Valve Suppliers | Manufacturers In China

Professional Industrial China Valve Manufacturer

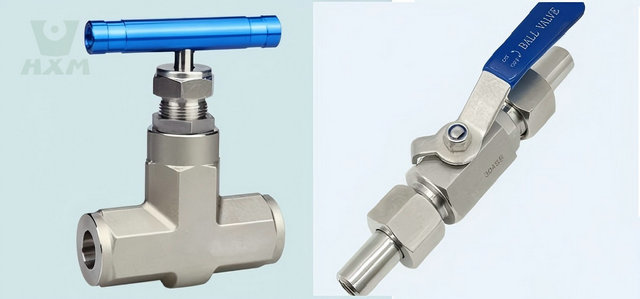

Gate valves, stop valves, check valves, hydrogenation valves, power station valves, ball valves, butterfly valves, regulating valves, special valves for aluminum plants, non-standard valves for special working conditions, etc.

We are a national high-tech enterprise integrating product design and development, mold making, casting and forging production, mechanical processing, performance testing and testing, marketing and service. The company is located in Shanghai, China, with superior geographical location and transportation conditions.

The company has a registered capital of 108 million yuan and covers a total area of 26,640 square meters, including 6,800 square meters of gate valve, stop valve and check valve workshops, 4,500 square meters of stainless steel valve workshops, 3,600 square meters of butterfly valve workshops, and 3,600 square meters of ball valve workshops. The company currently has more than 350 employees, 50 engineering and technical personnel, including 3 senior engineers, 15 engineers, and 32 assistant engineers and technicians.

Are you looking for valve suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Valve Products For Sale From China Valve Suppliers

Valve Products: gate valves, stop valves, check valves, hydrogenation valves, power station valves, ball valves, butterfly valves, regulating valves, special valves for aluminum plants, non-standard valves for special working conditions, etc.

Nominal diameter: 10mm~4000mm and 1/2″~160″

Working pressure: 0.25MPa~76.0MPa/150Lb~4500Lb/10K~320K

Working temperature: -196℃~816℃

Adopted standards: GB, DIN, API, ANSI, JIS, BS, etc.

Product materials: QT450, WCB, A105, L CB, LF2, WC6, F11, WC9, F22, ZG1Cr5Mo, F5, ZG20CrMoV, ZG15Cr1Mo1V, 12Cr1MoV, C12A, F91, F92, CF8, F304, CF8M, F316, CF3, F304L, CF3M, F316L, CF8C, F347, F304H, F316H, F321H, 4A, F51, 5A, F53, Inconel, Monel, copper alloy, titanium alloy, Hastelloy, nickel alloy, etc.

Are you looking for valve suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Table of Contents

Valve Material Specifications

| Material Code | Chinese Name | Application Medium | Operating Temperature Range |

|---|---|---|---|

| WCB | Carbon Steel | Non-corrosive applications, including water, oil, and gas | -30℃ to 425℃ |

| LCB | Low-Temperature Carbon Steel | Low-temperature applications, not suitable for temperatures above 340℃ | Down to -46℃ |

| LC3 | 3.5% Nickel Steel | Low-temperature applications, not suitable for temperatures above 340℃ | Down to -101℃ |

| WC6 | 1.25% Chromium 0.5% Molybdenum Steel | Non-corrosive applications, including water, oil, and gas | -30℃ to 593℃ |

| WC9 | 2.25% Chromium | Non-corrosive applications, including water, oil, and gas | -30℃ to 593℃ |

| C5 | 5% Chromium 0.5% Molybdenum | Mildly corrosive or erosive and non-corrosive applications | -30℃ to 649℃ |

| C12 | 9% Chromium 1% Molybdenum | Mildly corrosive or erosive and non-corrosive applications | -30℃ to 649℃ |

| CA6NM | 12% Chromium Steel | Corrosive applications | -30℃ to 482℃ |

| CA15 | 12% Chromium | Corrosive applications | Up to 704℃ |

| CF8M | 316 Stainless Steel | Corrosive, ultra-low, or high-temperature non-corrosive applications | -268℃ to 649℃; carbon content ≥0.04% required for temperatures >425℃ |

| CF8C | 347 Stainless Steel | Primarily for high-temperature corrosive applications | -268℃ to 649℃; carbon content ≥0.04% required for temperatures >540℃ |

