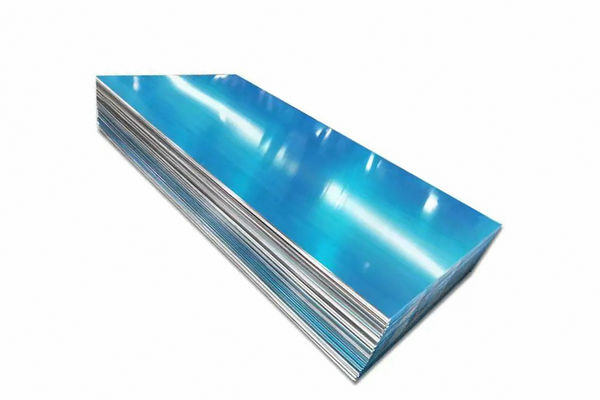

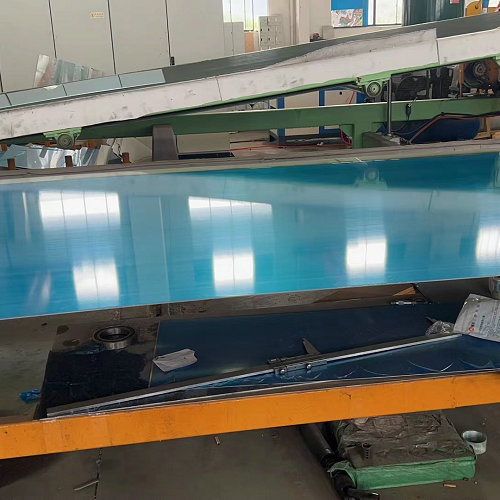

Quality Aluminium Sheet Suppliers in China

Welcome to Hxiao Metal, your reliable supplier of high-quality aluminum sheets! We specialize in metal manufacturing and exporting, providing superior aluminum sheet products to customers worldwide. Whether you are looking for high-quality aluminum plates for construction, aerospace, transportation, or electronic equipment, we have what you need.

Whether you need 6061-T6, 3003-H14, or other alloy aluminum plates, we can provide you with the most suitable products. Choosing Hxiao Metal as your aluminum plate supplier means choosing reliability, quality, and professional service. No matter where you are, we are committed to providing you with all-round support to ensure your project runs smoothly.

Contact us now and let us start the journey of cooperation with high-quality aluminum sheets!

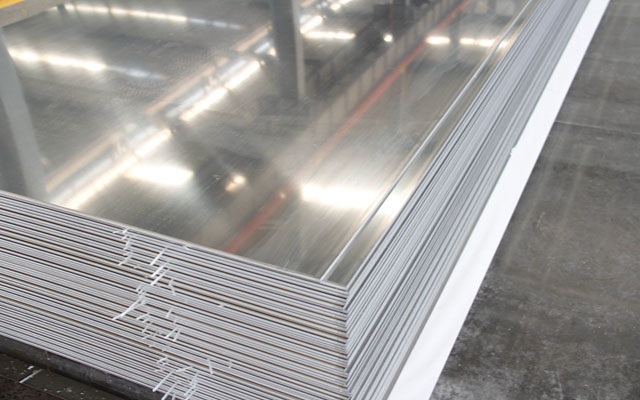

Aluminium Sheet Specification

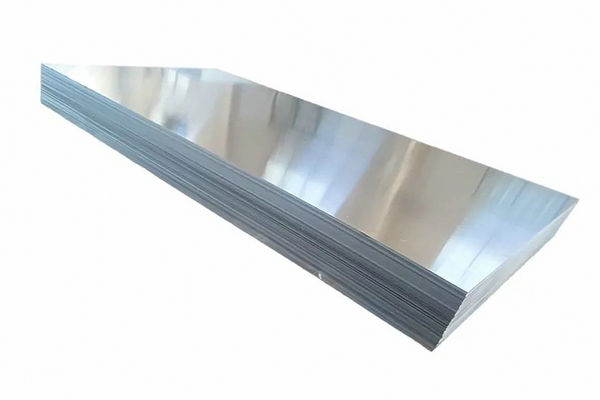

As an aluminium sheet supplier, Huaxiao Metal Co., Ltd. take pride in providing high-quality aluminum sheet products to our customers. The following are the aluminum sheet specifications we can provide.

- Grades: Aluminum sheets are available in different alloys, such as 1100, 3003, 5052, 6061, and 7075, etc, each with unique properties suitable for different applications.

