Clad Aluminum Sheet Suppliers and Manufacturers

Huaxiao Meatl offers a range of quality aluminum composite panels suitable for a variety of indoor and outdoor uses. Browse aluminum composite panels in a wide range of colors and order them cut to size to suit your specifications.

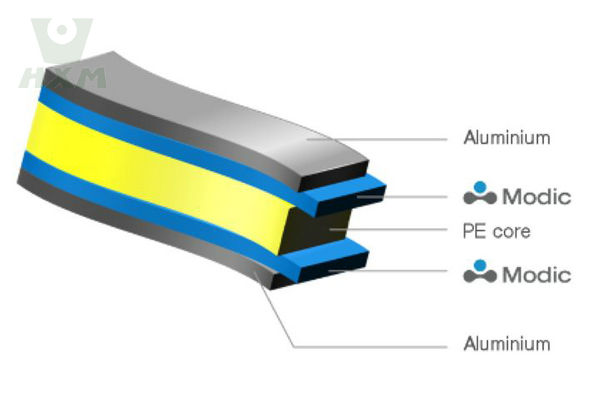

Aluminum composite sheets consist of two thin sheets of aluminum bonded to a polyethylene core. The aluminum is applied to the core during the manufacturing process, making it almost impossible to separate. The tough yet lightweight aluminum sheet has a very flat surface, making it ideal for screen printing, painting, and bonding decorative laminates. Our range of aluminum composite panels are premium 3mm sheets available in a wide range of colors and finishes.

Aluminum composite panels are faced during the manufacturing process to give them a smooth, consistent finish. Applications for aluminum composite panels sheets include splashbacks, signage, advertising stands, and wall cladding, among others.

Clad Aluminum Sheet Plate Specification

Thickness range

- Total thickness: 2mm – 6mm

- Aluminum plate thickness: 0.10mm – 0.50mm

- Core material thickness: adjusted according to total thickness

Width Range

- Standard width: 1000mm – 1500mm

- Common width: 1220mm, 1250mm

Length Range

- Standard length: 2440mm

- Customizable length: 1000mm – 6000mm, etc.

Core material

- Ordinary polyethylene core material (PE)

- Fireproof core material (FR)

Looking Forward to Becoming One of Your Aluminum Clad Plate Suppliers

Applications of Clad Aluminum Sheet

Building exterior wall decoration: Due to its beauty and weather resistance, aluminum composite panels are often used for building exterior wall decoration and curtain walls.

Indoor decoration: such as ceilings, partition walls, furniture surfaces, etc.

Billboards: Due to its lightness and easy processing characteristics, it is widely used in billboards and signboards.

Vehicle shell: the shell parts of trains, cars, ships, etc.

Features of Aluminum Composite Panel (ACP)

The aluminum Composite Panel (ACP) is a composite panel made of two layers of aluminum plates sandwiched with a core of non-aluminum material. This material is widely used in the fields of construction and advertising due to its lightness, high strength, easy processing, smooth surface, and strong weather resistance.

Lightweight: Aluminum composite metal panels are lightweight and easy to transport and install.

High Strength: Due to the structure, aluminum composite panels have good rigidity and strength.

Weather Resistance: The surface of aluminum composite metal panels has been treated to have good corrosion resistance and UV resistance.

Strong Decorative Effect: The surface can have a variety of colors, patterns, and even imitation stone and imitation wood effects to meet different design requirements.

Easy Processing: It can be easily cut, bent, and folded, suitable for various shapes and structures.

Looking Forward to Becoming One of Your Aluminum Composite Sheet Suppliers

Other Types of Aluminum Composite Panel

Aluminum composite panels (ACP) can be divided into many types according to different standards such as core material, surface treatment, application field, etc. The following are several common types of aluminum composite panels:

By Core Material

Standard ACP: Features a polyethylene (PE) core. It’s mainly used for interior decoration or exterior walls but has lower fire resistance.

Fire-Resistant ACP: Utilizes a fire-retardant mineral-filled core (e.g., magnesium-aluminum composite material). It offers better fire resistance, suitable for building exteriors and curtain walls where higher fire safety is required.

Non-Combustible ACP: Contains an inorganic core material, such as aluminum honeycomb or calcium silicate board. These panels have superior fire resistance, ideal for high-rise buildings and public facilities.

