Clad Steel Metal Supplier – Stainless, Copper & Titanium Cladding | Huaxiao Metal

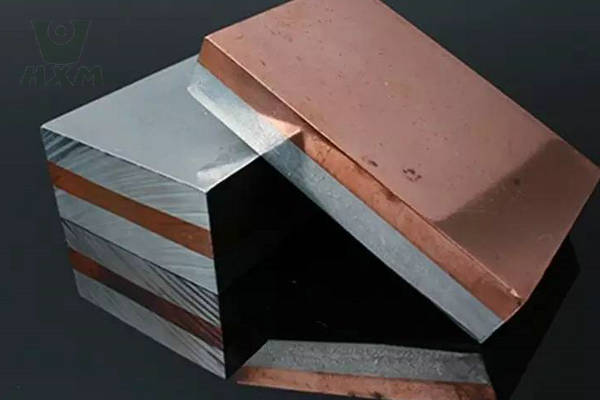

Composite Metal (Clad Steel Metal)is a material made by combining two or more different metal materials through a specific process, aiming to combine the advantages of each material to obtain better comprehensive performance. Composite metal not only has the excellent properties of different metals but also can achieve performance that a single metal material cannot achieve in some special applications.

We are a professional clad steel metal supplier, committed to providing high-performance clad plates, clad pipes, and other clad metal products to customers around the world. Whether you are in the shipbuilding, petrochemical, construction or energy industries, we can provide products that meet your needs. Contact us now to get clad metal prices and stock information!

Are you looking for clad steel suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Clad Steel Metal For Sale From China Composite Metal Suppliers

Huaxiao Metal is your one-stop source for premium clad steel plate products. Whether you need 316L + Q345R clad plates, Ti + CS composite plates, or Ni-based cladding, we’re ready to deliver.

Contact us now for pricing, samples, and technical support!

Stainless Steel Clad Plate:

The stainless steel clad plate is a kind of high-efficiency and energy-saving composite material with carbon steel as the base and stainless steel coated on one or both sides. It can give full play to the characteristics and advantages of the two metal materials. It has corrosion resistance, wear resistance, anti-magnetism, and decorativeness of stainless steel. It also has good weldability, formability, drawability, and thermal conductivity of carbon steel.

This material can save nickel-chromium alloy and reduce manufacturing costs while maintaining strong hardness. Therefore, it can completely or partially replace the use of stainless steel in various industries. It can be widely used in oil refining, petrochemicals, machinery, shipbuilding, salt and alkali making, brewing, water conservancy and hydropower, environmental protection, and other fields, with huge social and economic benefits.

Titanium Composite Plate:

Due to its superior corrosion resistance, titanium is more corrosion resistant than stainless steel or copper alloy in most cases, so it is widely used in various chemical reactors, heat exchangers and other key components with high corrosion resistance requirements. Titanium steel composite plate takes advantage of the high strength of ordinary steel plates and effectively solves the disadvantage of high cost of pure titanium materials. It is widely used in PTA projects, power generation equipment tube plates, marine steel structures and other fields.

Nickel-Based Alloy Composite Plate:

Nickel-based alloy is based on nickel, with other alloy elements added. Its main alloy elements include copper, chromium, molybdenum, niobium, tungsten, etc., such as NiCu alloy, NiCrMO alloy, NiCrFe alloy, etc., which can resist various acid corrosion and stress corrosion and have good comprehensive performance. Nickel-based alloy composite plate is a new type of metal structural material that fully utilizes the characteristics of nickel-based alloy and the high strength of the substrate.

It usually has the characteristics of excellent corrosion resistance, good wear resistance, and good high-temperature resistance. It is widely used in marine engineering, the nuclear industry, monocrystalline silicon, the aerospace industry, the salt industry, the environmental protection field, etc.

Copper Clad Plate:

Pure copper has high electrical and thermal conductivity and good ductility and is a common material for various electronic components and electrical cables. The copper alloy made by adding alloy elements such as zinc, nickel, and zirconium has the characteristics of mechanical wear resistance, corrosion resistance, and strong impact resistance. Copper alloys are new materials that form a strong bond with carbon steel, stainless steel, titanium, etc. through explosion welding.