| CF8 | 304 Stainless Steel | Corrosive, ultra-low, or high-temperature non-corrosive applications | -268℃ to 649℃; carbon content ≥0.04% required for temperatures >425℃ |

| CF3 | 304L Stainless Steel | Corrosive or non-corrosive applications | Up to 425℃ |

| CF3M | 316L Stainless Steel | Corrosive or non-corrosive applications | Up to 454℃ |

| CN7M | Alloy Steel | Excellent resistance to hot sulfuric acid | Up to 425℃ |

| M35-1 | Monel | Weldable grade, excellent resistance to common organic acids and saltwater, also high resistance to most alkaline solutions | Up to 400℃ |

| N7M | Hastelloy B | Ideal for various concentrations and temperatures of hydrofluoric acid, excellent resistance to sulfuric and phosphoric acid | Up to 649℃ |

| CW6M | Hastelloy C | Excellent resistance to strong oxidizing environments, great performance at high temperatures, high corrosion resistance to formic acid, phosphoric acid, sulfurous acid, and sulfuric acid | Up to 649℃ |

| CY40 | Inconel | Excellent performance in high-temperature applications, superior corrosion resistance for aggressive fluid media | Up to 649℃ |

Carbon molybdenum steel (WC1), nickel-chromium-molybdenum steel (WC4, WC5), chromium-molybdenum steel (WC6, WC9, WC11, C5, C12) and chromium-molybdenum-vanadium steel (CA12, CA15). The W in steel represents weldability, indicating that it has good welding performance.

C represents Cr-containing cast steel, and the following numerical value represents the order of high and low applicable working temperatures of high-temperature alloy steel. The larger the numerical value, the higher the applicable temperature.

LCC, the full name of low-temperature carbon steel, is a low-carbon steel designed for cold regions. Its characteristic is that the carbon content is less than 0.25%, and it is usually used in the manufacture of low-temperature valves.

According to the ASTMA352/A352M standard, it is suitable for low-temperature environments of -4 to 60℃. LCC steel is also called soft steel due to its low strength and hardness. It is mainly composed of ordinary and high-quality carbon structural steel. Most of it is used for engineering structural parts without heat treatment. For mechanical parts that require wear resistance, carburizing, and other heat treatments can be performed.

Are you looking for valve suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Valve Connection Method

The connection types of valves are divided into: flange connection, welding connection, threaded connection, ferrule connection, clamp connection, and clip connection.

Flange Connection

The valve body has flanges at both ends, which correspond to the flanges on the pipeline and are installed in the pipeline by bolting the flanges. For pipelines with DN>50, flange connection is the most commonly used connection form in valves. Flanges have convex surface (RF), flat surface (FF), convex concave surface (MF), etc. Flange-connected valves are easy to install and disassemble, and the nominal size and nominal pressure used are very wide. The selection of various flange sealing surface forms depends on different applicable working conditions.

Welded Connection

This structure is suitable for various pressures and temperatures, and is more reliable than flange connection when used under harsh working conditions. However, it is difficult to disassemble and reinstall valves with welded connections, so its use is limited to occasions where it can usually operate reliably for a long time, or where the operating conditions are harsh and the temperature is high. For example, pipelines in thermal power plants, nuclear power projects, and ethylene projects.

Are you looking for aluminium suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Threaded Connection

Threaded connection is often used for small valves. Threaded connection is mostly used in situations where welding is not suitable or disassembly is required. It has good sealing effect. For > DN50 threaded connection, it can be used for non-hazardous fluids, but its connection is not easy to control, and it is difficult to apply enough torque to tighten the connection joint without damaging the components. Therefore, threaded connection is mostly used in pipelines ≤ DN50 without hazardous fluids.

Ferrule Connection

The characteristic of ferrule connection is that it relies on the cutting edge of the ferrule to tightly bite the steel pipe wall, so that the high-pressure fluid in the pipe is completely sealed. This connection structure has the advantages of tight connection, impact resistance, good vibration resistance, easy maintenance, fire and explosion prevention, high pressure resistance, and good sealing performance. It is an advanced connection method in power stations, oil refineries, chemical plants and instrument measurement pipelines.

Are you looking for aluminium suppliers?

