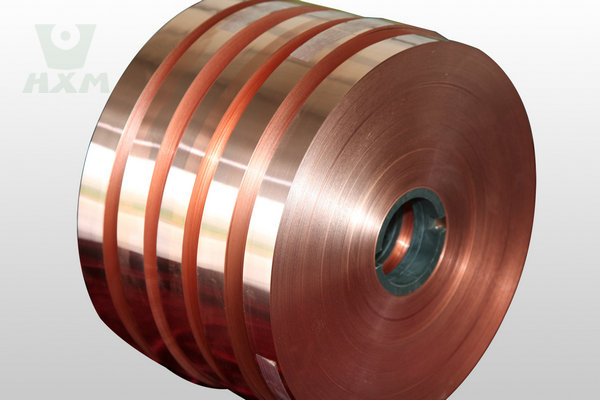

Copper Strip Supplier and Manufacturer From China

As a professional copper strip supplier, we not only provide high-quality products but also customized services to customers to ensure that the products meet the project requirements. Copper narrow strip is a key metal material widely used in many industries, such as electronics, electrical, and automobiles. Its excellent conductivity, corrosion resistance, and flexible molding characteristics make it an ideal choice for many high-precision projects.

As an excellent copper strip supplier, we have a large copper strip production factory. If you need to buy copper strip products, you can fill out the form to contact us and we will provide you with competitive copper strip prices.

Copper Strips Available For Sale

Grades: C11000, C10100, C10200, C12000, C14300, C14420, C14530, C44300, C70600, C71500, C17510, C19210, C19400, Tinned Copper, etc.

Thickness: 0.10mm – 6.35mm

Width: 3mm – 600mm

Surface Finishes: Oil-free surface, Electroplating, Hot-dip tin plating, Deburred or rounded edges, Bright and polished surfaces, Coil with protective coatings, Profiled coil by either milling or stamping

Standard: ASME, SAE, AMS, AWS, FED, MIL, QQ, ISO, BS, AFNOR and JIS.

What is copper Strip?

Copper strip generally refers to thin and narrow copper sheets. Its production process is complex and requires high precision, so it is widely used in high-demand industries. The conductivity and durability of copper tape make it excellent in the fields of electronic components, automobile manufacturing, and architectural decoration.

Features and Advantages

Excellent electrical conductivity: Copper strips have extremely high electrical conductivity and are suitable for manufacturing electrical and electronic components to ensure efficient and stable power transmission.

Corrosion resistance: In humid and corrosive environments, copper narrow strips can maintain their performance for a long time, and are particularly suitable for outdoor applications or projects in humid environments.

Good formability: Copper strips are easy to process into various shapes to meet the design requirements of different products.

High-precision manufacturing: Through precise rolling and cutting processes, copper strips can achieve extremely high dimensional accuracy, which is suitable for high-demand industrial applications.

Copper Strips Data Sheet

Chemical Composition Comparison

| Material | Cu | Zn | Sn | P | Other Elements |

|---|---|---|---|---|---|

| Pure Copper (C11000) | > 99.9% | — | — | — | Trace Oxygen (O) |

| Phosphor Bronze (C51000) | 94.8% | — | 4.5-5.5% | 0.03-0.35% | — |

| Phosphor Bronze (C52100) | 92.0% | — | 8.0-9.0% | 0.03-0.35% | — |

| Brass (C26000) | 68.5% | 31.5% | — | — | Trace Impurities |

| Brass (C28000) | 60-63% | 37-40% | — | — | — |

| Tinned Copper | > 99.9% | — | Coated with Tin (Sn) | — | — |

- Pure Copper (C11000): With a copper content close to 100%, it offers excellent electrical and thermal conductivity, making it ideal for electrical and electronic applications.

- Phosphor Bronze (C51000, C52100): Contains tin and phosphorus, enhancing fatigue resistance and corrosion resistance, suitable for springs and contacts requiring high strength and elasticity.

- Brass (C26000, C28000): High zinc content increases strength and wear resistance while maintaining good conductivity.

Physical Properties Comparison

The physical properties of copper strips vary between materials, including conductivity, thermal conductivity, and density. Here’s a comparison of the physical properties of common copper materials:

| Property | Pure Copper (C11000) | Phosphor Bronze (C51000) | Phosphor Bronze (C52100) | Brass (C26000) | Brass (C28000) |

|---|---|---|---|---|---|

| Density (g/cm³) | 8.93 | 8.8 | 8.8 | 8.47 | 8.4 |

| Electrical Conductivity (%IACS) | 100 | 15-20 | 10-15 | 28 | 24 |

| Thermal Conductivity (W/m·K) | 386 | 70-90 | 60-80 | 120 | 110 |

| Melting Point (°C) | 1083 | 900-1050 | 900-1050 | 905 | 920 |

- Pure Copper (C11000): Exhibits the highest conductivity (100% IACS) and thermal performance, making it ideal for electrical conductors and heat exchangers.

- Phosphor Bronze (C51000, C52100): Lower conductivity but high fatigue resistance, suitable for mechanical moving parts.

- Brass (C26000, C28000): Moderate conductivity and thermal conductivity, commonly used in mechanical and structural components.