While maintaining the inherent characteristics of copper and copper alloys, their strength and corrosion resistance are enhanced. They can be widely used in the power industry, metallurgical industry, rail transportation, aerospace, chemical equipment, and other fields.

Aluminum Clad Plate:

Aluminum alloys have the advantages of being lightweight, having good conductivity, high strength, and strong corrosion resistance. They are currently one of the most widely used and cost-effective materials. Usually, aluminum-steel and aluminum-titanium-steel composite plates are used to connect aluminum guide rods and steel claws in the electrolytic aluminum industry.

With the development of marine engineering, rail transportation, clean energy, and other fields in recent years, aluminum-steel and aluminum-titanium-steel clad plates have also been widely used in these new fields, such as connecting the upper aluminum alloy building of marine ships with the steel main hull, LNG vaporizer transition joints, rail transportation induction plates, etc.

Are you looking for clad metal suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Production Process of Composite Metals

There are many production processes for composite steel metals, each of which has its unique characteristics and scope of application. The following are some common clad steel metal production processes:

1. Explosion Welding

Explosion welding is a process that uses the impact force of an explosion to tightly bond two metal materials.

● Steps:

a. Place the metal plates to be bonded in parallel, with the surfaces to be bonded facing each other.

b. Cover the upper metal plate with explosives.

c. Detonate the explosives, and the shock wave generated by the explosion presses the upper metal into the lower metal at high speed, thereby forming a metallurgical bond.

● Advantages:

○ Can bond metal materials of different thicknesses.

○ High bonding strength.

● Disadvantages:

○ Complex process and certain danger.

2. Hot Rolling Clad Plate

Hot rolling clad is to bond two or more metal materials together through a hot rolling process.

● Steps:

a. Surface treat different metal materials to remove oxides and impurities.

b. Stack the metal materials to be bonded together and heat them to an appropriate temperature.

c. Rolling through a hot rolling mill allows the metal materials to be tightly bonded under high temperature and pressure.

● Advantages:

○ Suitable for mass production.

○ High production efficiency.

● Disadvantages:

○ High requirements for temperature and process control.

3. Explosion Rolling Clad Plate

Explosion rolling clad combines the advantages of explosion welding and hot rolling processes.

● Steps:

a. First, preliminary bond different metal materials through explosion welding.

b. Then further improve the bonding strength and plate quality through hot rolling.

● Advantages:

○ High bonding strength, suitable for thick plates.

○ High production efficiency.

● Disadvantages:

○ Complex process and high cost.

4. Brazing

Brazing is a process that uses filler metal to connect different metal materials.

● Steps:

a. Clean the surface of the metal materials to be bonded.

b. Place filler metal between the bonding surfaces.

c. Heat until the filler metal melts and penetrates the bonding surface through capillary action, and forms a bond after cooling.

● Advantages:

○ Applicable to metal parts with complex shapes and small sizes.

○ Simple process and low cost.

● Disadvantages:

○ General bonding strength and limited scope of application.

5. Explosive Bonding in Pressure Vessels

This method is mainly used to manufacture large pressure vessels.

● Steps:

a. Place the inner and outer metal materials together to form a preliminary pressure vessel shape.

b. Place explosives on the inner metal and detonate to form a metallurgical bond.

● Advantages:

○ Applicable to pressure vessels with large sizes and complex shapes.

○ High bonding strength.

● Disadvantages:

○ Complex process and high cost.

6. Powder Metallurgy

Powder metallurgy is a process for forming composite materials by pressing and sintering metal powders.

● Steps:

a. Mix different metal powders evenly.

b. Form a preliminary shape by pressing.

c. Sintering at high temperature to combine metal powders.

● Advantages:

○ Can produce composite materials with complex shapes.

○ High material utilization rate.

● Disadvantages:

○ The manufacturing process is slow and suitable for small-batch production.

Each clad steel metal production process has its specific application scenarios and advantages and disadvantages. The selection of the appropriate process needs to be comprehensively considered based on specific needs and material properties.

