Hastelloy Alloy Supplier and Manufacturer From China

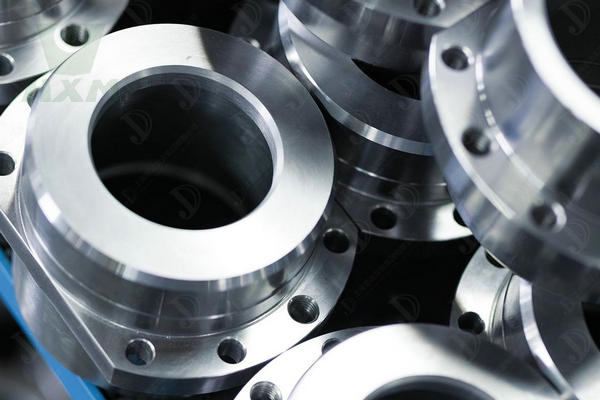

We provide high-performance Hastelloy Alloy materials designed to cope with corrosion, thermal stress, and high-temperature requirements in extreme environments. Whether it is chemical, pharmaceutical, marine engineering, or high-temperature processing equipment, Hastelloy has become the material of choice for many industries due to its excellent corrosion resistance, oxidation resistance, and mechanical strength.

Huaxiao Metal is a trusted Hastelloy supplier and manufacturer, committed to providing quality products that meet international standards. We have a rich inventory to ensure that you can get the Hastelloy stock you need at any time. Choose our Hastelloy to ensure that your equipment can maintain efficient and stable operation under the most challenging conditions. Contact us now to get a quote for Hastelloy or consult more detailed information about Hastelloy!

Hastelloy Alloy For Sale

Grades: HastelloyC276 HastelloyC22 HastelloyC2000 HastelloyC4 HastelloyG30 HastelloyB2 HastelloyB3 Hastelloy-X, etc.

Sizes: Custom sizes available

Shapes: Sheet/Plate/Bar/Tube/Strip/Coil/Wire, etc.

Standard: ASTM B575, ASTM B466, ASME SB-333, ISO 9453, UNS N06022, MIL-STD-129, DIN 17744, etc.

Our Hastelloy alloy stock is available in a variety of forms such as plates, sheets, bars, tubes and fittings to meet the specific needs of different industries.

Contact us today for detailed product specifications, availability and competitive Hastelloy alloy prices.

Hastelloy Alloy Data Sheet

Chemical Composition Comparison (%)

| Grade | Ni | Mo | Cr | Fe | Co | Other Elements |

|---|---|---|---|---|---|---|

| Hastelloy C-276 | 57% min | 15-17% | 14.5-16.5% | 4-7% | 2.5% max | Tungsten: 3-4.5%, Carbon: ≤0.01% |

| Hastelloy B-3 | 65% min | 28-30% | 1-3% | 5% max | 3% max | Carbon: ≤0.01%, Aluminum: ≤0.5% |

| Hastelloy X | 47% | 8-10% | 20.5-23% | 18% | 1.5% max | Tungsten: 0.2-1%, Silicon: ≤1% |

Physical Properties Comparison

| Grade | Density (g/cm³) | Melting Point (°C) | Thermal Conductivity (W/m·K) | Electrical Resistivity (μΩ·cm) | Coefficient of Thermal Expansion (10⁻⁶/°C) |

|---|---|---|---|---|---|

| Hastelloy C-276 | 8.89 | 1370 – 1425 | 10.2 | 1.28 | 11.0 |

| Hastelloy B-3 | 9.24 | 1330 – 1380 | 9.8 | 1.30 | 10.5 |

| Hastelloy X | 8.22 | 1260 – 1350 | 11.0 | 1.12 | 12.8 |

Mechanical Properties Comparison

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRC) | Impact Toughness (J) |

|---|---|---|---|---|---|

| Hastelloy C-276 | 790 – 950 | 355 – 450 | 40 – 50 | 20 – 30 | 120 – 150 |

| Hastelloy B-3 | 760 – 900 | 340 – 450 | 40 – 45 | 18 – 28 | 110 – 130 |

| Hastelloy X | 800 – 1000 | 380 – 480 | 35 – 45 | 22 – 32 | 100 – 140 |

As an experienced Hastelloy manufacturer, we optimize our production processes to offer competitive Hastelloy prices without compromising on quality. Contact us now for detailed product specifications, availability, and competitive Hastelloy Alloy prices.

