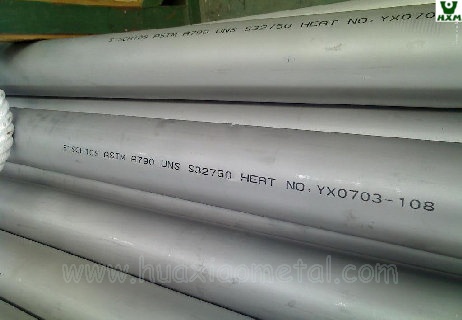

ASTM A790/790M Duplex Steel Seamless Pipe Manufacturer

Huaxiao Metal is your trusted supplier of high-quality ASTM A790/A790M Duplex Steel Seamless Pipes. Our Duplex Steel Pipes are carefully crafted to provide superior strength, excellent corrosion resistance, and long-lasting durability, making them ideal for the most challenging environments. Whether you are in the petrochemical, power generation, or desalination industries, our seamless pipes are designed to meet the highest standards of quality and reliability.

Choose Huaxiao Metal and believe that our ASTM A790/A790M Duplex Steel Seamless Pipes will support your project.

ASTM A790/790M Pipes

Standard: ASTM A790/790M

Material/Steel Grade: S31803, S32205, S32750

Application: Seamless Duplex Stainless Steel Tubing for General Service

Size: OD: 3/4″~10″ WT: SCH5S~SCH80S

Finish: Mill

Duplex Stainless Steel Pipe Specification

| Standard Item |

ASTM A789 | ASTM A790 | EN 10216-5 | |||

|

Grade |

S31803 S32205 S32750 | S31803 S32205 S32750 | 1.4301 1.4307 1.4948 1.4315 1.4401 1.4404 1.4571 1.4541 1.4941 1.4845 1.4449 1.4438 1.4550 1.4912 1.4462 1.4410 |

|||

| Yield Strength (Mpa) |

≥450;≥485;≥550 | ≥450;≥450;≥550 | — | |||

| Tensile Strength (Mpa) |

≥620;≥655;≥800 | ≥620;≥655;≥800 | — | |||

| Elongation(%) | ≥25;≥25;≥15 | ≥25;≥25;≥15 | — | |||

|

Hydrostatic Test |

The Hydrostatic Test shall be in accordance with ASTM A1016.

Could be replaced by ECT. |

The Hydrostatic Test shall be in accordance with ASTM A999.

Could be replaced by ECT. |

The hydrostatic test shall be carried out at a test pressure of 7MPa or at a test pressure calculated using the following formula P=2St/D S=70%Rp0.2 |

|||

| Intergranular Corrosion Test | Usually, use Pitting Corrosion Test. | Usually, use Pitting Corrosion Test. | EN ISO 3651-2 (Optional) | |||

| Eddy Current Test | Could be replaced by HT. | Could be replaced by HT. | EN 10246-3 | |||

|

O.D. Tolerance |

O.D. | O.D.Tolerance | O.D. | O.D.Tolerance | O.D. Tolerance Class | |

| D<12.7 | +/-0.13 | 10.3≤D≤48.3 | +0.40/-0.80 | D3 | +/-0.75% or +/-0.3mm |

|

| 12.7≤D<38.1 | +/-0.13 | 48.3<D≤114.3 | +0.80/-0.80 | |||

| whichever is the greater | ||||||

| 38.1≤D<88.9 | +/-0.25 | 114.3<D≤219.1 | +1.60/-0.80 | D4 | +/-0.5% or +/-0.1mm |

|

| 88.9≤D<139.7 | +/-0.38 | 219.1<D≤457.0 | +2.40/-0.80 | |||

| whichever is the greater | ||||||

|

W.T. Tolerance |

O.D. | W.T.Tolerance | O.D. | W.T.Tolerance | W.T. Tolerance Class | |

| D<12.7 | +/-15% | 10.3≤D≤73.0 | +20.0%/-12.5% | T3 | +/-10% or +/-0.2mm |

|

| 12.7≤D<38.1 | +/-10% | |||||

| 88.9≤D≤457.0 t/D ≤5% |

+22.5%/-12.5% | whichever is the greater | ||||

| 38.1≤D<88.9 | +/-10% | T4 | +/-7.5% or +/-0.15mm |

|||

| 88.9≤D≤457.0 t/D >5% |

+15.0%/-12.5% | |||||

| 88.9≤D<139.7 | +/-10% | |||||

| whichever is the greater | ||||||

What Is ASTM A790/ A790M Standard Seamless Pipe?

ASTM A790/A790M is a standard specification for seamless and welded ferritic/austenitic stainless steel pipes, commonly referred to as duplex stainless steel pipes. These pipes are designed for general corrosive service, with a particular emphasis on their resistance to stress corrosion cracking and pitting.

Features

-

Material Composition: The standard covers duplex stainless steel, which is characterized by a balanced microstructure of austenite and ferrite. This composition offers superior mechanical properties and corrosion resistance compared to standard austenitic stainless steels.

-

Seamless and Welded: The specification includes both seamless and welded pipes, offering flexibility in manufacturing and application.

-

Corrosion Resistance: Duplex stainless steel pipes under this specification exhibit excellent resistance to a wide range of corrosive environments, including chlorides and sulfides, making them ideal for use in harsh conditions.

-

Mechanical Properties: The duplex structure provides high strength and good impact toughness, which is advantageous in many industrial applications.

Applications

ASTM A790/A790M standard pipes are used in a variety of industries due to their robustness and corrosion resistance. Common applications include:

- Chemical Processing: Handling corrosive chemicals and solvents.

- Oil and Gas: Offshore and onshore environments, particularly where resistance to stress corrosion cracking is essential.

- Petrochemical: Piping systems exposed to harsh chemicals and high temperatures.

- Marine: Equipment exposed to seawater and marine atmospheres.

- Pulp and Paper: Process piping exposed to corrosive chemicals.

Benefits of ASTM A790/A790M Pipes

- High Strength: The duplex structure offers higher yield strength compared to austenitic stainless steels.

- Excellent Corrosion Resistance: Suitable for environments where pitting and crevice corrosion are concerns.

- Versatility: Available in both seamless and welded forms, catering to various industrial needs.

- Durability: Long service life due to the superior mechanical properties and corrosion resistance.

Contact Shanghai Huaxiao's ASTM A790/790M Duplex Steel Seamless Pipe

Whether you’re looking for ASTM A790/790M Duplex Steel Seamless Pipe Suppliers, we’ve got you covered. Contact us today to learn more about our ASTM A790 / A790M seamless pipe prices!