Looking Forward to Becoming One of Your Aluminum Composite Panel Distributors

By Surface Treatment

Sprayed ACP: The surface is spray-painted, offering a wide range of color options, suitable for building exteriors and interior decoration.

Coated ACP: The surface is roll-coated for uniform color and better weather resistance, commonly used for exterior walls.

Anodized ACP: The aluminum surface undergoes anodization, providing a metallic finish with excellent corrosion resistance, often used in premium architectural projects.

Laminated ACP: A decorative and protective film is laminated on the surface, which can simulate wood, stone, or a mirror finish. This type is used for both interior and exterior decoration.

By Functionality

Antibacterial ACP: The surface coating contains antibacterial properties, making it ideal for hospitals, food processing plants, and other hygiene-sensitive environments.

Anti-Static ACP: Features an anti-static surface, preventing the accumulation of static electricity, suitable for electronics factories and laboratories.

UV-Resistant ACP: The coating resists UV radiation, making it ideal for buildings exposed to prolonged sunlight.

By Application

- Building ACP: Primarily used for exterior wall decoration and curtain walls, requiring high durability and aesthetic appeal.

Advertising ACP: Designed for signage and billboards, requiring high flatness and vibrant colors.

Furniture ACP: Used for furniture surfaces, offering aesthetics, ease of cleaning, and wear resistance.

Looking Forward to Becoming One of Your Clad Aluminum Sheet Manufacturers

How to Make Aluminum Composite Panel (ACP)?

The production of Aluminum Composite Panels (ACP) involves several key steps that combine aluminum sheets, a core material, and adhesive layers to create a strong, flat, and weather-resistant composite material. Here’s an overview of the manufacturing process:

1. Raw Material Preparation

Aluminum Sheets: High-quality aluminum coils are selected, typically with a thickness of 0.2-0.5 mm. The surface of the aluminum sheets is pre-treated with processes like degreasing, chemical treatment, and coating to ensure good adhesion to the core material.

Core Material: Usually, polyethylene (PE) or fire-resistant core materials (such as mineral-filled materials) are used. The core is typically produced as thin sheets or boards through an extrusion process.

Adhesive: High-performance adhesives, such as hot-melt glue or other bonding agents, are used to securely bond the aluminum sheets to the core material.

2. Surface Coating

The aluminum sheets undergo surface coating to enhance their weather resistance and aesthetic appeal. Common coating methods include spray coating, roll coating, or anodizing. Coating materials can be polyester (PE), polyvinylidene fluoride (PVDF), or nano-coatings, depending on the application requirements.

3. Lamination Process

The lamination process is the core of ACP manufacturing, typically involving the following steps:

Heating the Aluminum Sheets and Core: Before entering the lamination machine, the aluminum sheets and core material are heated to a specific temperature to optimize the adhesive bonding.

Applying Adhesive: Adhesive is evenly applied between the aluminum sheets and the core material, ensuring a strong bond.

Laminating: The aluminum sheets and core material are pressed together through continuous lamination under high temperature and pressure, ensuring a flat and uniform panel.

Cooling and Curing: After lamination, the ACP is cooled to allow the adhesive to cure fully and to stabilize the panel’s structure.

4. Cutting and Shaping

The laminated ACP is then cut into specific sizes as per customer requirements. Additional shaping processes, such as edge folding or hole drilling, may be performed to meet the final application needs.

5. Quality Control

Before shipping, the ACP undergoes strict quality control tests to ensure it meets standards for thickness, flatness, bonding strength, and surface coating quality. Common tests include peel strength testing, weather resistance testing, and color consistency checks.

6. Packaging and Shipping

After passing quality checks, the ACP is carefully packaged to prevent damage during transportation. The panels are then shipped according to customer specifications.

Key Considerations in the Production Process

Temperature Control: Precise temperature control during lamination and cooling is crucial to ensure proper adhesion and the final quality of the panels.

Surface Treatment Quality: The uniformity, adhesion, and weather resistance of the coating directly impact the ACP’s durability and appearance.

Looking Forward to Becoming One of Your Clad Aluminum Sheet Manufacturers

Why Choose Huaxiao As Your Clad Aluminum Sheet Suppliers?

Choosing Huaxiao as your clad aluminum sheet supplier comes with several advantages that make it a preferred choice for many businesses. Here are key reasons why Huaxiao stands out:

1. High-Quality Products

Huaxiao is known for producing high-quality composite aluminium sheets. The company adheres to strict quality control processes to ensure that every product meets industry standards. This includes rigorous testing for properties such as strength, corrosion resistance, and surface finish, ensuring that customers receive reliable and durable materials.

