Aluminum Pipe For Sale From China Aluminum Pipe Supplier

Aluminum Pipe Suppliers and Manufacturer

As one of the trusted aluminum pipe suppliers and manufacturers in China, our delivery time is about 7-25 days, and we supply aluminum tubes with various steel options and sizes. As a professional aluminum pipe supplier, Huaxiao Metal specializes in producing different types of aluminum tubes at competitive prices.

Huaxiao Metal specializes in the production of high-grade aluminum tubes and a variety of products. Contact us today to find out how we can serve your aluminum pipe supplier needs.

Aluminum Pipe Specifications

Shape:

- Round aluminum tube

- Square aluminum tube

- Rectangular aluminum tube

- oval aluminum tube

- Pipe (cylindrical) aluminum tube

- Other custom-shaped aluminum tubes

Temper

- T6 temper (artificial aging after heat treatment): has good strength and mechanical properties, and is usually used for applications requiring higher strength.

- T5 temper (artificial aging treatment): It has good strength and formability and is often used for general applications.

- O state (soft state): lower strength and higher formability, suitable for cold bending and forming.

- Other states, there may be other states according to specific application requirements.

Common Aluminum Alloys:

- 6061 aluminum alloy: has good strength, corrosion resistance, and weldability. Widely used in the field of structure and construction.

- 6063 aluminum alloy: easy to extrude, good surface quality, used in construction and decoration fields.

- 5083 aluminum alloy: has high corrosion resistance and is mainly used in marine and marine applications.

- 7075 aluminum alloy: high strength, often used in aerospace and high-stress applications.

- 3003 aluminum alloy: Medium strength and good corrosion resistance, often used in applications such as HVAC systems.

Dimensions and Standards:

- Outer diameter (OD): Usually expressed in millimeters or inches, such as 25.4mm (1 inch), 50mm, etc.

- Wall thickness: expressed in millimeters or inches, such as 2mm, 3mm, etc.

- Manufactured according to ASTM, EN, and other standards to ensure that it meets the requirements of relevant industry standards.

Length and Customization:

- Standard length: usually 3 meters, 6 meters, etc.

- According to project requirements, aluminum tubes of different lengths can be customized.

Special Coatings and Treatments:

- Anodized: Provides enhanced corrosion resistance and surface hardness.

- Powder Coating: Enhances appearance and weather resistance.

In Huaxiao Metal, we strive to bring customers the best products and value-added services that exceed expectations. We have received satisfactory evaluations from customers in the UK, Germany, Australia, UAE, Canada, Mexico, Brazil, and the United States. Professional dedication and service have made us a leader in the aluminum metal trading industry. We offer a variety of aluminum tubing options to meet your varying needs for all types of applications.

Looking Forward to Becoming One of Your Aluminum Pipe Suppliers

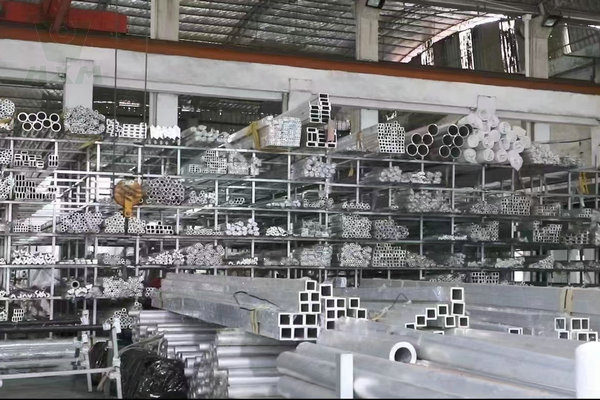

Aluminum Pipe Suppliers and Factory

Huaxiao Metal is a China aluminum pipe manufacturer specializing in designing and producing standard, special, and customized extruded profiles. Find out more about our expertise!

With nearly two decades of export and production experience, our company provides a wide range of high-quality aluminum pipes for various applications. Our product range includes aluminum seamless pipes and aluminum welded pipes.

We have established long-term cooperative relationships with well-known steel mills such as Baosteel, Baotou Steel, Wuhan Iron and Steel, Hegang, Lianyuan Iron and Steel, Rizhao, and Lingyuan to ensure that aluminum pipes meet international standards.

Looking Forward to Becoming One of Your Aluminum Pipe Suppliers

Table of Contents

Classification of Aluminum Pipes

Aluminum pipes can be classified based on various factors, including their shape, manufacturing process, application, and alloy composition. Here are some common classifications of aluminum pipes:

Based on Shape:

Aluminum Round Tubes: These are the most common type of aluminum pipes and are widely used in various industries. They come in a range of diameters and wall thicknesses.

