Aluminium Metal Suppliers | Manufacturers

Trusted aluminum solutions for your business needs

Reliable delivery of high-quality aluminum sheet/coil/strip/tube/wire/bar

Looking for a reliable aluminium metal supplier with a vast inventory of high-quality products? You’ve come to the right place. Our team of experienced aluminium suppliers offers an extensive range of coils, sheets, strips, tubes, bars, wires, and other products, all sourced from trusted suppliers around the world. With a massive inventory of products available, we can quickly fulfill your order, no matter how large or small. We are the go-to choice for businesses seeking the best in aluminium manufacturers. Read on to learn more about our exceptional products and inventory strength.

Are you looking for aluminium suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Aluminum Metal For Sale From China Aluminium Metal Suppliers

Aluminum Products

Are you looking for aluminium suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Table of Contents

Aluminum Material Characteristics

The following are some common aluminum alloy materials and their characteristics:

Pure Aluminum (Aluminum 1100):

- Good workability: Pure aluminum is extremely workable and is easy to bend, cut, and form.

- Superior electrical conductivity: Pure aluminum is a highly conductive material and is commonly used in wires and cables.

Aluminum Alloy 6061:

- High Strength: 6061 aluminum alloy has high strength and is suitable for applications that require resistance to bending and twisting.

- Corrosion resistance: It has relatively good corrosion resistance and is suitable for outdoor applications.

- Good welding performance: easy to weld and process, suitable for manufacturing various parts and structures.

Aluminum Alloy 5052:

- Good corrosion resistance: 5052 alloy performs well in marine environments and is often used in ship components.

- High plasticity: It has excellent plasticity and is suitable for manufacturing thin plates and special-shaped parts.

- Moderate Strength: The balance of strength and plasticity makes it suitable for a variety of applications.

Aluminum Alloy 7075:

- Extremely high strength: 7075 alloy is the strongest of the aluminum alloys and is commonly used in aviation and aerospace applications.

- Excellent fatigue strength: It exhibits excellent resistance to fatigue stress.

- Wear resistance: Suitable for manufacturing high-load parts such as aircraft parts and bicycle frames.

Aluminum Alloy 2024:

- High Strength and Stiffness: The 2024 alloy offers superior strength and stiffness, making it suitable for structural applications.

- Good processability: Easy to cut, mill, and form.

- Fatigue resistance: suitable for the manufacture of parts that need to withstand vibration and cyclic stress.

These are some common aluminum alloy materials and their characteristics. Different alloys can be selected according to specific needs to meet the requirements of different applications.

Why choose us as your Aluminium Suppliers

Huaxiao is China Aluminium Suppliers

Our Company is located in Shanghai, China, Huaxiao is a full-service aluminum metal supplier and manufacturer that can cater to your needs. Our aluminum metal inventory includes a variety of shapes and a variety of alloys. We offer the following advantages:

- 7-20 days delivery

- Experienced export team

- Custom cut-to-size metal production

- ISO 9001 certification

- Our extensive aluminum inventory is available in a variety of shapes and alloys and is available in full size.

- Aluminum is a silvery, low-density metal used in a variety of commercial applications.

- Unalloyed aluminum is ductile, has moderate strength, and is very resistant to corrosion in most cases.

- Aluminum can be significantly strengthened by the addition of appropriate alloying elements (Cu, Mg, Mn, Si, etc.) and subsequent heat treatment/processing.

- It is usually available in forged and cast forms.

- The metal’s low density makes it widely used in the aerospace industry and other transportation fields. Its corrosion resistance allows it to be used in food and chemical handling (cookware, pressure vessels, etc.) as well as in construction.

- Huaxiao Metal offers a variety of shapes and grades of aluminum metal that can be cut to the size you need, including 1100, 2011, 2024, 3003, 4017, 5052, 6061, 6063, 7075, etc.

- Send us your aluminum requirements directly and we’ll arrange for a colleague to quote you today as soon as possible.

Are you looking for aluminium suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Quality

Adopt international standards for production, use high-quality raw materials, adopt advanced production technology, etc. At the same time, we can provide relevant certification and qualification certificates, such as ISO9001, ISO14001, SGS, etc., to prove that our product quality is reliable.

Experience

We have more than 10 years of experience in aluminum manufacturing and trading and have established long-term cooperative relationships with world-renowned companies. We have a professional team who are familiar with the production process, surface treatment technology, and application scenarios of various aluminum materials, and can provide customers with professional consulting and customized services. We have accumulated rich experience in aluminum manufacturing and trading and can help customers meet various needs and challenges. We are your reliable aluminium supplier.