REQUEST A QUOTE FOR MORE DETAILS

Clamp Connection

Clamp connection is a quick connection method. Compared with welding and flange connection, the pipeline system has better stability and is more suitable for temperature changes, thus protecting the pipeline components and reducing the damage to the structural parts caused by pipeline stress. It is simple to operate, requires less operating space, and is easy to maintain. It is widely used in extreme operating conditions such as sanitary conditions and quick disassembly.

Wafer Connection

Wafer connection valve refers to a connection form in which the valve is installed between two flanges, and the valve and the two pipes are directly clamped together with bolts. There are usually positioning holes on the valve body to facilitate installation and positioning, which can prevent the valve from radial displacement during maintenance or replacement of gaskets. Wafer connection valves are essentially flange connection valves. The seal is formed by the compression force of the flanges on both sides. Its installation method has the characteristics of flange connection and is mostly used for the installation of butterfly valves.

Are you looking for valve manufacturers?

REQUEST A QUOTE FOR MORE DETAILS

Valves Production Standards

American Standards (ASME and API Valves)

| Category | Standard |

|---|---|

| Design and Manufacturing Standards | |

| Gate Valve | API 600 or API 6D |

| Forged Steel Gate Valve | API 602 |

| Globe Valve | BS 1873 or ASME B16.34 |

| Forged Steel Globe Valve | API 602 |

| Check Valve | API 6D or BS 1868 |

| Forged Steel Check Valve | API 602 |

| Ball Valve | API 6D or API 608 |

| Butterfly Valve | API 609 or AWWA C504 |

| Length Standard | ASME B16.10 |

| Flange Standard | ASME B16.5 (NPS < 24) or ASME B16.47 (NPS > 26) |

| Welding End Standard | ASME B16.25 |

| Visual Inspection Standard | MSS SP54 |

| Inspection and Testing Standards | API 598, API 6D, or API 600 |

| Pressure and Temperature Rating | ASME B16.34 |

Common design, manufacturing, and inspection standards for American standard valves

1. Name: Pipeline valve specification (equivalent to ISO14313-2007)

Design and manufacturing: API6D-2008

Scope of application: Design, manufacture, testing, and documentation of ball valves, check valves, gate valves, and plug valves for pipeline systems in the oil and gas industry that meet the requirements of ISO13623. This international standard does not apply to valves with a rated pressure exceeding PN42.0MP (2500LB). This standard does not apply to submarine pipeline valves

Structural length: (this standard) or ASMEB16.10-2000

Connecting flange: ASME B16.5-1996 (DN≤600 does not include DN550); ASME B16.47A series (DN≥650); DN550 (NPS22) flange complies with: MSS SP-44

Inspection and testing: (ISO5208) This standard

2. Name: flanged, lug, wafer, and butt-welded check valves

Design and manufacturing: API594-2004

Scope of application: This international standard includes the design, materials, structural length, pressure-temperature ratings, inspection, inspection, and testing requirements for two types of check valves. Type A check

valve: short structural length, can be: wafer type, lug type,e or double flange type; single plate or double plate; gray cast iron, ductile iron, steel, nickel alloy, or other alloys, can be installed between 125-pound and 150-pound ductile iron flanges by ASME B16.1, between 150-2500-pound steel flanges by ASME B16.5, between 150-600-pound steel pipe flanges by MSS SP-44 or between carbon steel flanges by ASME B16.47. Type B check valve is a long structural length, and can be flanged or butt-welded; steel, nickel alloy, or other alloys, can be installed between 150-2500-pound steel flanges by ASME B16.5 or butt-welded to industrial piping systems.

Structural length: This standard

Connecting flange: ASME B16.1, B16.5, B16.47, MSS SP-44

Inspection and testing: API598

3. Name: Steel gate valves, stop valves, and check valves with nominal size less than and equal to DN100 for petroleum and natural gas industries

Design and manufacturing: API602-2005 (ISO15761)

Scope of application: This international standard specifies the requirements for a series of compact steel gate valves, stop valves, and check valves for the petroleum and natural gas industries. Nominal sizes are: 8, 10, 15, 20, 25, 32, 40, 50, 65, 80, 100; applicable pound classes are: 150, 300, 600, 800, and 1500 pound classes; specific regulations are as follows: socket welding or threaded end: 8≤DN≤65, pressure is 800 and 1500LB; flange end or butt welding end: 15≤DN≤100; 150≤pressure≤1500 does not include 800 pound flange end;

Structural length: ASME B16.10 (ASME B16.11: socket welding and threaded connection)