Mechanical Properties Comparison

Copper strips must withstand various mechanical stresses, making it essential to understand their mechanical properties. Here’s a comparison of the mechanical properties of common copper materials:

| Property | Pure Copper (C11000) | Phosphor Bronze (C51000) | Phosphor Bronze (C52100) | Brass (C26000) | Brass (C28000) |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | 210-250 | 500-650 | 550-750 | 310-380 | 350-450 |

| Yield Strength (MPa) | 50-70 | 380-420 | 420-500 | 100-120 | 120-150 |

| Elongation (% in 50 mm) | 30-40 | 15-25 | 10-20 | 40-50 | 30-40 |

| Hardness (HV) | 40-80 | 150-200 | 160-210 | 90-110 | 110-140 |

- Pure Copper (C11000): Relatively low mechanical strength but excellent ductility, easy to process and form.

- Phosphor Bronze (C51000, C52100): High strength and hardness, especially suitable for applications requiring wear resistance and high-strength elasticity, such as springs and switches.

- Brass (C26000, C28000): Moderate strength and hardness, suitable for manufacturing mechanical parts and decorative materials.

Copper Strips Application

Copper narrow strips are widely used in many industries due to their excellent performance. The following are some common application areas:

Electronic Equipment:

Art and Decoration:

Where To Buy Copper Strip And Find Reliable Copper Strip Suppliers?

As a professional copper strip supplier and manufacturer, we not only provide a variety of spot stocks but also provide customized services according to customer needs. Whether you need standard specifications or specific requirements, we can provide you with solutions to meet your project needs.

Fast Delivery: We have sufficient inventory to ensure fast delivery and reduce your project delays.

Customized Production: Provide copper narrow strips of different thicknesses and widths according to customer requirements to meet the needs of various complex projects.

Global Customer Service: We provide high-quality services and technical support to customers around the world to ensure that every customer can enjoy a professional purchasing experience.

Whatever your project needs, we can provide high-quality copper strip products. Contact our supply team today to get product specifications, stock information and the latest quotes!

FAQ From Huaxiao Copper Strip Supplier

1. What is the minimum thickness of copper strip?

The minimum thickness of copper strip can reach 0.10 mm, which is suitable for various precision processing and electronic component manufacturing.

2. How to calculate the price of copper strip?

The price of copper strips depends on the purity, thickness, width, and order quantity of the material. We recommend that customers contact the sales team for an accurate quotation based on their specific needs.

3. How to ensure the quality of copper strip?

We use a strict production process and quality control system to ensure that each batch of copper strip meets international standards.

4. Production process of copper strip

The production process of copper strips determines its final quality, dimensional accuracy, and surface treatment effect. The following are the main production steps of the copper strip:

1. Rolling

Process Introduction: The production of copper strips starts with preliminary rolling, and the copper material is gradually pressed into the required thickness and width through the rolling mill. According to different thickness requirements, the rolling process can be carried out multiple times.

Process Characteristics: High-precision rolling can ensure the uniform thickness and smooth surface of the copper strip. We can provide products with a thickness range from 0.10 mm to 2.0 mm.

2. Annealing

Process Introduction: Annealing is to eliminate the internal stress generated during the rolling process, improve the ductility and plasticity of the copper strip, and make it less likely to break during subsequent processing.

Process characteristics: The annealed copper narrow strip is more flexible and suitable for the production of precision electronic components. We provide soft, medium-hard, and hard copper strip products according to customer needs.

3. Cutting and Slitting

Process Introduction: After rolling and annealing, the copper strip will be cut into strips to the required width. The high-precision slitting process ensures the stability and consistency of the width dimension.

Process Features: The slitting process can provide copper strips with a width range of 10 mm to 300 mm to meet the needs of different customers.

4. Surface Treatment

Process Introduction: The copper strip can be surface-treated according to different applications, such as bright annealing, wire drawing, or tinning. Surface treatment not only enhances the corrosion resistance of the copper strip but also improves its aesthetics and weldability.

Process Features: Bright copper strips are often used for decorative materials, while tinned copper strips are used for welding parts in electrical equipment.

5. Surface treatment types of copper strips

To meet different application requirements, copper narrow strips can be subjected to a variety of surface treatments to increase their durability and aesthetics in specific environments. The following are several common surface treatment methods:

1. Bright Surface Treatment (Bright Surface Treatment)

Features: Through polishing, the surface of the copper narrow strip is smooth and bright, suitable for decorative fields with high requirements for appearance.

Application: Mainly used in building decoration materials, interior design, furniture decoration, etc.

2. Oxidation Protection (Oxidation Protection)

Features: Through oxidation treatment, the corrosion resistance of copper narrow strips is significantly improved, and it is suitable for applications in humid or acidic environments.

Application: Suitable for outdoor building materials, electrical equipment housings, and other parts that need to be exposed to harsh environments for a long time.

3. Tinned Copper Treatment (Tinned copper)

Features: After the copper narrow strip is tinned, its surface oxidation resistance is greatly improved, and the welding performance is enhanced.

Application: Commonly used in products that require welding, such as cable conductors, electronic components, and electrical connectors.