Titanium Alloy Supplier and Manufacturer From China

Huaxiao Metal is a China and Asia wide supplier of metal and titanium raw materials to the industrial, petrochemical, precision engineering and metalworking industries.

We are a stockist with a large stock of ready to ship materials including bars, plates, sheets, clamps, tubes, pipes, wire, mesh and fasteners. We can supply a large stock of grades 1, 2, 4 and 5 (Ti-6Al-4V) and offer many other custom grades.

Our factory is ISO certified and we have an experienced technical sales team and ISO9001 certification from SGS.

If you want to purchase titanium alloy round bars, plates, sheets or coils, please contact us directly to get a quote or other product information.

China Titanium Alloy For Sale

Grades: TA1 TA2 TA3 TA10 TA18 TC4 Gr0 Gr1 Gr2 Gr3 Gr9, Ti 6AL-4V、Ti 6AL ELI、Ti 3Al 2.5、Ti 5Al-2.5Sn, etc.

Sizes: Custom sizes available

Shapes: Sheet/Plate/Bar/Tube/Strip/Coil/Wire, etc.

Standard: AMS 4911、4928、4967、6931, etc.

If you need a trustworthy and reliable supplier of titanium alloy sheets, titanium wires, and tubes, please contact us directly for a quote or additional product information.

Titanium Alloy Data Sheet - China Titanium Alloy Supplier

Titanium Alloy Grade Comparison Table

| Chinese Standard (GB) | American Standard (ASTM) | European Standard (EN) | Japanese Standard (JIS) | Main Composition | Applications |

|---|---|---|---|---|---|

| TA1 | Ti-0.2 (Grade 1) | Ti Grade 1 | Ti-1 | Ti + 0.1% O max | Chemical, aerospace, medical |

| TA2 | Ti-0.4 (Grade 2) | Ti Grade 2 | Ti-2 | Ti + 0.2% O max | Structural applications |

| TA3 | Ti-0.6 (Grade 3) | Ti Grade 3 | Ti-3 | Ti + 0.3% O max | Mechanical components |

| TA10 | Ti-6Al-4V (Grade 5) | Ti Grade 5 | Ti-6-4 | Ti + 6% Al + 4% V | Aerospace |

| TA18 | Ti-6Al-4V ELI | Ti 6-4 ELI | Ti-6-4 ELI | Ti + 6% Al + 4% V + 0.12% O max | Medical devices |

Our titanium alloy products offer a variety of similar grades to cover the needs of high-end fields such as aerospace, medical, and chemical industries. Whether you need Gr.5 (Ti-6Al-4V) or Gr.2 pure titanium, we can meet your specific requirements. By cooperating with trusted titanium alloy suppliers and manufacturers in China, we ensure that each batch of materials meets international standards, helping you reduce procurement risks and improve production efficiency.

Chemical Composition Comparison (%)

| Grades | Ti | Al | V | O | Fe | Other |

|---|---|---|---|---|---|---|

| TA1 (Gr1) | 99.5% min | – | – | 0.18% max | 0.2% max | H 0.015% max |

| TA2 (Gr2) | 99.2% min | – | – | 0.25% max | 0.3% max | H 0.015% max |

| TA3 (Gr3) | 99.0% min | – | – | 0.35% max | 0.3% max | H 0.015% max |

| TA10 (Gr9) | 90% min | 3.0% max | 2.5% max | 0.13% max | 0.25% max | H 0.015% max |

| TA18 | 99.0% min | – | – | 0.3% max | 0.25% max | Cu 0.1%, H 0.015% max |

| TC4 (Gr5) | 89.0% min | 6.0% max | 4.0% max | 0.2% max | 0.4% max | H 0.015% max |

| Gr0 | 99.8% min | – | – | 0.18% max | 0.2% max | H 0.015% max |

| Gr1 | 99.5% min | – | – | 0.18% max | 0.2% max | H 0.015% max |

| Gr2 | 99.2% min | – | – | 0.25% max | 0.3% max | H 0.015% max |

| Gr3 | 99.0% min | – | – | 0.35% max | 0.3% max | H 0.015% max |

| Gr9 (TA10) | 90% min | 3.0% max | 2.5% max | 0.13% max | 0.25% max | H 0.015% max |

Our titanium alloys are made of high-purity raw materials with composition strictly controlled within industry standards to ensure excellent corrosion resistance and mechanical properties.