Application Fields of Composite Steel Metal

Due to their excellent comprehensive properties, composite metals have been widely used in many fields:

Chemical Equipment:

○ Used for equipment such as storage tanks, reactors, and pipelines that require corrosion resistance and high strength.

Marine Engineering:

○ Used for offshore platforms, ships, and other structural parts that need to be used in seawater for a long time.

Architectural Decoration:

○ Used for structural parts such as building exterior walls and interiors that require beauty and corrosion resistance.

Food Industry:

○ Used for food processing equipment, storage tanks, and other equipment that require hygiene and corrosion resistance.

Aerospace:

○ Used for aircraft, rockets, and other structural parts that require high strength and lightweight.

Electronic Products:

○ Used for shells and parts of mobile phones, laptops, and other devices that require conductivity and durability.

Looking for a reliable clad steel supplier? Contact us for a quick quote or custom fabrication.

Are you looking for clad steel manufacturers?

REQUEST A QUOTE FOR MORE DETAILS

Characteristics of Composite Metals

1. Excellent comprehensive performance: By combining the advantages of different metals, composite metals can provide excellent mechanical strength, corrosion resistance, thermal conductivity, electrical conductivity, etc.

2. Cost saving: The combination of low-cost substrates (such as carbon steel) and thinner high-performance metal layers (such as stainless steel, and titanium) can meet performance requirements and reduce costs.

3. Design flexibility: The combination and thickness of different metal materials can be customized according to specific application requirements to achieve the best balance between performance and cost.

Are you looking for the clad steel factory?

REQUEST A QUOTE FOR MORE DETAILS

Why Choose Our Clad Steel Metal?

✅ One of the leading clad steel plate manufacturers in China

✅ State-of-the-art facilities for explosion bonded steel plate production

✅ ISO & SGS certified processes with 100% material traceability

✅ Exported to 50+ countries with global shipping support

✅ Full technical support, including MTCs, welding guidance, and 3D drawings

As the industry-leading Clad Steel Suppliers, we are committed to providing the highest quality products and the most competitive Clad Steel Prices. Our composite steel not only has excellent mechanical strength and corrosion resistance but is also widely used in many fields such as the chemical industry, construction, food processing, etc.

Whether it is mass production or customized needs, we can provide you with comprehensive solutions. If you are looking for Clad Steel For Sale, please rest assured to choose us, we will provide you with efficient, reliable, and economical composite steel products to help your project go smoothly.

FAQ

What Is Clad Steel?

Clad steel metal combines different metals, usually stainless steel, aluminum, copper, or nickel, with a carbon steel base. It combines the base metal’s strength with the surface metal’s corrosion resistance, making it an important base material for various industries.

Huaxiao Metal produces various types of clad steel using explosion bonding, hot rolling, and solid-state diffusion techniques to ensure excellent bond strength and material integrity.

Do you support custom composite metal combinations?

Yes, we offer full flexibility to match your application needs (e.g., SS + CS, Cu + SS, Ti + Steel).

Can Composite Metals be Welded?

They can be welded, but the appropriate welding process needs to be selected according to the material layers of the composite metal. For example, stainless steel composite plates can be welded by TIG or MIG welding, while nickel-based composite plates may require more professional welding technology.

Can Clad Steel Metal Replace Traditional Stainless Steel?

In many scenarios, clad steel metal provides a more economical solution because it retains the corrosion resistance of stainless steel while reducing costs. Therefore, it is often an ideal substitute in applications such as pressure vessels and storage tanks.

How strong is the corrosion resistance of composite metal?

The corrosion resistance of composite metal depends on the surface metal used. For example, stainless steel and nickel-based materials have very high corrosion resistance and can be used for a long time in seawater and chemical environments.

What is the difference between Clad Metal and Traditional Metal?

Clad metal combines the advantages of several metals, such as corrosion resistance, conductivity and strength, at a lower cost.

Does Huaxiao Metal's composite steel metal comply with international standards?

Yes, our products strictly comply with international standards such as ASTM, ASME, JIS, EN, and relevant certification documents can be provided.

Contact Shanghai Huaxiao Metal

Whether you’re looking for clad steel metal suppliers, we’ve got you covered. Contact us today to learn more about our clad steel prices!