Connection flange: ASME B16.5 (when the valve body end is a tapered pipe thread: ISO7-1 or ASME 131.20.1)

Inspection and testing: API598

4. Name: Double flange, lug and wafer butterfly valve

Design and manufacturing: API609-2004

Scope of application: This standard includes: gray cast iron, ductile iron, bronze, steel, and nickel alloy or special alloy butterfly valves. There are two types: Class A: a concentric butterfly plate and valve seat, pressure

rating: 125 or 150 pounds, pipe diameter NPS2 to 48 inches. Category B: one eccentric valve seat and one eccentric or concentric butterfly plate structure, lug type, and wafer type, pressure rating: 150, 30,0 and 600 pounds, pipe diameter NPS3 to 24 inches; double flange long type: pressure rating 150, 300 and 600 pounds, pipe diameter NPS3 to 36; double flange short type: pressure rating 150 and 300 pounds, pipe diameter NPS3 to 48; double flange short type, 600 pounds, nominal pipe diameter NPS3 to 24

Structural length: this standard

Connecting flange: between flanges of ASME and MSS standards and specifications

Inspection and testing: API598

5. Name: Metal ball valve with flange, thread, and welding connection

Design and manufacturing: API608-2002

Scope of application: Applicable to 1/2 to 12in butt welding connection or flange connection and threaded connection or socket welding connection with nominal diameter 1/2 to 12in, by ASME Metal ball valves with B36.10 nominal pipe diameter and for opening and closing pressure rating: 150 and 300LB flange connection and butt welding connection; 150, 300 and 600LB threaded connection and socket welding connection valves.

Structural length: flange and butt welding ASME B16.10 (thread and socket welding according to manufacturer’s standard)

Connection flange: flange: ASME B16.5 (socket welding and threaded ASME B16.11; butt welding end: ASME B16.25)

Inspection and testing: API598

Are you looking for valve manufacturers?

REQUEST A QUOTE FOR MORE DETAILS

German Standards

| Category | Valve Type | Standard |

|---|---|---|

| Design and Manufacturing Standards | ||

| Gate Valve | DIN 3352 | |

| Globe Valve | DIN 3356 | |

| Check Valve | DIN 3356 | |

| Ball Valve | DIN 3357 | |

| Butterfly Valve | DIN 3354 | |

| Length Standard | DIN 3202 | |

| Flange Standard | DIN 2543-2545 | |

| Welding End Standard | DIN 3239 | |

| Inspection and Testing Standards | DIN 3230 | |

| Pressure and Temperature Rating | DIN 2401 |

European Union Standards

| Category | Valve Type | Standard |

|---|---|---|

| Design and Manufacturing Standards | ||

| Gate Valve | EN 10434 | |

| Globe Valve | EN 13709 | |

| Ball Valve | EN 13709 | |

| Check Valve | EN 10739 | |

| Length Standard | EN 558 | |

| Flange Standard | EN 1092 | |

| Inspection and Testing Standards | EN 12266 | |

| Welding End Standard | EN 12627 |

Are you looking for valve manufacturers?

REQUEST A QUOTE FOR MORE DETAILS

British Standard (BS) for Valves

| Valve Type | British Standard (BS) |

|---|---|

| Gate Valve | BS 1414 |

| Globe Valve | BS 1873 |

| Check Valve | BS 1868 |

| Ball Valve | BS 5351 |

| Butterfly Valve | BS 5155 |

| Weld End Standard | BS 2080 |

| Flange End Standard | BS 4504, BS 1560 |

| Inspection Standard | BS 5146 |

| Pressure-Temperature Standard | BS 12516, BS 1560 |

| Fire Protection Standard | BS 6755 |

Japanese Standard (JIS) for Valves

| Valve Type | Japanese Standard (JIS) |

|---|---|

| Gate Valve | JIS B2073, 2083 |

| Globe Valve | JIS B2071, 2081 |

| Check Valve | JIS B2074, 2084 |

| Ball Valve | — |

| Butterfly Valve | — |

| Structure Length Standard | JIS B2002 |

| Flange Size Standard | JIS B2212, 2214 |

| Pressure-Temperature Standard | JIS B2073, 2083 |

| Pressure Testing Standard | JIS B2003 |

Chinese Standard (GB) for Valves

| Valve Type | Chinese Standard (GB) |

|---|---|

| Gate Valve | GB/T 12234 |

| Globe Valve | GB/T 12235 |

| Check Valve | GB/T 12236 |

| Ball Valve | GB/T 12237 |

| Butterfly Valve | GB/T 12238 |

| Structure Length Standard | GB/T 12221 |

| Flange Standard | GB 9113 or JB 79, GB 13402 (large diameter) |

| Weld End Standard | GB/T 12224 |

| Pressure-Temperature Standard | GB/T 12224 |

| Inspection and Pressure Testing Standard | GB 13927 or JB 9092 |

Are you looking for the valve factory?