Are you looking for aluminium suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Customization

We have a professional technical team and advanced processing equipment to provide personalized aluminum processing and customization services for customers. We can customize aluminum products with different shapes, sizes, thicknesses, and surface treatments according to customers’ specific needs and requirements to meet various application demands. We can also provide one-stop services from design to production to ensure product quality and delivery time. Whether it is an individual customer or a large enterprise customer, we can provide satisfactory customization services to help them achieve more efficient and high-quality aluminum applications.

Price and Copetitiveness:

We are customer-centric, and provide customers with the most competitive price and the highest quality aluminum products by optimizing the supply chain, improving production efficiency and independent research and development. We continue to reduce costs and improve efficiency to create greater value for customers.

Are you looking for aluminium suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Reliability and Delivery Time

We are well aware of the urgent needs of customers and the importance of delivery time, and are committed to providing the most reliable supply service. We have formulated a scientific production plan and logistics management plan, strictly control product quality, and ensure to provide customers with stable, accurate and timely delivery services in the shortest possible time. Whether it is a small batch order or a large purchase, we can meet the needs of customers and win their trust and support.

Aluminum Metal is one of the most popular metals in the world. Of all metals, aluminum alloys are the easiest to form and process and are widely used in various industries around the world. Depending on the application and environment, aluminum steel metal has the requirements of the application and is available in various grades and surface finishes.

Whether you are in the market for aluminum coils, bars, plates, pipes, wire rods, or strips, Huaxiao is one of the most trusted aluminium suppliers and distributors in China. We offer 1000, 2000, 300, 4000, 5000, 6000, and 7000 series aluminum metal at competitive prices.

Are you looking for aluminium manufacturers?

REQUEST A QUOTE FOR MORE DETAILS

The FAQ of Aluminium Product

Aluminum Metal Properties

Huaxiao Metal is one of your trusted aluminium suppliers and distributors. Aluminum metal has low density, non-toxicity, high thermal conductivity, good corrosion resistance, and is easy to cast, process, and shape. It is also non-magnetic and non-sparking. It is the second most ductile metal and the sixth most ductile metal.

How aluminium is made?

Aluminum is made through a process called electrolysis. The process involves passing an electric current through a solution of alumina in a molten cryolite solvent. The current separates the oxygen from the alumina, which results in the formation of aluminum at the negative electrode.

The alumina used in the process is extracted from bauxite, which is mined from the earth and then processed into alumina. The alumina is then transported to the aluminum smelting plant, where it is mixed with the cryolite solvent and heated to a temperature of around 950 degrees Celsius.

The electric current is then passed through the mixture, causing the aluminum to be extracted at the negative electrode. The extracted aluminum is then collected and further processed into the desired shape and size, such as sheets, rods, and extrusions.

Overall, the process of making aluminum is complex and energy-intensive, but it results in a lightweight, strong, and durable metal that has a wide range of applications in various industries.

Are you looking for aluminum manufacturers?

REQUEST A QUOTE FOR MORE DETAILS

Advantages of Aluminum Steel

Huaxiao is a direct aluminum supplier and manufacturer of high-quality hot-rolled and cold-rolled aluminum bars, pipes, wires, plates, and coils. Aluminium Suppliers are manufactured to exacting standards to provide the absolute best features and benefits, including:

Light Weight

Aluminum metal is a very light metal with a specific gravity of 2.7 g/cm3, about one-third that of steel. This reduces the manufacturing cost of aluminum metal. Likewise, its use in vehicles reduces dead weight and energy consumption while increasing load capacity. This also reduces noise and improves comfort.

Its strength can be adapted to the desired application by changing the composition of its alloy. Al-Mg-Mn alloys offer the best combination of formability and strength, while Al-Mg-Silicon alloys are ideal for automotive body panels, exhibiting good age hardening when subjected to the paint bake process.

Corrosion Resistance

Aluminum steel naturally develops a protective thin oxide coating that prevents further contact of the metal with the environment. It is especially suitable for applications exposed to corrosive agents, such as kitchen cabinets and vehicles. Generally speaking, the corrosion resistance of aluminum alloy is worse than that of pure aluminum, except for marine magnesium-aluminum alloy. Different types of surface treatments, such as anodizing, painting, or painting, can further improve this characteristic.

Electrical and Thermal Conductivity

Aluminum metal is an excellent conductor of heat and electricity, and for its weight, it conducts electricity almost twice as well as copper. This makes aluminum the first choice for major transmission lines. It is also an excellent heat sink for many applications that require rapid cooling, such as computer motherboards and LED lights.

Reflectivity

Aluminum metal is a good reflector of visible light and heat, which, combined with its low weight, makes it an ideal material for reflectors such as lighting fixtures or rescue blankets. Cool roofs made of coated aluminum steel are invaluable in reducing solar heat gain inside homes by reflecting up to 95% of sunlight.