- Thickness: 0.1mm – 30mm

- Width and length: Aluminum sheets are available in different widths and lengths, ranging from a few millimeters to several meters.

- Surface finish: Aluminum sheets can be finished in various ways, including mill finish, anodized finish, brushed finish, and painted finish.

- Temper: Aluminum sheets are also available in different tempers, such as O, H14, H16, H18, and H32, which indicate the level of hardness and strength.

6063 Aluminum Sheet

6063 Aluminum Sheet Suppliers | Manufacturer | Factory Welcome to Huaxiao Metal Company, you deserve the best quality 6063 aluminum sheet products! Aluminum alloy 6063

5454 Aluminum Sheet

5454 Aluminum Sheet Suppliers | Manufacturer | Factory Welcome to Huaxiao Metal Company, you deserve the best quality 5454 aluminum sheet products! Aluminum alloy 5454

1100 Aluminum Sheet

1100 Aluminum Sheet Suppliers | Manufacturer | Factory Welcome to Huaxiao Metal Company, you deserve the best quality 1100 aluminum sheet products! 1100 aluminum sheet/plate

5052 Aluminum Sheet

5052 Aluminum Sheet Suppliers | Manufacturer | Factory Welcome to Huaxiao Metal Company, you deserve the best quality 5052 aluminum sheet products! 5052 aluminum sheet

Table of Contents

Why Choose Huaxiao As Your Aluminium Sheet Suppliers

As an aluminium sheet supplier, we at Huaxiao Metal Corporation Limited take great pride in providing high-quality aluminum sheet products to our customers. Here are some reasons why we believe you should choose us as your aluminium sheet supplier:

- Wide range of aluminium sheet products: As an experienced aluminum sheet supplier, we offer a wide range of aluminum sheet products to meet the diverse needs of our customers. We provide various alloys, sizes, and thicknesses of aluminum sheets to ensure that our customers can find the products they need.

- High-quality aluminum sheet products: We have strict quality control procedures in place to ensure that our aluminum sheet products meet the required quality standards. We have advanced equipment and technology to produce high-quality aluminum sheets.

- Competitive pricing: We offer competitive pricing for our aluminum sheet products without compromising on quality. We strive to offer flexible pricing options to meet the needs and budget of our customers.

- Efficient logistics: We have an efficient logistics system that ensures fast and reliable delivery of aluminum sheet products to our customers. We have a reliable transportation network that ensures timely delivery of products to customers around the world.

- Excellent customer service: We have a team of dedicated professionals who provide excellent customer service. We are always available to answer customer queries, offer technical support, and provide after-sales service.

Other Types of Aluminium Sheets

Perforated Aluminum Sheets

Perforated aluminum sheets are thin, flat pieces of aluminum that have been punched with a pattern of holes. These sheets are used in a variety of applications where a combination of strength, durability, and ventilation is required. They are commonly used in architecture and construction for building facades, sunscreens, and decorative elements, as well as in industrial settings for filtration, soundproofing, and ventilation systems. Perforated aluminum sheets are highly customizable and offer excellent durability and resistance to corrosion.

Aluminium Composite Sheets

Aluminium composite sheets are flat panels made of two thin aluminum sheets bonded to a non-aluminum core. They are strong, lightweight, and durable, making them a popular choice for building facades, signage, and transportation industries. They are highly customizable and available in a range of colors and finishes, and resistant to weathering and corrosion.

Aluminium Anodized Sheets

Aluminium anodized sheets are thin sheets of aluminum that have undergone a process called anodization, which creates a layer of oxide on the surface of the metal. This layer provides enhanced corrosion resistance, durability, and aesthetic appeal to the aluminum sheet. Anodized aluminum sheets are commonly used in architecture, automotive, and electronics industries for their superior properties. They are available in a range of colors and finishes and can be further processed for additional functionality.

Aluminium Checker Plates

Aluminium checker plates, also known as diamond plates, are flat sheets of aluminum with a raised diamond-shaped pattern. This pattern provides increased traction and slip resistance, making them ideal for flooring, stairs, and industrial applications. They are lightweight, durable, and corrosion-resistant, making them suitable for outdoor and indoor use. Commonly used in the transportation industry and for construction and architecture purposes, aluminum checker plates are available in a range of sizes and thicknesses and can be further processed for additional functionality.

