanical properties. Phosphorus and sulfur levels are usually low to ensure good machinability and weldability.

Hardness and Strength

| Performance | Value |

|---|---|

| Hardness (HRC) | 16 – 22 |

| Tensile Strength (MPa) | 585 – 760 |

| Yield Strength (MPa) | 450 – 630 |

| Impact Toughness | Rotary Bending Diameter (mm): 20 |

These values represent the general range of properties for 1045 steel. The hardness value is expressed in Rockwell hardness (HRC), the higher the value, the harder the material. Tensile strength is the ability of a material to resist fracture under stress, while yield strength is the stress level at which a material begins to deform plastically. Impact toughness refers to the energy absorption capacity of a material when subjected to impact loads, usually measured in terms of rotational bending diameter.

It is important to note that these values are general ranges and that actual values may vary depending on specific material handling and testing methods. In practice, the hardness and strength of 1045 steel can provide the appropriate material properties to meet the needs of many applications.

Machinability

- Good machinability: Material 1045 steel has good machinability under proper tools and cutting conditions, and can be used in machining operations such as milling, turning, drilling and cutting.

- Ease of grinding: 1045 steel has good grinding performance and can be used for fine grinding and surface finishing operations.

- Cold deformation: Material 1045 steel can be cold deformed at room temperature, such as cold forging, bending, and forming.

- Thermally deformable: In an appropriate temperature range, material 1045 steel can also be thermally deformed, such as hot forging, hot rolling, and hot extrusion.

- Appropriate cutting parameters are required: Due to the high hardness and strength of 1045 carbon steel, appropriate cutting speed, feed rat,e and cutting lubrication conditions need to be selected during processing to ensure good cutting effect and tool life.

It should be noted that the specific processing and heat treatment state of the material will also affect the machinability of 1045 steel. In the actual processing process, the appropriate process and tool should be selected according to the specific needs and processing requirements to ensure good processing results.

Applications of 1045 Carbon Steel

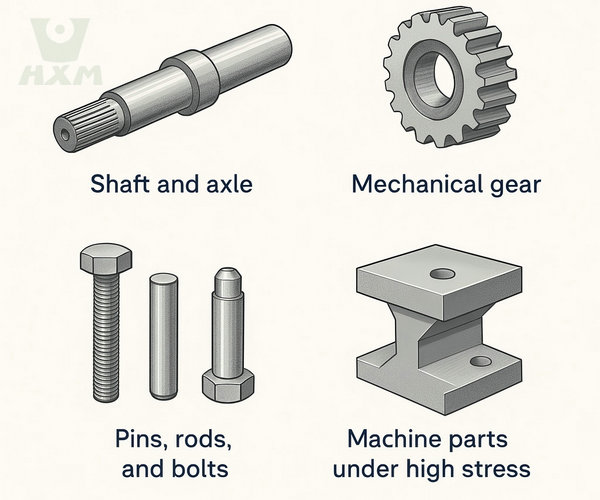

1045 carbon steel is widely used in many fields due to its moderate hardness, strength, and machinability. The following are the common application areas of 1045 carbon steel:

- Automobile industry: 1045 carbon steel has important applications in automobile manufacturing. It can be used to make components such as gears, camshafts, crankshafts, prop shafts, and car frames. It’s high strength and good wear resistance make 1045 carbon steel ideal for automotive drivelines and structural components.

- Mechanical equipment: 1045 steel is widely used in the field of mechanical equipment manufacturing. It can be used to manufacture machine tool components, bearings, gears, shafts, pins, etc. The wear resistance and strength of 1045 carbon steel make it suitable for components subject to high loads and frequent use.

- Tools and Cutting Utensils: Due to its moderate hardness and machinability, 1045 carbon steel is widely used in tool making. It can be used to make hammers, chisels, pliers, blades and knives, etc. The machinability of 1045 carbon steel makes it suitable for operations such as chipping, striking, and cutting.

- Construction and Structural: 1045 carbon steel has a role to play in the field of construction and construction. It can be used to manufacture support structures, connectors, and various components. Its high strength and durability make 1045 carbon steel an important material in projects such as buildings and bridges.

- Other fields: In addition to the above fields, 1045 carbon steel can also be used in agricultural machinery, shipbuilding, the oil and gas industry, and other fields. Its versatility allows 1045 carbon steel to play an important role in several industries.