Ductility

Aluminum metal is malleable and has a low melting point and low density. It can be processed in a variety of ways in the molten state. Its malleability allows aluminum products to be shaped near the end of the product design. Whether it’s the sheet, foil, geometry, tube, rod, or wire, aluminum can do the job.

Low-Temperature Strength

Aluminum steel exhibits a higher tensile strength as the temperature drops compared to steel, which rapidly becomes brittle at low temperatures.

Impermeable and Odorless

The aluminum foil is only 0.007mm thick yet is still durable and completely impermeable, making any food wrapped within it devoid of external taste or odor. It also blocks UV rays. In addition, the metal itself is non-toxic and odorless, making it ideal for packaging sensitive products such as food or pharmaceuticals. The fact that recycled aluminum metal can be used also reduces the carbon footprint of food and beverage manufacturers at this stage.

Non-Magnetic

Aluminum steel is non-magnetic, so it can be used for electronic shieldings, such as computer disks, dish antennas, bus bars, or magnet housings.

Recyclability

Aluminum metal is 100% recyclable, and recycled aluminum steel is the same as the original product. This makes it a more cost-effective source material for production runs. The remelting of aluminum requires very little energy: only about 5% of the energy required to originally produce the virgin metal is required in the recycling process.

Other Service

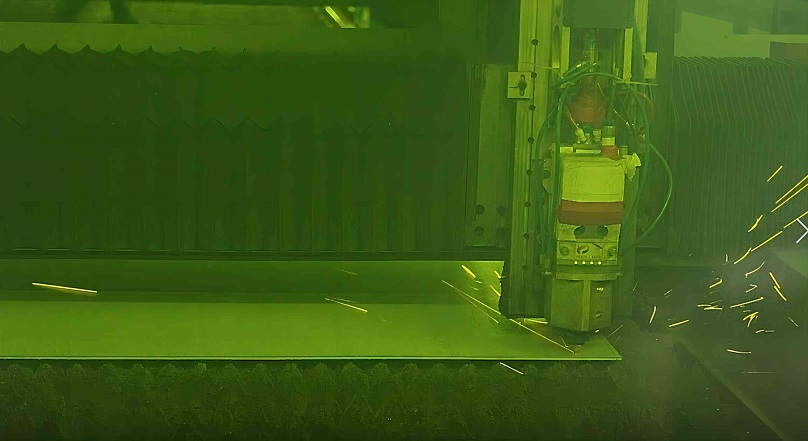

When you order from Huaxiao Metal, we can cut the metal for you according to your size requirements. If you require more extensive service than normal steel, we also offer the following advanced metal-cutting options:

- laser cutting

- water jet cutting

Are you looking for the aluminum factory?

REQUEST A QUOTE FOR MORE DETAILS

Disadvantages of Aluminum Metal

- Softness: Aluminum is a relatively soft metal compared to other metals, such as steel, which means it may be more susceptible to scratches, dents, and other forms of damage.

- Lower strength: While aluminum has a good strength-to-weight ratio, it is generally less strong than steel and other metals, which means it may not be suitable for certain high-stress applications.

- Higher cost: Aluminum is generally more expensive than other metals, such as steel and copper, which may make it less attractive for some cost-sensitive applications.

- Lower melting point: Aluminum has a lower melting point than many other metals, which means it may not be suitable for high-temperature applications.

- Galvanic corrosion: When aluminum is in contact with certain other metals, such as copper and steel, it may experience galvanic corrosion, which can cause the metal to deteriorate over time.

- Despite these disadvantages, aluminum remains a popular and useful metal in many applications, especially in industries such as aerospace, automotive, and construction.

Aluminum vs Stainless Steel

Aluminum and stainless steel are two popular materials used in various industries. While aluminum is lightweight and corrosion-resistant, stainless steel is strong and durable. When choosing between the two, consider factors such as cost, weight, strength, and corrosion resistance. Both materials have their advantages and disadvantages, so it’s important to weigh your options and choose the one that best fits your specific needs.

If you want to know what’s better aluminum or stainless steel. The answer to whether aluminum or stainless steel is better depends on the specific application and needs. Aluminum is lightweight, corrosion-resistant, and easy to work with, while stainless steel is strong, durable, and has a higher melting point. When choosing between the two, it’s important to consider factors such as cost, weight, strength, and corrosion resistance. Ultimately, the best choice will depend on the specific needs of the project or application.

Contact Shanghai Huaxiao's Aluminum Metal Industrial Metal Supply now

Whether you’re looking for aluminum tubes, sheets, or any other shape, we’ve got you covered. Contact us today to learn more about our aluminum steel prices!