Quality Aluminum Coil Suppliers and Manufacturers

Welcome to Hxiao Metal, your trustworthy aluminum coil supplier and manufacturer! We are a company specializing in metal manufacturing and exporting, committed to providing superior aluminum coil products to customers worldwide.

Our aluminum coil products offer excellent strength, corrosion resistance, and processability, making them ideal for a variety of applications. Whether you need standard gauge coils or custom-sized aluminum coils, we can meet your needs.

Contact us and choose Hxiao Metal as your aluminum coil supplier!

Aluminum Coil Specification

As one of the aluminum coil suppliers in China, Huaxiao Metal Co., Ltd. takes pride in providing high-quality aluminum coil products to our customers. The following are the aluminum coil specifications we can provide.

- Grades: 1000-8000 series, such as 1100, 3003, 5052, 6061, and 7075, etc, each with unique properties suitable for different applications.

- Thickness: 0.1mm – 30mm

- Width: 500mm-2000mm

- Standard: ASTM AISI JIS DIN GB

- Temper: O – H112

Looking Forward to Becoming One of Your Aluminum Coil Suppliers

Table of Contents

Why Choose Huaxiao As Your Aluminum Coil Suppliers and Manufacturers

As one of the aluminum coil suppliers in China, we at Huaxiao Metal Corporation Limited take great pride in providing high-quality aluminum coil products to our customers. Here are some reasons why we believe you should choose us as your aluminum coil supplier:

- Wide range of aluminum coil products: As an experienced aluminum coil supplier, we offer a wide range of aluminum coil products to meet the diverse needs of our customers. We provide various alloys, sizes, and thicknesses of aluminum coils to ensure that our customers can find the products they need.

- High-quality aluminum coil products: We have strict quality control procedures in place to ensure that our aluminum coil products meet the required quality standards. We have advanced equipment and technology to produce high-quality aluminum coils.

- Competitive pricing: We offer competitive pricing for our aluminum coil products without compromising on quality. We strive to offer flexible pricing options to meet the needs and budgets of our customers.

- Efficient logistics: We have an efficient logistics system that ensures fast and reliable delivery of aluminum coil products to our customers. We have a reliable transportation network that ensures timely delivery of products to customers around the world.

- Excellent customer service: We have a team of dedicated professionals who provide excellent customer service. We are always available to answer customer queries, offer technical support, and provide after-sales service.

Looking Forward to Becoming One of Your Aluminum Coil Distributors

Other Types of Aluminium Coils

Wood Grain Aluminum Trim Coil

Wood grain aluminum trim coil is a specialized type of aluminum coil that is designed to mimic the appearance of wood grain patterns. It is commonly used in construction and architectural applications where a wood-like aesthetic is desired, but the durability and low maintenance of aluminum are preferred.

Pvdf Coated Aluminum Coil

PVDF (Polyvinylidene fluoride) coated aluminum coil is a type of aluminum coil that is coated with a PVDF resin-based paint.

PVDF coated aluminum coil combines the benefits of aluminum’s inherent properties with the exceptional performance and aesthetic possibilities provided by PVDF coatings. It is a popular choice for architectural projects that require durability, weather resistance, and long-lasting color retention.

Looking Forward to Becoming One of Your Aluminum Coil Distributors

Powder Coated Aluminum Coil

Powder coated aluminum coil refers to an aluminum coil that has undergone a powder coating process. In this process, a dry powder paint is applied to the surface of the aluminum coil and then cured under heat to form a durable and protective coating.

Powder coated aluminum coil offers a durable and aesthetically pleasing finish for aluminum surfaces. Its excellent resistance to weathering, wide color options, and low maintenance requirements make it a popular choice in many industries.

PVC Coated Aluminum Coil

PVC coated aluminum coil refers to an aluminum coil that is coated with a layer of PVC (Polyvinyl Chloride) material. The PVC coating provides additional protection and enhances the aesthetic appeal of the aluminum coil.

PVC coated aluminum coil provides an added layer of protection and customization options to aluminum surfaces. Its durability, weather resistance, low maintenance requirements, and aesthetic possibilities make it a popular choice in various industries, particularly in construction and architectural applications.

Looking Forward to Becoming One of Your Aluminum Coil Manufacturers

PE Coated Aluminum Coil

PE coated aluminum coil refers to an aluminum coil that is coated with a layer of PE (Polyester) material.

PE coated aluminum coil provides an added layer of protection, customization options, and improved performance to aluminum surfaces. Its durability, weather resistance, low maintenance requirements, and aesthetic possibilities make it a popular choice in various industries, particularly in construction and architectural applications.