To sum up, 1045 carbon steel is widely used in many fields such as the automobile industry, mechanical equipment, tool manufacturing, construction, and structure due to its moderate hardness, strength, and machinability. Its excellent properties make it an ideal choice for many applications.

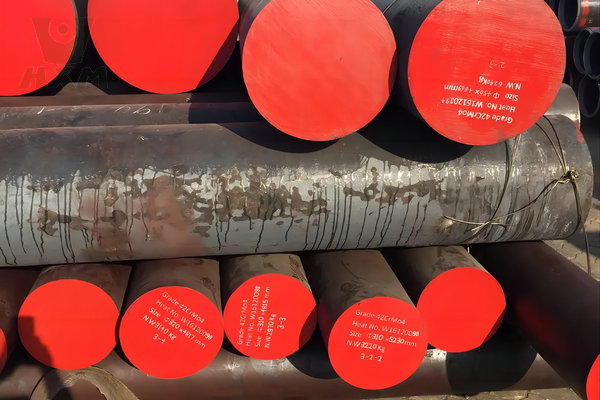

We maintain large inventories of 1045 steel for sale in sheet, plate, and round/square bar formats.

If you are looking for 1045 steel, welcome to contact us directly, we will provide you with competitive 1045 steel prices and fast delivery.

Is 1045 Carbon Steel Good?

Is 1045 carbon steel good? Next, let’s discuss why it is good. What are the advantages?

Good Strength and Hardness:

1045 carbon steel has moderate strength and hardness which makes it perform well under high loads and stresses. This makes it suitable for many applications requiring strength and durability.

Excellent Machinability:

1045 carbon steel has good machinability, making it easy to perform machining operations such as cutting, milling, drilling, and forming. It maintains good cutting performance and surface quality while facilitating fine machining.

Excellent wear resistance:

1045 carbon steel has good wear resistance, making it excellent in situations where resistance to wear and friction is required. This makes it ideal for gears, camshafts, bearings, and other components requiring wear resistance.

Strong Durability:

1045 carbon steel has good durability, able to maintain its performance and shape for a long time. It can withstand repeated loads and frequent use without deformation or fatigue fracture, extending the service life of components.

Affordable:

Relative to some high alloy steel grades, 1045 carbon steel has a lower cost, making it an affordable choice. It offers excellent performance and processability while reducing manufacturing costs.

Versatility:

1045 carbon steel has a wide range of applications and is suitable for many industries such as the automotive industry, machine building, tool making, construction, and structure. Its versatility makes it a versatile material in many applications.

In general, 1045 carbon steel has good strength, hardness, and machinability, excellent wear resistance, high durability, and is economical. These advantages make 1045 carbon steel one of the most commonly used materials in many industries.

Why Choose Huaxiao Metal as Your 1045 Steel Supplier?

As a trusted 1045 steel supplier and manufacturer, Huaxiao Metal offers:

High-quality 1045 steel sheets, plates, and bars, etc.

Full compliance with ASTM A29 and other global standards

Fast global shipping and reliable packaging

Professional team support for technical and sourcing inquiries

Flexible MOQ and custom dimensions upon request

If you’re searching for 1045 steel for sale, we invite you to contact us directly for competitive 1045 steel prices and fast delivery options.

In Conclusion

As a common material, 1045 carbon steel shows excellent performance and wide application in many fields. In summary, 1045 carbon steel has the following characteristics and advantages:

- Chemical composition: The chemical composition of 1045 carbon steel includes moderate carbon, silicon, manganese and trace amounts of phosphorus, sulfur and other elements, ensuring good hardness, strength and machinability.

- Hardness and Strength: 1045 Carbon Steel has moderate hardness and strength characteristics that allow it to withstand high loads and stresses for a wide variety of application needs.

- Machinability: 1045 carbon steel has good machinability, which is convenient for machining operations such as cutting, milling, drilling and forming.

- Application fields: 1045 carbon steel is widely used in the automobile industry, machinery and equipment manufacturing, tool manufacturing, construction and structure and other fields to meet the needs of various parts and structures.

- Advantages: The advantages of 1045 carbon steel include good strength, hardness, machinability, and wear resistance, high durability, affordability, and versatility.

To sum up, 1045 carbon steel, as a commonly used material, exhibits good performance and reliability in many applications. Its moderate hardness, strength, and machinability make it an ideal choice in various industries, providing a reliable material solution for a variety of applications.