Hot Rolled Automotive Steel Suppliers

Hot Rolled Automotive Steel Price, please free to contact us.

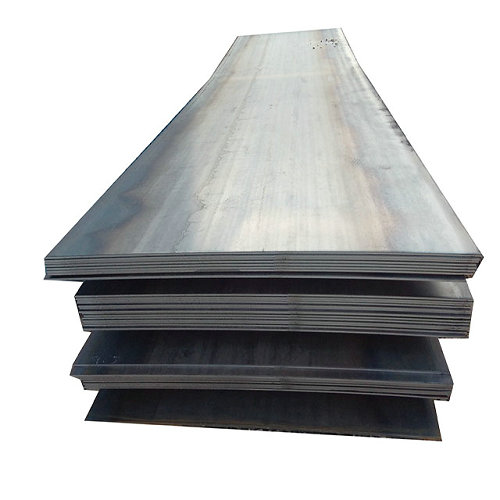

Hot Rolled Automotive Steel

Hot Rolled automotive steel is mainly divided into automobile beam steel, automobile structural steel, automobile compartment steel automobile wheel steel, vehicle pipe structural steel, etc. After feedback from customers, Huaxiao’s products have a good cold working formability and can meet various processing requirements such as shearing, slitting and slitting, stamping, bending, roll welding, and so on.

As one of the few enterprises in China that can stably produce and supply extremely thin and wide specifications, we can stably supply the limit specifications of 1.2*1250mm,2.0*1610mm, and 3.0*1800mm with steel for car compartments, which is the first choice of lightweight materials for commercial vehicles.

For more information on automotive grade sheet metal, contact Huaxiao Metal Steel.

Hot Rolled Automotive Steel Data Sheet

Main Automotive Steel Grades and Strength

Grade | Lower yield strength | Tensile strength | Elongation after fracture | Cold bending test | Low temperature impact test | ||

|

Rel MPa |

Rm, MPa |

A80%, h< 3.0mm |

A%, h≥ 3.0mm |

180°, b=35mm | Test temperature ℃ | Impact-absorbing energy J |

LG510L | ≥355 | 510~ 650 | ≥20 | ≥24 | d=0.5a,Qualified |

– |

– |

LG550L | ≥420 | 550~ 700 | ≥19 | ≥23 | d=a,Qualified |

– |

– |

LG590L | ≥460 | 590~ 740 | ≥17 | ≥20 | d=a,Qualified | -40 | ≥27 |

LG610L | ≥500 | 610~ 760 | ≥15 | ≥18 | d=1.5a,Qualified | -40 | ≥27 |

LG650L | ≥550 | 650~ 820 | ≥13 | ≥16 | d=1.5a,Qualified | -40 | ≥27 |

LG700L | ≥600 | 700~ 880 | ≥12 | ≥14 | d=2a,Qualified | -20 | ≥34 |

LG750L | ≥650 | 750~ 950 | ≥11 | ≥13 | d=2a,Qualified | -20 | ≥34 |

LG800L | ≥700 | 800~ 1000 | ≥10 | ≥12 | d=2a,Qualified | -20 | ≥34 |

LG850LE | ≥800 | >850 | ≥10 | ≥12 | d=3a,Qualified | -40 | ≥27 |

LG980LE | ≥900 | ≥980 |

– | ≥12 | d=4a,Qualified | -40 | ≥27 |

Note:1)a is the thickness of sample;b is the width of bending sample; d is the diameter of bending core. (2)The direction of the tensile test sample is transverse, i.e.P5 sample according to GB/T 228. The direction of the bending sample is transverse, i.e the flapping test according to GB/T 232. the impact powder is longitudinal (i.e parallel to the rolling direction). 3)when the yield is not obvious, use Rp0.2 instead of ReL. 4)For steel with yield strength ≥600MPa, thickness higher than 8mm, the min yield strength can be reduced by 20MPa. | |||||||

Common Structural Steel

Grade | Tensile strength, MPa | Elongation, % | 180° Bending property | |||||

L0=50mm | Longitudinal | |||||||

1.6mm | 1.6-2.0 | 2.0-2.5 | 2.5-3.2 | 3.2 | 3.2 | 3.2 | ||

SPHC-PO | ≥270 | ≥27 | ≥29 | ≥29 | ≥29 | ≥31 | d=0a | d=1a |

SPHD-PO | ≥270 | ≥30 | ≥32 | ≥33 | ≥35 | ≥37 | – | – |

SPHE-PO | ≥270 | ≥32 | ≥34 | ≥35 | ≥37 | ≥39 | – | – |

SPHF-PO | ≥270 | ≥37 | ≥38 | ≥39 | ≥39 | ≥40 | – | – |

Note:the product should be used as soon as possible due to its aging effect. | ||||||||

a) Longitudinal sample should be used for tensile test, i.e P14 sample in GB/T 228.1;b)the property guarantee period is 6 months. | ||||||||

Mechanical Property

Steel grades | Stretching direction | Yield strength MPa | Tensile strength MPa | Elongation A5% | 180° Cold bending b=35mm |

mm |

LG600XT | Transverse | ≥550 | ≥600 | ≥17 | d=2a | 1.2~ 14.0 ×1000~2000 |

LG700XL | Transverse | ≥620 | ≥700 | ≥17 | d=2a | 1.5~ 16.0 ×1000~2000 |

LG750XT | Transverse | ≥700 | ≥750 | ≥15 | d=2a | 2.0~ 14.0 ×1000~2000 |

LG850XT | Transverse | ≥800 | ≥850 | ≥15 | d=2a | 3.0~8.0 ×1000~2000 |

LG900XT | Transverse | ≥850 | ≥900 | ≥15 | d=3a | 3.0~8.0 ×1000~2000 |

note:1、a is sample thickness, b is the width of the cold bending sample, d is the bending diameter. | ||||||