Aluminum Square Tubes: These have a square cross-section and are often used in structural and architectural applications.

Aluminum Rectangular Tubes: These have a rectangular cross-section and are also used in construction and engineering projects.

Aluminum Oval Tubes: These have an oval or elliptical cross-section and are used in applications where aesthetics or specific shapes are desired.

Looking Forward to Becoming One of Your Aluminum Pipe Suppliers

Based on Manufacturing Process:

- Seamless Aluminum Pipes: These are manufactured without any seams, resulting in a smoother internal surface. They are often used in high-pressure and critical applications.

- Welded Aluminum Pipes: These are made by welding aluminum sheets or strips together. They are suitable for less critical applications and are more cost-effective.

Based on Application:

Structural Aluminum Pipes: These are used in construction and architectural applications for framing, support, and load-bearing purposes.

Transportation Aluminum Pipes: Used in the automotive, aerospace, and marine industries for components such as frames, exhaust systems, and boat rails.

Industrial Aluminum Pipes: Used in industrial machinery, equipment, and manufacturing processes for conveying fluids, gases, and materials.

Heat Transfer Aluminum Pipes: Used in heat exchangers, radiators, and HVAC systems for their thermal conductivity properties.

Decorative Aluminum Pipes: Used in furniture, interior design, and artistic projects due to their aesthetic appeal and customizable shapes.

Looking Forward to Becoming One of Your Aluminum Pipe Suppliers

Based on Alloy Composition:

6061 Aluminum Pipes: A versatile alloy with good strength and corrosion resistance. Commonly used in structural and architectural applications.

6063 Aluminum Pipes: Known for its excellent extrudability and surface finish qualities. Used in architectural and decorative applications.

5083 Aluminum Pipes: Offers high corrosion resistance and is commonly used in marine applications due to its resistance to saltwater.

7075 Aluminum Pipes: Has high strength and is used in aerospace and high-stress applications.

3003 Aluminum Pipes: Known for its moderate strength and good corrosion resistance. Used in various applications including HVAC systems.

These are just a few examples of how aluminum pipes can be classified. The specific classification will depend on the intended use, industry standards, and alloy properties required for a particular application. When selecting aluminum pipes, it’s important to consider the specific needs of your project to ensure you choose the most suitable type.

Looking Forward to Becoming One of Your Aluminum Pipe Manufacturers

Aluminum Tube Sizes in Different Shapes

Aluminum tubing can vary in size depending on its shape and use. Here are some examples of different shapes of aluminum tubing sizes:

Aluminum Round Tube:

- Outer diameter (OD): from small to large, usually expressed in millimeters or inches, such as 6mm, 10mm, 25.4mm (1 inch), etc.

- Wall thickness: expressed in millimeters or inches, such as 1mm, 2mm, 3mm, etc.

- Length: Usually standard length, such as 3 meters, or 6 meters, can also be customized according to needs.

Aluminum Square/Rectangular Tube:

- Outer length: expressed in millimeters or inches, such as 20mm x 20mm, 50mm x 25mm, etc.

- all thicknesses: expressed in millimeters or inches, such as 1mm, 1.5mm, 2mm, etc.

- Length: usually standard length, also can be customized according to needs.

Aluminum Oval Tube:

- The major axis and minor axis dimensions of the ellipse: are usually expressed in millimeters or inches, such as 50mm x 30mm, 100mm x 50mm, etc.

- Wall thickness: expressed in millimeters or inches, such as 1mm, 1.5mm, 2mm, etc.

- Length: usually standard length, also can be customized according to needs.

It should be noted that the above dimensions are examples only and do not represent all possible aluminum tube dimensions. The dimensions of aluminum tubing can vary depending on the manufacturer, supplier, market demand and requirements of a particular application. When selecting the size of the aluminum tube, the expected load, use environment, manufacturing process and possible processing needs should be considered. It is best practice to consult with the supplier or manufacturer in detail to obtain information on the size of aluminum tubing that will best suit your project.

Looking Forward to Becoming One of Your Aluminum Pipe Manufacturers

Product Features of Aluminum Tube

Aluminum tubes offer a range of product features that make them desirable for various applications. These features contribute to their popularity in industries such as construction, automotive, aerospace, marine, 3d printing, and more. Here are some key product features of aluminum tubes:

Lightweight: Aluminum is known for its low density, making aluminum tubes significantly lighter than many other materials like steel. This property is particularly advantageous in applications where weight reduction is important.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer that helps prevent corrosion, even in challenging environments. This corrosion resistance is especially valuable in applications where exposure to moisture, chemicals, or saltwater is a concern.

Strength-to-Weight Ratio: Aluminum tubes offer an excellent strength-to-weight ratio, providing good structural integrity while keeping the overall weight of the structure or component low.

