What is 45 steel? No. 45 steel is a common carbon steel, where “45” indicates that its average carbon content is 0.45%. This kind of steel has good hardness and wear resistance, so it is widely used in machinery manufacturing, construction, tools, and other fields.

Introduction to 45# Steel

Whether you are manufacturing durable mechanical parts or looking for reliable structural component materials, 45 steel provides unmatched performance and value.

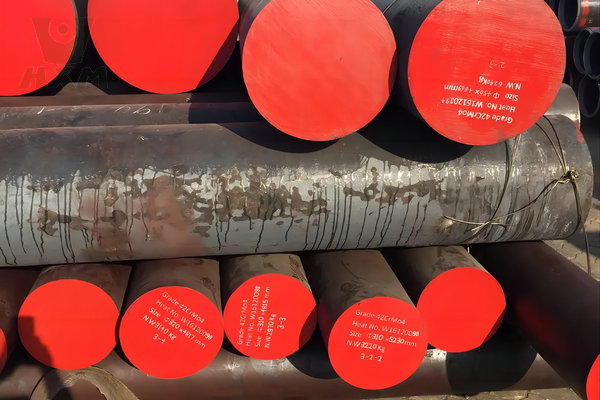

Huaxiao Metal is one of your trusted partners for quality 45 material steel products. We offer a comprehensive inventory of 45 steel in various shapes and sizes to meet your specific requirements.

Contact us today for a free quote and learn why 45# steel has the right properties for your application!

Chemical Composition of 45 Steel:

С | Si | Mn | P | Ni | Cr | S | Cu | As | Fe |

0.42-0.5 | 0.17-0.37 | 0.5-0.8 | <0.035 | <0.25 | <0.25 | <0.04 | <0.25 | <0.08 | Bal |

Mechanical Properties of 45# Steel:

| Normalizing | 850℃ |

| Quenching | 840℃ |

| Tempering | 600℃ |

| Tensile Strength | ≥600Mpa |

| Yield Strength | ≥355Mpa |

| Elongation | 16% |

| Shrinkage | 40% |

| Impact Energy | 39J |

| Hardness of the delivery condition | |

| Hot rolled steel | ≤229HB |

| Annealed steel | ≤197HB |

Physical Properties of 45# Steel:

| Physical Properties | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | ≈1420-1460℃ |

| Thermal Conductivity | 50.2 W/(m·K) |

| Linear Expansion Coefficient | 11.9 × 10⁻⁶ /K (20-100℃) |

| Elastic Modulus | 210 GPa |

45# Equivalent Steel Grade:

Japan JIS Standard Grade is S45C/S48C;

Germany DIN Standard Material No. is 1.0503;

UK BS Standard Grade is IC45/080A47;

Italy UNI Standard Grade is C45;

Spain Standard Grade is F.114;

American AISI/SAE Standard Grade is 1045;

International Standard Organization ISO Standard Grade is C45E4.

Manufacturing Process of 45 Steel:

45# steel is usually manufactured using smelting methods, including electric arc furnace smelting and converter smelting. After casting, the steel needs to undergo processes such as continuous casting, rolling and annealing to obtain the required shape and properties.

Performance Characteristics:

No. 45 steel has high strength, hardness and wear resistance but also low toughness. After heat treatment, it can obtain higher hardness and better wear resistance. This kind of steel has good cutting performance and relatively low price, so it is an economical engineering material.

Application Fields of 45# Steel:

No. 45 steel is widely used in machinery manufacturing, construction, tools, and other fields. For example, it can be used to make mechanical parts such as shafts, gears, pins, connecting rods, nuts and bolts. Additionally, it can be used to make tools such as knives, gauges, and molds.

Heat Treatment of 45# Steel:

Heat treatment of No. 45 steel can include normalizing, annealing, quenching and tempering. Heat treatment can change the internal structure of steel, thereby improving its performance and quality. For example, 45 steel can achieve higher hardness and better toughness after quenching and tempering.

Annealing: heating to about 820-840℃, slow cooling, reduced hardness, easy processing.

Normalizing: heating to about 850-870℃, air cooling, grain refinement, improved strength and toughness.

Quenching: heating to about 820-860℃, water cooling or oil cooling, significantly improved hardness.

Tempering: heating to 150-600℃ after quenching, reducing brittleness, adjusting hardness and toughness.

Processing Performance:

Cutting performance: medium, good cutting performance without heat treatment, increased hardness after heat treatment, and increased cutting difficulty.

Welding performance: poor, preheating and post-weld heat treatment are required to avoid cracks.

Forging performance: good, suitable for hot forging.

No. 45 steel is a medium carbon steel with high hardness and strength, but also low toughness. It has good cutting performance and relatively low price, so it is an economical engineering material. After heat treatment, it can obtain higher hardness and better wear resistance. For example, it can be used to make mechanical parts such as shafts, gears, pins, connecting rods, nuts and bolts. In addition, it can be used to make tools such as molds. In the construction field, No. 45 steel can be used to manufacture building structural parts and brackets.

Why Choose 45 Material Steel?

Superior Strength and Hardness: #45 material steel has excellent tensile strength and hardness, making it an ideal choice for parts subject to high stress and wear.

Excellent Machinability: #45 steel has good machinability and is easier to form and manufacture than high-carbon steel.

Cost-Effective Solution: 45 steel offers the best balance between performance and price, making it a cost-effective choice for various applications.

Wide Range of Applications: From gears and shafts to bolts and connecting rods, 45 steel is used in a wide range of industries, including automotive, machinery, and construction.

In Conclusion:

In short, No. 45 steel is a commonly used carbon steel with good hardness and wear resistance and a relatively low price, so it is widely used in machinery manufacturing, construction, tools and other fields. Knowledge of its composition, manufacturing process, performance characteristics, application fields, and heat treatment will help to make better use of this material.

I hope you can consider us if you are looking for a 45 steel supplier. Our company has been engaged in this metal industry for more than ten years.