Brushed Aluminium Sheets

Brushed aluminium sheets are thin sheets of aluminum that have been given a textured, matte finish through a brushing process. This finish provides a sleek and modern look that is commonly used in architecture and interior design. Brushed aluminum sheets are lightweight, durable, and resistant to corrosion, making them suitable for indoor and outdoor use. They are available in various colors and finishes and can be further processed for additional functionality such as cutting and bending. Brushed aluminum sheets are commonly used in decorative applications like wall cladding, signage, and furniture, as well as in the automotive industry for interior trims and accents.

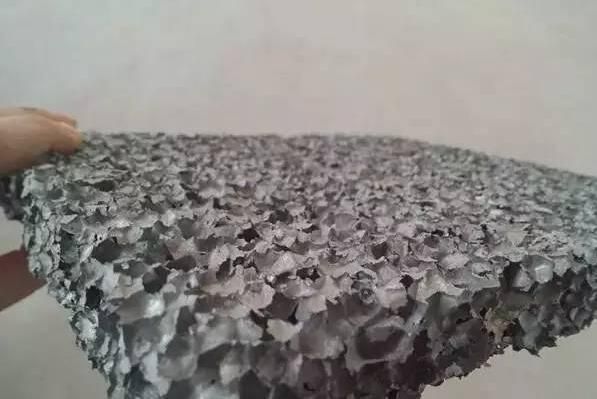

Aluminium Foam Sheets

Aluminum foam sheets are a type of lightweight and porous material made of aluminum that has a cellular structure similar to foam. This unique structure provides excellent energy absorption and acoustic damping properties, making them suitable for a range of applications in the aerospace, automotive, and construction industries.

Aluminum foam sheets can be produced in a range of sizes, shapes, and densities, and are often used for impact and crash protection, noise reduction, and insulation. They are also resistant to fire, corrosion, and electromagnetic interference, making them ideal for use in harsh environments.

Overall, aluminum foam sheets offer a unique combination of lightweight, strength, and energy-absorption properties, making them a valuable material for a variety of applications.

How to Make Aluminium Sheet

The manufacture of aluminum plates usually includes the following steps:

- Smelting and casting of aluminium ingots: First, aluminum ingots are extracted from aluminum ore by smelting bauxite or by electrolysis. Aluminum ingots are then cast into standard sheet forms through a casting process.

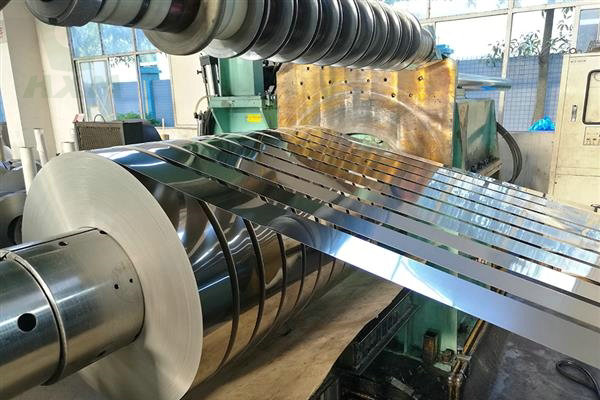

- Heating and Rolling: The aluminum sheet usually needs to be heated to the proper temperature to make it easier to work. Next, the aluminum sheet will be conveyed into a rolling mill where it will be compressed into the desired thickness and width through a rolling process.

- Cold and hot rolling: Aluminum sheets can be cold-rolled or hot-rolled to achieve different surface qualities and mechanical properties. Cold rolling is generally used to produce thinner aluminum sheet, while hot rolling is used to produce thicker aluminum sheets.

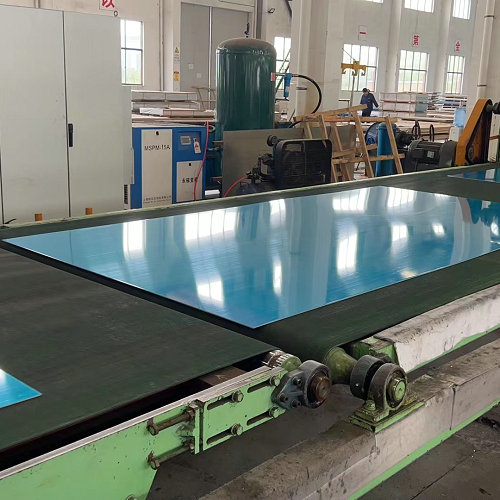

- Shearing and Bending: After rolling, an aluminium sheet usually requires further processing, such as being cut to the desired size or bent into the desired shape.

- Surface treatment: Finally, aluminum panels may require surface treatments such as anodizing, brushing, or painting to improve their corrosion resistance and aesthetics.