Ductility: Aluminum is highly ductile, meaning it can be easily formed, bent, or shaped without cracking or breaking. This property allows for the creation of complex and intricate designs.

Thermal Conductivity: Aluminum has high thermal conductivity, which makes aluminum tubes suitable for applications that involve heat transfer, such as heat exchangers and HVAC systems.

Electrical Conductivity: Aluminum tubes are also electrically conductive, making them useful in applications that require electrical connections or grounding.

Aesthetic Appeal: Aluminum tubes can be finished with various surface treatments, including anodizing, polishing, and painting, to enhance their appearance and match specific design requirements.

Recyclability: Aluminum is highly recyclable without losing its properties. This sustainability aspect is increasingly important in today’s environmentally conscious manufacturing practices.

Non-Magnetic: Aluminum is non-magnetic, which makes aluminum tubes suitable for applications where magnetic interference needs to be minimized, such as in certain medical or scientific equipment.

Wide Range of Alloys: Aluminum tubes are available in a variety of alloys with different properties, allowing for customization based on specific application needs.

Ease of Fabrication: Aluminum tubes are relatively easy to fabricate, cut, weld, and join using various methods, making them versatile for different manufacturing processes.

Low Maintenance: Due to its corrosion resistance and durability, aluminum tubes generally require less maintenance compared to other materials.

Suitable for High-Temperature Applications: Some aluminum alloys, like 6061, retain their strength and structural integrity at elevated temperatures, making them suitable for high-temperature applications.

Cost-Effective: Aluminum tubes often provide a cost-effective solution due to their combination of properties and ease of manufacturing.

It’s important to consider the specific alloy, temper, dimensions, and surface finish of the aluminum tube based on the intended application. Different combinations of these factors can optimize the tube’s performance for the desired use case.

Looking Forward to Becoming One of Your Aluminum Pipe Manufacturers

Why choose us as your Aluminum Pipe Supplier and Manufacturers?

When choosing an aluminum pipe manufacturer, you need to consider many factors, including product quality, price, delivery time, service, etc. The following are our advantages as a aluminum pipe manufacturer, which can be used as the basis for you to choose us:

1. Rich experience: We have many years of experience in the production of aluminum pipes, and have a deep understanding of the production process and technology, which can guarantee the quality and stability of the products.

2. Excellent quality: We produce aluminum pipes in strict accordance with international standards and customer requirements to ensure product performance and quality. We also have a complete quality control system to test and verify each batch of products to ensure product consistency and pass rate.

3. Competitive price: Our price is competitive in the market, while ensuring product quality and service quality, we can provide reasonable prices.

4. Timely delivery: We have an efficient production process and a complete supply chain management system. We have an aluminum steel product inventory of about 1,000 tons throughout the year, which can ensure that orders are completed and delivered on time.

5. Perfect after-sales service: We provide perfect after-sales services such as product quality problem solving and technical support, and provide customers with a full range of services.

To sum up, as one of the aluminum pipe suppliers in China, we have advantages in product quality, price, delivery time, and after-sales service, and can provide customers with satisfactory products and services.

Looking Forward to Becoming One of Your Aluminum Pipe Manufacturers

Huaxiao Aluminum Pipe Export Package

Our company adopts standard export packaging. Most of our customers from the UK, South Korea, Colombia, the United Arab Emirates, and Australia often use this kind of packaging. If customers have other packaging requirements, as aluminum suppliers, we will definitely meet your package requirements.

Welcome your inquiry! We will send you the aluminum pipe price within 24 hours.

Looking Forward to Becoming One of Your Aluminum Pipe Manufacturers

Huaxiao Aluminum Pipe Export Package

how to cut aluminum pipe?

Use a suitable tool, such as a metal cutting saw or angle grinder, equipped with a special aluminum alloy cutting disc. Make sure to secure the aluminum tube while cutting and use lubricant to reduce heat.

How to bend aluminum pipe?

Cold bending method: Use a tube bender, suitable for small angle bending, and control the bending radius to avoid creases.

Hot bending method: Heat to an appropriate temperature (about 300°C or less), then slowly bend with a mold or manually.

How to make aluminum pipe?

Extrusion method: Extruding tubular aluminum through a die, suitable for mass production.

Stretching method: For aluminum tubes with higher precision, first make a hollow billet and then adjust the size by stretching.

How to weld aluminum pipe?

Use TIG welding (tungsten inert gas welding) or MIG welding (metal inert gas welding), and choose suitable aluminum welding wire (such as ER4045). Pay attention to clean the welding surface to avoid oxidation.

Contact Us For China Aluminum Pipe Prices

Welcome your inquiry! We will send you the aluminum pipe prices within 24 hours.