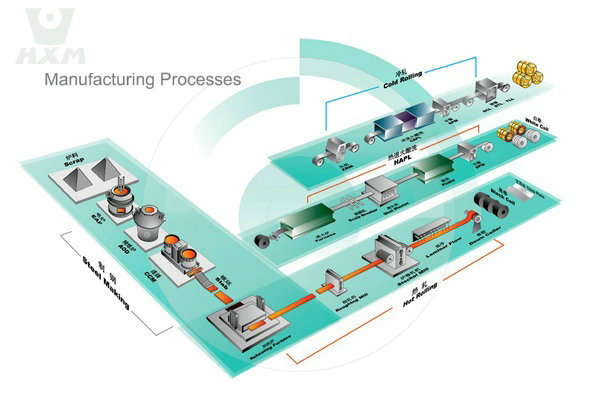

How to Make Aluminium Coil

The process of making aluminum coils involves several steps. Here is a general overview of the manufacturing process:

- 1. Melting and Casting: The first step is melting aluminum scrap or primary aluminum in a furnace. The molten aluminum is then cast into large ingots or billets.

- 2. Homogenization: The ingots or billets are heated and soaked at a controlled temperature to ensure uniformity and remove any internal stresses. This process is known as homogenization.

- 3. Hot Rolling: The homogenized aluminum is passed through a series of hot rolling mills. The metal is gradually reduced in thickness while being heated to a specific temperature. This process elongates and thins the aluminum, forming a continuous strip known as a hot coil.

- 4. Cold Rolling: The hot coil is further processed through cold rolling mills. It is uncoiled and passed through multiple sets of rollers that gradually reduce the thickness to the desired gauge. Cold rolling improves the surface finish, mechanical properties, and dimensional accuracy of the aluminum.

- 5. Annealing: After cold rolling, the aluminum coil may undergo an annealing process. The coil is heated and then slowly cooled to enhance its ductility, eliminate internal stresses, and improve the coil’s workability.

- 6. Surface Treatment: Depending on the intended application, the aluminum coil may undergo surface treatments such as cleaning, chemical treatments, coating, or painting. These treatments improve the coil’s appearance, corrosion resistance, and adhesion properties.

- 7. Slitting: The wide aluminum coil is slit into narrower coils of the desired width using slitting machines. This process allows for customized coil sizes based on customer requirements.

- 8. Recoiling and Packaging: The slit coils are then recoiled, usually onto a core or spool, and packaged for shipping. The packaging is designed to protect the coils during transportation and storage.

Looking Forward to Becoming One of Your Aluminum Coil Suppliers

Applications of Aluminum Coils

Aluminum coils find applications in various industries due to their advantageous properties. Here are some common applications of aluminum coils:

- 1. Construction: Aluminum coils are widely used in the construction industry for roofing, siding, gutters, and facades. They offer lightweight and durable solutions that resist corrosion and provide excellent thermal and electrical conductivity.

- 2. Transportation: Aluminum coils are utilized in the automotive and aerospace industries for manufacturing vehicle bodies, panels, and components. Their low density helps reduce weight, enhancing fuel efficiency and improving overall performance.

- 3. Heat Exchangers: Aluminum coils are employed in heat exchangers for HVAC systems, refrigeration units, and air conditioners. Their high thermal conductivity allows for efficient heat transfer, contributing to energy savings and improved cooling performance.

- 4. Packaging: Aluminum coils are used in the packaging industry for manufacturing foil containers, trays, lids, and closures. Aluminum’s barrier properties ensure food preservation, prevent spoilage, and maintain product freshness.

- 5. Electrical: Aluminum coils are utilized in electrical applications, including transformers, power transmission lines, and electrical cables. They possess excellent electrical conductivity and are lightweight, making them suitable for efficient power distribution.

- 6. Industrial and Manufacturing: Aluminum coils are employed in various industrial and manufacturing processes. They are used in the production of appliances, machinery, and equipment components, thanks to their strength, formability, and resistance to corrosion.

- 7. Marine: Aluminum coils are utilized in the marine industry for building boat hulls, decks, and superstructures. Aluminum’s corrosion resistance, lightweight, and durability make it ideal for marine environments.

- 8. Energy: Aluminum coils are used in renewable energy applications, such as solar panels and wind turbines. Their lightweight nature and ability to withstand harsh weather conditions make them suitable for these applications.

Looking Forward to Becoming One of Your Aluminum Coil Manufacturers

Other Aluminium Metal Products

Contact Shanghai Huaxiao's Aluminum Coil Supplier Now