2. Advanced Manufacturing Technology

Huaxiao uses advanced manufacturing technology and state-of-the-art equipment in its production processes. This ensures precision in the thickness, flatness, and bonding quality of the clad aluminum sheets. Their technological capabilities allow them to produce sheets that are consistent and meet the exact specifications required by clients.

3. Customizable Solutions

Huaxiao offers a wide range of customization options to meet the unique needs of their clients. Whether you need specific alloy compositions, thicknesses, surface finishes, or sizes, Huaxiao can tailor their products to suit your exact requirements. This flexibility is particularly beneficial for industries with specialized needs, such as automotive, aerospace, or architectural applications.

4. Competitive Pricing

Despite the high quality of their products, Huaxiao maintains competitive aluminium composite sheet prices. They offer cost-effective solutions without compromising on quality, making them an attractive option for companies looking to optimize their material costs while maintaining high standards.

5. Reliable Supply Chain

Huaxiao has a well-established and reliable supply chain that ensures the timely delivery of products. Their efficient logistics and inventory management systems help minimize lead times, ensuring that customers receive their orders when needed, which is crucial for maintaining production schedules.

6. Experienced and Knowledgeable Team

The team at Huaxiao is composed of experienced professionals who are knowledgeable about the materials and the industries they serve. They provide expert advice and support, helping customers choose the right products for their specific applications. Their customer service is responsive and focused on building long-term relationships.

We look forward to your choosing Huaxiao as one of your composite aluminum panel suppliers. We have advanced equipment, an excellent team, competitive prices and after-sales service, etc. Contact us now to get the product information and latest aluminium composite sheet prices!

Looking Forward to Becoming One of Your Clad Aluminum Sheet Distributors

FAQ

how to cut aluminum composite panel?

Laser cutting of aluminum composite metal panels

Shearing of aluminum composite panels

Cutting of aluminum composite metal panels using CNC routers

Cutting of aluminum composite metal panels using jigsaws

Cold chisels for cutting ACM panels

how to install aluminum composite panel?

The installation steps of aluminum composite material panels are as follows:

Draw lines: Draw horizontal lines along the ceiling according to the height of the house to mark the location of the keel installation.

Install the hanger: Use expansion bolts to fix the hanger on the roof.

Install the keel: Install the main keel (light steel keel) first, then install the secondary keel and the secondary keel is clamped on the main keel.

Sheet processing: Cut the aluminum composite panel according to the installation drawing. Before cutting, pay attention to the folding size of the reserved installation position and the folding groove of the sheet.

Install the aluminum composite panel: Insert the folding position of the aluminum composite sheet into the keel and fix it. When the keel is inserted and blocked, you can use a rubber hammer and a pad to tap and push it in.

Inspection and finishing: After the installation of the panel is completed, it should be inspected, repaired, and cleaned. After the overall inspection is correct, tear off the surface protective film.

how to clean aluminum composite panel?

The cleaning process of aluminum composite panels usually includes spray degreasing cleaning, brushing, spray rinsing, water absorption, air knife water blowing, hot air drying, etc. These steps together ensure the cleanliness and beauty of the aluminum composite metal panel surface.

Are aluminum composite materials fire-resistant?

Aluminum composite materials have good fire resistance. The middle of the board is a flame-retardant or non-combustible mineral polymer core material, and the outer surface is an extremely difficult to burn aluminum layer, so the whole has a good flame-retardant effect.

Can aluminum composite materials be curved or formed?

Aluminum composite materials can be bent or formed, but the following points should be noted:

Choose the appropriate bending method: According to the thickness of the aluminum composite sheet and the required bending shape, choose the appropriate bending method, such as hot press bending, cold bending, or V-groove bending.

Control temperature and pressure: During the bending process, control the temperature and pressure to avoid excessive deformation or breakage. Especially when hot press bending, control the heating time and temperature.

Inspect and treat the surface of the plate: Before bending, the aluminium composite sheet should be fully inspected to avoid scratches, wrinkles, or other damage on the surface. After bending, the surface of the plate should be cleaned and treated to maintain its flatness and aesthetics.

Contact Shanghai Huaxiao's Clad Aluminum Sheet Supplier Now