REQUEST A QUOTE FOR MORE DETAILS

Valves PN

Nominal Pressure (PN) refers to the pressure strength of pipeline components at a reference temperature, and it is measured in MPa (Megapascals). For example, a nominal pressure of 1.0 MPa is denoted as PN 10.

The reference temperature for materials may vary (e.g., the reference temperature for steel is 250°C).

Common Nominal Pressure Conversion and Expressions:

| Unit | Conversion |

|---|---|

| MPa | 1 MPa = 1000 kPa |

| PN | PN 10 = 1 MPa |

| Bar (kgf) | 10 Bar = 1 MPa |

| PSI (lbf) | 1 PSI = 6.8948 kPa ≈ 6.9 kPa |

Pressure Class Conversion (Class to PN)

| Class | Nominal Pressure at 120°C (MPa) | PN |

|---|---|---|

| 150 | 0.6 MPa | PN 6 |

| 300 | 1.0 MPa | PN 10 |

| 400 | 1.6 MPa | PN 16 |

| 600 | 2.0 MPa | PN 20 |

| 900 | 2.5 MPa | PN 25 |

| 1500 | 4.0 MPa | PN 40 |

| 2500 | 5.0 MPa | PN 50 |

Note:

- PN values below 1.6 MPa are considered Low-Pressure Valves.

- PN values between 2.5 MPa and 6.4 MPa are considered Medium-Pressure Valves.

- PN values above 10.0 MPa are considered High-Pressure Valves.

Class Pressure Rating Conversion (American Standard)

| Class | Pressure at 454°C (MPa) | PN Equivalent |

|---|---|---|

| Class 150 | 1.034 MPa | PN 10 |

| Class 300 | 2.068 MPa | PN 25 |

| Class 400 | 2.758 MPa | PN 40 |

| Class 600 | 4.137 MPa | PN 64 |

| Class 900 | 6.206 MPa | PN 100 |

| Class 1500 | 10.343 MPa | PN 150 |

| Class 2500 | 17.238 MPa | PN 250 |

Important Notes:

- The conversion between PN and Class is not always exact because the temperature reference differs. PN (European standard) uses 120°C as the reference temperature, while Class (American standard) uses 454°C.

- For Class 150, the nominal pressure is typically around 2.0 MPa at room temperature, whereas at 260°C, its allowable stress is 1 MPa.

Determining the Rated Pressure

To determine the rated pressure of a pipeline component, consider the following three factors:

- Material Group

- Temperature

- Nominal Pressure Rating

Are you looking for the valve factory?

REQUEST A QUOTE FOR MORE DETAILS

Valve Nominal Diameter and Inch Conversion Table

The following table shows the conversion between Nominal Diameter (DN) and Inches (in) for valve sizing:

| Nominal Diameter (DN) | Inches (in) |

|---|---|

| 15 | 1/2 |

| 20 | 3/4 |

| 25 | 1 |

| 32 | 1 1/4 |

| 40 | 1 1/2 |

| 50 | 2 |

| 65 | 2 1/2 |

| 80 | 3 |

| 100 | 4 |

| 125 | 5 |

| 150 | 6 |

| 200 | 8 |

| 250 | 10 |

| 300 | 12 |

| 350 | 14 |

| 400 | 16 |

| 450 | 18 |

| 500 | 20 |

| 600 | 24 |

| 700 | 28 |

| 800 | 32 |

| 900 | 36 |

| 1000 | 40 |

Contact Shanghai Huaxiao's Valve Product Supply now

Whether you’re looking forGate valves, stop valves, check valves, hydrogenation valves, power station valves, ball valves, butterfly valves, regulating valves, special valves for aluminum plants, non-standard valves for special working conditions, etc, we’ve got you covered. Contact us today to learn more about our valve prices!