Hastelloy Alloy Application

Hastelloy alloys are trusted in various high-stakes industries due to their robust properties:

Chemical Processing: Ideal for equipment exposed to aggressive chemicals, such as reactors, pipes, and heat exchangers.

Aerospace: Used in turbine engines and exhaust systems, offering outstanding high-temperature strength.

Pharmaceutical Industry: Suitable for manufacturing facilities where corrosion resistance and sanitary conditions are crucial.

Oil and Gas: Used in offshore drilling, pipelines, and other equipment exposed to saline and corrosive environments.

Nuclear Power: Ensures safety and reliability in reactor components exposed to high temperatures and radiation.

Hastelloy is one of the most suitable products for industries that require high corrosion resistance and durability. Due to its excellent performance in extreme environments, Hastelloy is widely used in chemical processing equipment, heat exchangers, pressure vessels and gas turbines. By choosing our Hastelloy products, you can ensure that your project is on track and the quality of your products is guaranteed. Contact us now to learn how our Hastelloy can add favorable conditions to your project.

Product Features of Hastelloy Alloy

Superior Corrosion Resistance: Hastelloy alloys exhibit excellent resistance to both reducing and oxidizing media, making them suitable for use in highly corrosive environments such as chemical processing and power plants.

High-Temperature Stability: Withstanding extreme heat, Hastelloy retains strength and resists oxidation, ideal for applications in industrial furnaces, chemical reactors, and gas turbines.

Enhanced Mechanical Performance: The unique composition of Hastelloy provides high tensile strength, durability, and the ability to perform under mechanical stress.

Our Hastelloy products offer maximum strength, corrosion resistance, and temperature stability. As a premium Hastelloy manufacturer, we guarantee that our products meet the highest industry standards, ensuring long-lasting performance even in the harshest conditions. With our extensive Hastelloy inventory, we can deliver fast. Contact us today to learn about Hastelloy prices and our inventory availability.

FAQ From Huaxiao Metal Supplier

What is Hastelloy Alloy?

Hastelloy is a family of nickel-based alloys known for their exceptional resistance to extreme environments. Composed primarily of nickel, molybdenum, and chromium, Hastelloy alloys maintain mechanical integrity and resist pitting, stress corrosion cracking, and oxidizing in harsh conditions.

Hastelloy type

Hastelloy B Type

- Representative models: Hastelloy B-2, Hastelloy B-3

- Main features: B series alloys contain a high proportion of nickel and molybdenum, have extremely low carbon and silicon content, and have excellent corrosion resistance in reducing environments (such as non-oxidizing acids such as hydrochloric acid).

- Application: Chemical processing industry, especially in equipment and systems that require resistance to reducing corrosion.

Hastelloy C Type

- Representative models: Hastelloy C-276, Hastelloy C-22, Hastelloy C-2000

- Main features: C series alloys are the most versatile and widely used Hastelloy alloys, containing nickel, chromium, and molybdenum, with excellent resistance to oxidation and reducing corrosion, and stable performance in high temperature and complex environments.

- Application: Widely used in chemical processing equipment, pollution control, pharmaceutical equipment, marine engineering, and high-temperature reactors.

G-type Hastelloy Alloy

- Representative models: Hastelloy G-30, Hastelloy G-35

- Main features: G series alloys are designed for phosphoric acid and other strong oxidizing acid environments, containing higher chromium and a small amount of copper, making them perform better in specific corrosive environments.

- Application: Used in fertilizer production equipment, hydrometallurgy and other applications that require resistance to strong oxidizing acid corrosion.

What are the disadvantages of Hastelloy?

The main disadvantages of Hastelloy include its high cost and potential difficulty in machining due to its hardness and strength.

Is Hastelloy better than stainless steel?

Hastelloy alloys are generally superior to stainless steel in terms of corrosion resistance and high-temperature stability, making them ideal for use in harsh corrosive environments. However, Hastelloy alloys are more expensive than stainless steel.

Hastelloy vs Stainless Steel

Which is better, Inconel or Hastelloy?

The choice between Inconel and Hastelloy depends on the application. Inconel is better for high-temperature applications, while Hastelloy offers superior corrosion resistance, particularly in chemical environments.

Hastelloy vs Inconel