Physical Properties Comparison

| Grade | Density (g/cm³) | Melting Point (°C) | Thermal Conductivity (W/m·K) | Thermal Expansion (10⁻⁶/K) | Electrical Resistivity (μΩ·m) |

|---|---|---|---|---|---|

| Ti 6AL-4V | 4.43 | 1660 | 6.7 | 8.6 | 240 |

| Ti 6AL ELI | 4.43 | 1660 | 6.7 | 8.6 | 240 |

| Ti 3Al 2.5 | 4.43 | 1660 | 6.6 | 8.5 | 220 |

| Ti 5Al-2.5Sn | 4.43 | 1660 | 6.5 | 8.4 | 210 |

Titanium alloys have low density, high melting point and excellent thermal stability, making them ideal for use in high temperature and corrosive environments. Our products are rigorously tested to ensure that physical properties such as thermal conductivity, electrical conductivity and coefficient of thermal expansion are at optimal levels. Whether you require small order quantities or large quantities, we have a large stock to meet your requirements. Contact us to obtain our stock information and product prices.

Mechanical Properties Comparison

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) |

|---|---|---|---|---|---|

| Ti 6AL-4V | 900 – 1100 | 828 – 896 | 10 – 15 | 300 – 350 | 4.43 |

| Ti 6AL ELI | 860 – 970 | 800 – 860 | 10 – 14 | 285 – 330 | 4.43 |

| Ti 3Al 2.5 | 800 – 950 | 758 – 850 | 12 – 18 | 270 – 320 | 4.43 |

| Ti 5Al-2.5Sn | 860 – 980 | 760 – 850 | 10 – 15 | 290 – 320 | 4.43 |

Titanium alloy has excellent strength to weight, our products excel in tensile strength, yield strength, and fatigue performance. By optimizing the production process, we ensure that the mechanical properties of each batch are stable and reliable to meet the needs of demanding industrial applications. We have sufficient stock and competitive titanium alloy prices. Contact us so your project can proceed smoothly.

Titanium Alloy Application - China Titanium Alloy Supplier

We offer a variety of ti alloy types, including but not limited to the following mainstream alloys:

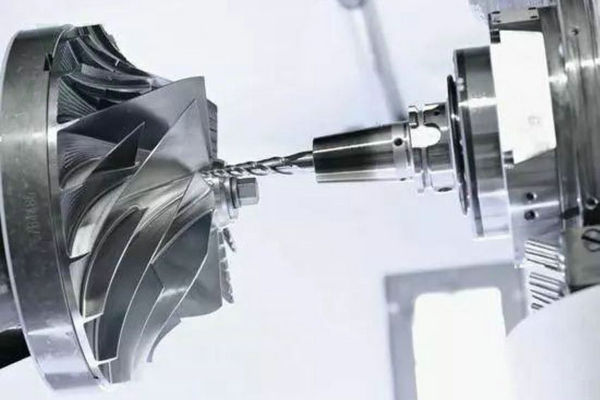

Ti-6Al-4V (Titanium Alloy 6AL-4V)

- Application: Widely used in aerospace structural parts, medical implants, and high-performance sports equipment.

- Features: High strength, good machinability, and excellent corrosion resistance, suitable for a variety of extreme environments.

Ti-3Al-2.5V

- Application: Widely used in aircraft and gas turbine structural parts and marine engineering equipment.

- Features: While maintaining high strength and good ductility, it is an ideal choice for applications with medium strength requirements.

Pure Titanium (CP Titanium)

- Application: Suitable for corrosion-resistant pipelines, chemical equipment, and marine engineering.

- Features: Pure titanium has excellent corrosion resistance and is suitable for chemical and biomedical equipment.