Applications of Aluminium Sheets

Aluminum sheets have a wide range of applications in various industries due to their excellent properties, including lightweight, corrosion resistance, good thermal and electrical conductivity, and ease of fabrication. Here are some common applications of aluminum sheets:

- Aerospace: Aluminum sheets are widely used in the aerospace industry to manufacture airplane parts, such as wings, fuselage, and structural components, due to their lightweight and high strength-to-weight ratio.

- Automotive: Aluminum sheets are used in the automotive industry to manufacture parts such as body panels, engine components, and wheels, due to their lightweight and good corrosion resistance.

- Construction: Aluminum sheets are used in the construction industry to manufacture roofing, cladding, and facades, due to their durability, corrosion resistance, and ability to be easily shaped and cut.

- Electronics: Aluminum sheets are used in the electronics industry to manufacture heat sinks, circuit boards, and electrical enclosures, due to their good thermal and electrical conductivity.

- Marine: Aluminum sheets are used in the marine industry to manufacture boat hulls, superstructures, and decks, due to their resistance to corrosion in saltwater environments.

Other Aluminium Metal Products

Perforated Aluminum Sheet

Perforated Aluminum Sheet As one of the Perforated Aluminum Sheet Suppliers with many years of experience in China, we are well aware of customers’ needs

Aluminum Wire

Aluminum Wire For Sale From China Aluminum Wire Supplier Aluminum Wire for Sale As one of the trusted aluminum wire suppliers and manufacturers in China,

Aluminum Pipe

Aluminum Pipe For Sale From China Aluminum Pipe Supplier Aluminum Pipe Suppliers and Manufacturer As one of the trusted aluminum pipe suppliers and manufacturers in

Aluminum Coil

Quality Aluminum Coil Suppliers and Manufacturers Welcome to Hxiao Metal, your trustworthy aluminum coil supplier and manufacturer! We are a company specializing in metal manufacturing

Aluminium Foil

Premium Aluminium Foil Suppliers and Manufacturers Welcome to Hxiao Metal, your trusted aluminum foil supplier and manufacturer! As a company specializing in metal manufacturing and

Aluminum Tread Plate

aluminum tread plate sheet metal As one of the aluminum tread plate suppliers with many years of experience in China, we are well aware of

Aluminum Bar

Aluminum Bar Suppliers | Manufacturer | Factory Welcome to Huaxiao Metal! We are a company with more than ten years of metal manufacturing and export

Aluminum Strip

Aluminum Strip Suppliers and Manufacturers in China Welcome to Huaxiao Metal! As a company with more than ten years of experience in metal manufacturing and

Aluminum Foam

Aluminum Foam Manufacturers Aluminum foam is an excellent material that combines versatility, durability and efficiency. As a leading aluminum foam supplier and manufacturer, Huaxiao Metal

Other Aluminium Sheet Blogs

Advantages of Aluminum Metal Sheet Slitting

What are the benefits of aluminum metal sheet slitting? Why do we need to know these benefits? That’s because the global aluminum market is expanding

Where Can I Buy 4×8 Aluminum Sheets?

Welcome to our website! We are an integrated industry and trade enterprise focusing on the export of aluminum plates, providing high-quality 4×8 aluminum sheets to

How to Cut Aluminum Sheet?

Aluminum sheet is a commonly used metal material widely used in industries, construction and manufacturing. Cutting aluminum sheets is an operation that is often required

How to choose the quenching heating speed of 7075 aluminum plate?

Today, Huaxiao Xiaobian will introduce to you how to choose the quenching heating speed of 7075 aluminum plates. Huaxiao Metal Co., Ltd. is a production

5052 H32 Aluminum Sheet to Colombia

5052 H32 Aluminum Sheet is ideal for most machining techniques as well as interior and exterior applications. 5052 plate is a non-heat-treated product. It is

Aluminum Sheet 5454 h32 to Colombia

Aluminium Sheet 5554 h32 to Colombia Aluminum sheet/plate 5454-H32 is commonly used in fuel, marine, automotive, and machine applications. Compared with 1100 or 3003 aluminum,

Aluminum Sheet 5052 h32 to Colombia

Aluminium Sheet 5052 h32 to Colombia Aluminum sheet/plate 5052-H32 is commonly used in fuel, marine, automotive, and machine applications. Compared with 1100 or 3003 aluminum,

Contact Shanghai Huaxiao's Aluminium Sheet Supplier Now