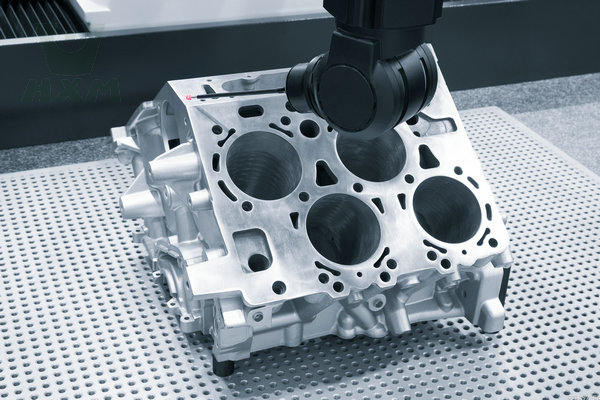

Titanium alloys are widely used in aerospace, medical equipment, marine engineering and automobile manufacturing. Our products have successfully served many world-renowned companies, helping customers improve product performance and reduce life cycle costs. By cooperating with high-quality alloy suppliers, we ensure that you can get high-performance materials at the best prices.

Product Features of Titanium Alloy - China Titanium Alloy Supplier

High strength-to-weight ratio: Titanium alloys are as strong as steel but only half as light, making them particularly suitable for applications that require lightweight.

Excellent corrosion resistance: They are extremely corrosion resistant in seawater, acidic, and alkaline environments, making them ideal for marine and chemical equipment.

Good biocompatibility: They do not contain toxic elements and are widely used in medical implants and biomedical devices, combining safety and stability.

High temperature resistance: They exhibit excellent stability at extreme temperatures and are often used in high-temperature environments in the aerospace industry.

Our titanium alloy products have high cost performance, stable performance and fast delivery as their core advantages. Whether it is a conventional model or customized requirements, we can provide comprehensive technical support and perfect after-sales service. With sufficient inventory and transparent prices, please feel free to contact us for the latest quotation and stock information to help your project complete smoothly!

FAQ From Huaxiao Metal Supplier

What is Titanium Alloy?

Ti alloys are widely used in a variety of high-performance fields, including aerospace, medical equipment, marine engineering, and the chemical industry, due to their light weight, high strength, corrosion resistance, and good biocompatibility. Titanium alloys can provide excellent performance when used to manufacture aircraft, ships, orthopedic implants, or chemical pipelines. We provide various titanium alloy materials and products to meet the diverse needs of customers.

Please feel free to contact us to learn about the supply, price, and inventory information of titanium alloys. Our professional team will provide you with efficient service!

Looking for titanium alloy suppliers that can handle both small batches and large industrial orders? Many manufacturers today require flexibility and fast lead times, especially for custom ti alloy specs. A good supplier isn’t just about stock—they should also offer processing options like cutting, forging, or machining to meet your project needs.

Does Titanium Rust?

Titanium will not rust but may form oxides or corrode under extreme conditions. Titanium metal have good corrosion resistance, especially in most environments, but may be affected under special conditions such as strong acids or alkalis.

What is the price of titanium alloy?

The price of titanium alloys will be affected by market fluctuations, specifications and quantities. You can contact our sales team at any time to get a detailed quotation, and we will provide the most competitive price according to your needs.

what metal is stronger than titanium?

Specially strengthened tungsten and titanium alloys are stronger than pure titanium. Tungsten has a higher tensile strength, while certain alloys, such as titanium aluminide, combine high strength with low weight.

How difficult is it to weld titanium alloy?

When welding titanium alloys, care must be taken to avoid oxidation, but good welding results can be obtained by using appropriate technology (such as argon arc welding).

What are the advantages of titanium alloy compared with stainless steel?

Titanium alloy is lighter than stainless steel and has significant corrosion resistance and strength advantages, so it is widely used in aviation, medical, and marine fields.

https://www.huaxiaometal.com/blogs/titanium-steel-vs-stainless-steel.html

How difficIs titanium alloy suitable for use in high temperature environments?ult is it to weld titanium alloy?

Yes, titanium alloys have high stability in high-temperature environments and are very suitable for aerospace and industrial high-temperature applications.